For once, maybe we should cut the Blue Oval loyalist some slack. Sure, many of them would rather swallow their pride and bolt a venerable GM automatic behind their motors instead of taking their chances with a junk C6 or AOD, but who can blame them for exercising common sense? Even ego-stoking marques such as Ferrari, Bentley, Rolls Royce, and Jaguar have all relied on GM transmissions to reliably shuttle along their pretentiously ignorant clientele at some point in time.

The truth of the matter is that there are so many bulletproof GM trannies, it can be tough to choose the best unit for your application. Good problem to have, isn’t it? Within the GM’s camp of torque-transferring studs, there are proven dragstrip heroes such as the Powerglide, TH350, and TH400. Then there are cheap-and-easy early overdrives like the 700-R4 and 200-4R. Likewise, evolution is constant. The plethora of recently updated electronic overdrive units includes the 4L60, 4L65, 4L70, 4L80, and 4L85.

Naturally, this diverse lineup of all-stars requires doing your homework before investing in a performance transmission. Zack Farah of Gearstar is here to help with your studies. He’s been in the transmission business for nearly 30 years, and his hoards of happy customers are a testament to his innovative and exhaustive approach to rebuilding and testing GM automatics. In addition to helping you through the selection, we had Zack differentiate between various GM trannies, explain the basics of how they work, give tips on how to swap in an overdrive, walk you through the rebuild, and lend some tips on promoting parts longevity.

HISTORY

Gearstar owner Zack Farah got his start in the transmission industry 28 years ago at Tri Star International, a company that built over 100 transmissions and 300 torque converters every day. While the bulk of production at Tri Star was as an OEM supplier, high performance transmissions were Farah’s calling. "The high performance or racing transmission customer is building his pride and joy, and the demands placed on these machines are very different from those placed on passenger vehicles," he explains. Realizing that no company was offering anything other than off-the-shelf transmissions, Farah split from Tri Star and started Gearstar with the goal of manufacturing the finest performance automatic transmissions and converters available. "Each one of our transmissions is custom manufactured to a car’s specifications and application, taking into account horsepower and torque output, cam specs, rearend gear ratio, rear tire diameter, speedo type, vehicle weight, and vehicle use. Gearstar utilizes the most experienced technicians in the industry."

DON’T TRY THIS AT HOME

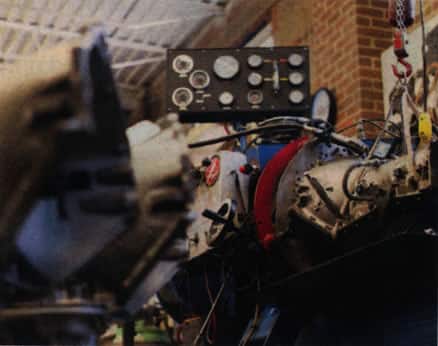

Due to the complex nature of automatic transmissions, few DIYers will ever attempt to tackle a rebuild. According to Farah, that’s not necessarily a bad thing. "A high performance transmission like the ones Gearstar manufactures simply cannot be built by DIYers". The master builders at Gearstar each have an average of 25-30 years experience. "Our builders have the latest diagnostic and testing equipment, which enables us to calibrate shift points, set redline, tune shift quality, check pressures and temperatures, and track down vibrations, noises, and leaks. Additionally, if one of our builders has a question, he can draw on the experience of other seasoned technicians. What Gearstar offers is unequalled in the industry, let alone something built in someone’s backyard."

ONE TRANS ONE BUILDER

"When Gearstar was first formed, we recruited the top five master builders out of a field of hundreds of technicians at Tri Star. All of these builders are experts in all automatics, but each one specializes in one specific type of unit. When you order a Gearstar transmission, it is assigned to the builder who specializes in that unit. That builder is responsible for that transmission from the time the order is taken, through the building process, and finally until the customer has installed the unit in his vehicle. His initials are inscribed into the case along with a tag number that matches the number on the invoice. The reason Gearstar uses the one-transmission, one-builder approach versus a more common assembly-line process is simple. By having one builder responsible for the transmission from start to finish, the customer is ensured a quality product. That builder knows that he is the one person responsible for that unit, which promotes pride in craftsmanship. It also makes it easy to track come-backs, which at Gearstar runs less than one percent. In our 28 years of experience, we’ve learned that the one-builder approach is the only way to guarantee a perfect transmission every time."

BIG HORSEPOWER COMPONENTS

Being that performance transmissions often fail at the 400-500 hp range, how can you possibly get them to survive at, say, twice that level? Farah explains that many of the key components for a transmission built to survive behind an 800hp motor are custom manufactured from 300M billet steel or aluminum. "These parts are also relieved to accommodate Torrington bearings instead of thrust washers to lower the inertia level inside the transmission, which transfers horsepower and torque more efficiently," he says, "This also helps lower drag to minimize heat and parasitic power loss."

