The new offerings from Mopar are a breath of fresh air for those of us unable to purchase a rear-wheel-drive V-8-powered automobile from Chrysler Corporation until recently. And while you may or may not like the fuel injection and electronics on your new Mopar, you must admin doing a burnout with a Hemi under the hood and smoke coming from the rear tires is how it was meant to be. The amenities of late-model Mopars are also easy to get used to, as is the reliability of driving a newer automobile. We couldn’t wait to get ours, which meant opting for the automatic transmission version since those were the first ’09 R/Ts produced. We’ve really enjoyed driving our Challenger, and while the Nag1 five-speed automatic transmission has worked perfectly so far, we know we’re pushing our limits since our engine is modified with a Procharger intercooled supercharger kit.

Since owning our Challenger R/t, we’ve lowered the car with an Eibach sport suspension kit, adding larger diameter sway bars as well to improve the handling characteristics, and also installed Magnaflow exhaust. We’ll be addressing other areas of our vehicle, such as lightening it up, improving the brakes, upgrading the wheels and tires, and increasing the fuel system’s volume in future articles as we prepare for the ultimate goal of replacing the factory engine with a larger displacement version containing forged internals. This month we’ll continue our modifications, upgrading our car’s automatic transmission with a high-performance replacement NAG1 Performance Transmission from Gearstar.

The professionals at Gearstar Performance Transmissions are known for the quality of their engineered transmission and torque converter assemblies, can provide a transmission to fit any of your needs, from mild to wild, and even have a NAG1 unit in a Jeep SRT8 that is rumored to run the quarter-mile in the 8s. They build TorqueFlite transmissions as well, delivering any level of performance desired, and each transmission is assembled by a dedicated builder, then dyno tested when complete. Since the NAG1 transmission in our Challenger will be used not so much for racing but in a moderately powered street car, Gearstar prepped ours to easily handle the power our combination will make, and has NAG1 units avialble to handle up to 1,100 lb-ft of torque and 1,100 horsepower. As part of the package, they also sent a well matched converter for our combination, with much improved lockup clutch capacity. And if we need a beefier transmission in the future, we can just send our unit back to Gearstar for the latest upgrades.

Before simply swapping the transmission, let’s discuss Mopar’s new automatic, what led to it, and how it works. When the LX cars were debuted in 2005, Daimler still owned a big chunk of Chrysler Corporation, and the companies obviously shared technology freely. Throughout the Charger, Magnum, 300, and Challenger, you can see the Mercedes engineering in the suspension and brakes, and even in areas like the door seals. This thoroughbred influence was good for Chrysler, resulting in well-engineered cars that are fun to drive and technologically sophisticated, with computers controlling nearly every aspect of the vehicle, including the transmission. Designated by Chrysler as the NAG1 five-speed automatic, the unit is actually a Mercedes part number 722.6 transmission that dates back to 1996.

Used primarily in passenger cars, the Mercedes 722.6 (NAG1) is a hydraulic automatic transmission with many similarities to older designs but many differences as well. Instead of using hydraulic pressure, valves, and a governor to control up and downshifts, the NAG1’s valvebody contains a series of computer actuated relays to control these functions. Additionally, the converter is a lockup model, again with a computer controlling when the convert locks up partially, or completely. AS you’re noticing, this is a sophisticated unit, using planetary gear sets, multiple clutch packs, and even internal brakes, which is why we didn’t take the chance of upgrading it ourselves.

Through their research both in the shop and at the track, the team at Gearstar Performance Transmissions has identified any weak links in the NAG1 and corrected them so their transmissions can withstand 1,100 lb-ft of torque, far more torque than a factory unit is capable of enduring. Each transmission is fully disassembled and cleaned, and then all of the tolerances are checked and corrected before the transmission is assembled using heavy-duty components. All of the internal parts are cryogenically treated and stress relieved, and the second, third, and fourth gear clutch drums are modified fro expanded capacity. Gearstar uses high-energy clutches, updates the input-to-output shaft bearing support, and uses a special sprag assembly. Internal fluid pressure is increased for proper lubrication as well.

To control the transmission, the valve-body is reprogrammed and new electronics are installed. A billet torque converter is designed for each application, featuring a custom stall speed and CNC machined precision. The lockup clutch is also modified for increased capacity, which improves durability as well as performance. Once we got our new transmission, we head up to Inline Performance Specialists in nearby central Florida to get a hand installing the unit. With the help of the technicians at Inline, we had our transmission and converter swapped in an easy half day and were ready for a test drive.

Our first impression of the Gearstar NAG1 was a much crisper overall feel. When the gear selector was placed in a forward or reverse gear, we felt the transmission engage firmly, and throttle response was crisp when driving in any gear. AFter a little moderate cruising to allow everything to come up to temperature, we ran the transmission through it’s paces and were pleasantly surprised. The transmission has firmer up and downshifts than the stock transmission, though the shifts are still comfortable and not abusive. The converter is definitely looser as well, allowing tire spin at just about any point through first and second, indicating we’ll need some stickier tires before doing any real track testing. Thanks to the looser converter and tighter transmission, throttle response is noticeably better, and the car is more reactive to throttle input whether part of full throttle.