DYNO TESTING

Dynos aren’t just for engines. Each transmission that Gearstar manufactures is extensively dyno-tested with a converter that is custom-manufactured and calibrated for that specific transmission. "Our dynamometer simulates the stress and drag that the transmission and converter package will experience in the customer’s vehicle," Farah explains. "We dyno-test the transmission and converter the equivalent of 60 miles on the street, in addition to running the transmission and converter at speeds of up to 130 mile per hour repeatedly. By dyno-testing each transmission, Gearstar is able to ensure that the package is perfect before it leaves our facility instead of using the customer’s car as a testbed. This ensures that the transmission has passed all noise, leak, vibration, and hydraulic pressure tests and shift timing and shift quality have been verified."

EASY OVERDRIVES

If you want drama-free interstate cruising without the hassles of a computer, your only two options are a 700-R4 or a 200-4R. There is much ongoing debate as to which is better, but both are extremely capable. While the 700-R4 is generally accepted as the stronger unit in stock trim, thanks to advances forged by the Turbo Buick scene, the 200-4R can survive in 8-second drag machines without a hitch. To help you decide, Farah points out some key differences between the two. "The 700-R4 has a deeper First gear ratio of 3.06:1, but that results in a bigger drop in rpm between First and Second, and it also has a taller overdrive," he says. It is slightly larger in size than the 200-4R, and Gearstar’s Level 4 big-block unit is rated to handle the torque of a stout 502. "The 200-4R has a taller 2.74:1 First gear ratio, so it doesn’t have that big drop between First and Second. It is slightly smaller in size than the 700-R4, can handle up to 800 lb-ft of torque, and uses less power to turn."

POWERGLIDE VS. TH350 VS. TH400

Unlike the Blue Oval camp, Gm has blessed Bow Ties with a slew of performance transmission options. So which one’s right for you? Although the venerable Powerglide can be built to handle 2,000 hp, it’s best suited for lightweight drag cars since it only has two speeds. To make decision-making simple, Farah recommends TH400s for big-blocks and TH350s for small-blocks."The Turbo 400 turbo is 50 percent stronger than the Turbo 350, but may use up to 25 percent more horsepower to turn," he explains. "The Turbo 350 can be manufactured to handle up to 850 hp, which is plenty stout for most small-blocks. The Turbo 400, and the other hand, can be built to handle up to 1,200 hp."

ELIMINATING SLIPPAGE

"Slippage is one of the most common types of transmission failure. Gearstar addresses this issue by machining the clutch drums to increase the clutch and steel surface area by as much as 80 percent. Since your clutch and steel surface area is a deceleration surface as well as an acceleration surface, we use a combination of the highest quality frictions materials on the market from Raybestos, Borg-Warber, and Alto Red Eagle. We also use hardened Kolene steels and custom manufactured extra-wide carbon fiber bands with Kevlar linings and billet anchors. All our transmissions have at least two shift kits along with extreme duty springs, sprags, and roller clutches. We custom machine our pumps and use billet stators to increase flow and maximize pressures."

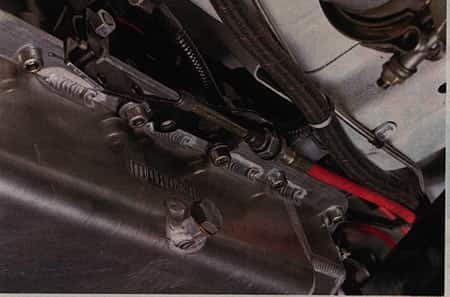

OVERDRIVE FITMENT

Swapping in a 700-R4 or a 200-4R trans yields an overdrive ratio in addition to a deeper First gear than a TH350 or TH400. However, some important fitment issues must be addressed. The most important modification hat must be performed is to correct the geometry at the throttle plate of the carburetor or TBI system, "These transmissions do not use a vacuum modulator to adjust line pressure and shift point rise like the Turbo 350 and 400," says Farah. "Instead, they utilize a TV (throttle valve) cable, which provides the transmission with a torque signal from the engine, so adjusting it properly is critical. The only other modifications required are simply relocating the crossmember and altering the driveshaft length. All the other components required for the transplant are provided with Gearstar’s transmission swap packages."

HOW AUTOMATICS WORK

Few things in hot rodding are as intimidating as a dissected automatic trans. The parts are many, and assembly requires specialized training, but understanding the role of each can help you make a more informed purchase. The primary components of an automatic are he pump, clutch drums, bands, and planetary gearset. The pump supplies hydraulic pressure to clutch packs, band servos, and valve body control systems. The clutch drums contain the clutch pack and apply piston, which transfers power to the planetary control element. The bands act as a brake clutch and hold elements stationary within the planetary gearset with pressure applied by the servo. "Perhaps the most complex component is the planetary gearset, which consists of a planetary carrier, a sun gear, and a ring gear," explains Farah, "All three gear elements mesh together, and each element can be individually held stationary. By also varying which element transmits input torque from the converter, the planetary set is able to vary gear ratios."