We know this transmission and converter package have made our Challenger quicker just by the sensation we get from driving the car. It would be a shame to do any track testing with our factory tires, however, as the inevitable tire spin wouldn’t allow us to show you the real improvements we’ve made. Look for a future article as we upgrade the wheels and install stickier tires on our Challenger, and we’ll take our late-model muscle car to the dragstrip for some real testing.

|

As one of the only cars we’ve purchased new, the styling and performance of the latest Challenger was a big hit with us. And finally having a two-door, rear-wheel-drive, V-8-powered Mopar is good payoff for sticking with Chrysler during the K-car years. |

|

|

Since owning this car, we’ve performed several modifications, including a Procharger supercharger system that netted 100 additional rear-wheel horsepower, and sport suspension from Eibach for better handling. |

|

We’ve enjoyed owning and driving our Challenger so far and eventually plan to replace the powerplant with a larger displacement unit. We don’t want to damage our factory drivetrain components, though, so this month we’ll upgrade with a high-performance five-speed automatic from Gearstar Performance Transmissions. |

|

|

Located in Akron, Ohio, Gearstar Performance specializes in building some of the most durable and best performing transmissions in the business and has tested its NAG1 modifications in several high-performance vehicles, including this all-wheel-drive Jeep SRT8 that runs single digit quarter-mile times. |

|

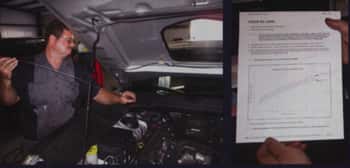

Every transmission is built to the best specifications based on the application. Once a transmission builder is assigned to a transmission, he stays with it until completion, assuring a quality product. |

|

|

Gearstar performs multiple modifications to improve shift quality and durability, including cryogenically stress-relieving all of the internal parts and expanding the capacity of the second, third, and fourth gear clutch packs. |

|

The Chrysler NAG1 is identical to a Mercedes transmission with the designation 722.6, just with the proper bellhousing to fit the Mopar engine, in our case the 5.7 Hemi. While they wouldn’t tell us all the tricks they employed, we do know Gearstar upgrades the input to output bearing support, and internal pressure is increased for improved lubrication. |

|

|

Each transmission’s valvebody is disassembled and reprogrammed and new electronics are installed. The NAG1 is a modern transmission, completely controlled by the car’s computer, wiring, and a series of solenoids on the valvebody. Offering better gear-reduction and overdrive, the NAG1 is light-years ahead of older three-speed models. |

|

The torque converter is a full-billet unit from Gearstar Performance, set up specifically for our application with a custom stall speed. The lockup clutch is also upgraded for increased load capacity, a necessity in high-torque applications. |

|

|

Once completed, our NAG1 was run on Gearstar’s transmission dyno, ensuring all of the parameters, including shift firmness and the stall speed of the converter are correct. It’s nice to know our unit will work properly and be leak free prior to installing it. |

|

Our transmission was shipped complete, with the converter already installed, so all we had to do was swap it into the Challenger. Since the lift was occupied in our shop, we took advantage of Inline Performance Specialists’ offer to lend us one of their lifts. |

|

|

Removing a late-model transmission is basically like removing any automatic. Once the linkage and wiring harness are disconnected, the converter bolts can be loosened and the crossmember and bellhousing bolts are removed last. It definitely helps to have a lift and transmission jack to accomplish this swap. |

|

The driveshaft doesn’t have universal joints, but couplers at the front and rear to connect the transmission to the differential. The front coupler needs to be removed and installed on the new transmission prior to installing the transmission. |

|

|

Since the upgraded transmission is externally the same as the one we removed, installation is straightforward. Be sure to disconnect the battery as the starter has to be removed and the wires could contact a ground and cause a fire hazard. |

|

The Gearstar transmission comes with fluid in it, so we just need to top it off with fluid. The problem is that like most modern cars, the Challenger has no dipstick to use. Fortunately, Inline has the kit which includes the dipstick and chart, telling how much fluid to install for certain ambient temperatures. |

|

|

We took our Challenger on the road with the new transmission and immediately noticed how much crisper the gear engagement and shifts were. After warming everything up, we accelerated under part throttle and were impressed with the stall speed of the converter which seems to be nicely matched to the power range of the Hemi. |

|

We’ve already performed baseline drag testing and will need to break our new transmission in before bolting on some sticker tires and going to the dragstrip. With the current tires, traction would limit the benefits of our higher stall speed and firmer shifts. |

|

|

After a couple of weeks driving the car, we’re impressed with Gearstar’s improvements to the NAG1 automatic. The transmission shifts firmly, but not violently, and the heavy car responds nicely to the looser stall converter and modifications. Be sure to follow this project in future issues of Mopar Muscle as we further modify our Challenger and take it to the track for testing. |

Ready to experience top-notch transmission solutions and expert support?