PRODUCT LINE

"Gearstar’s lineup of performance GM transmissions includes the TH250, TH400, 700-R4, 200-4R, 4L60. 4L70, 4L80, and 4L85. Although each is custom built to a customers needs, we offer several stages of strength to simplify selection. Our Level 1 units are completely remanufactured using improved Alto friction materials and a mild shift kit. They are capable of reliably handling up t 300 hp and are perfect for daily drivers. Our Level 2 transmissions are also remanufactured with all new internal parts. In addition, the torque capacity of the clutch packs is increased by more than 70 percent, and a more sophisticated shift kit is used. They’re rated at about 400 hp in a street-driven car. Gearstar’s Level 3 transmissions are equipped with all hardened and stress-relieved hard parts, including shafts, drums, and planetaries. Additional modifications include three different shift kits, expanded-capacity clutch drums with racing friction materials, and hardened Kollene steels. They’re rated at 500 hp in street/strip applications. Our Level 4 and 5 units are built to withstand the horsepower and torque of blower motors and high horsepower stroker small-blocks. These transmissions have all of the Level 3 modifications, and all hard parts are made from 300M billet steel or billet aluminum. They come blueprinted, and Level 5 units include a lifetime warranty.

COMPLETE TRANS SYSTEM

"When you call Gearstar for a new transmission, you are not getting an off-the shelf unit. We custom-manufacture your automatic transmission and converter to your exact requirements and engine specifications. Every Gearstar transmission and converter package is handled as a project. It is assigned to a specific builder who will coordinate with the technician manufacturing your converter to produce the perfect transmission and converter package. Gearstar will not sell a transmission without a converter. The reason for this is that the converter is an integral part of the transmission. They share the fluid and work in tandem as a torque-transferring system. How can anyone warranty a transmission without manufacturing the converter? Additionally, Gearstar has a standard 24-month warranty, which is one of the best in the industry.

SHIFT FIRMNESS

Firming up shifts can improve performance and sometimes trans life, but there is definitely a point of diminishing returns. In addition to lowering the comfort level for daily driving, too much shift firmness can result in excessive driveline shock and wear-and-tear. "Line pressure settings are basically a modified level of factory pressure rise," explains Farah. "Gearstar transmissions are internally modified to maximize line pressure through modifications made during the manufacturing process to the pump, pressure regulator, and valve body. On electronic transmissions, we make sure that all transmission programs are set to stock factory configuration. Otherwise you can over pressurize an electronic transmission, resulting in severe wear, damage, and eventually failure."

ALPHANUMERIC SOUP

In recent years GM has revised its transmission lineup. To avoid any confusion when selecting a trans for your street machine, here’s the difference between the 4L60, 4L65, 4L70, and 4L80. "The 4L60 is simply a revised version of the 700-R4 that fits behind LT-style blocks and utilizes a TV cable to control line pressure and shift points," explains Farah. "GM’s later computer-controlled version was dubbed the 4L60E, The 4L65 and 4L70, which fit LS motors, are upgraded versions of the 4L60E utilizing the latest generation planetaries for increased torque capacity. Finally, the 4L80E is essentially an electronically controlled TH400 with overdrive that is used in heavy-duty trucks from the factory."

COOLERS

All performance transmissions can benefit from a cooler, as heat is the number-one enemy of an automatic. Farah says that the cooler core should be mounted in front of the radiator, where it will receive direct airflow under all driving conditions. If that is not possible, then a cooler with an integrated fan can be mounted along the frame as long as it has direct airflow. "The capacity of the cooler should be as large as possible," advises Farah. "Unless you live in an extremely cold climate, we recommend at least a 20,000 GVW capacity cooler for our Level 1 and 2 packages. Our Level 3, 4, and 5 packages require a 30,000 GVW cooler due to the more aggressive driving conditions they will encounter. Optimal operating temperature for transmissions is 175 degrees F."

FLUID CHANGE

Since street/strip machines take far more abuse than a typically passenger car, their transmission fluid should be changed more frequently. "All of our transmissions are dyno-tested using synthetic trans fluid and are shipped with 7-9 quarts of the highest quality nonsynthetic fluid," explains Farah. "This synthetic blend provides the protection of a synthetic with the viscosity of a nonsynthetic. The transmission fluid does not need to be changed for 20,000 to 25,000 miles, at which point high-quality nonsynthetic fluid should be utilized. Automatic trans fluid has detergent qualities, which are harmful; to the friction material if overused."

Ready to experience top-notch transmission solutions and expert support?