|

1. Before the new transmission was slid between the ‘rails, Tim installed a TCI SFI-approved flexplate onto the snout of the crank using factory 14mm bolts. |

|

|

2. I bolted up a high-torque Powermaster starter to crank over the 9.5:1 compression ratio engine. The infini-clock feature of this starter enabled me to move the solenoid away from the header with just a twist of a couple screws. |

|

3. Today’s automatic overdrive transmissions offer gear ratio spreads that are perfect for a truck that will see more time on the highway than the dragstrip. Gearstar specializes in building hi-po versions of these trannys that will stand up to anything I plan on dishing out through motor mods. The factory 4i65-E designation (4=four-speed, L=rear-wheel-drive, 65=torque capacity, E=electronic) goes right out the window after Gearstar gets its hands on the trans. This level 4 tranny will take full throttle blasts from a dead stop and not break even with more than 600 lb.-ft running through the 10-inch 2,600-rpm stall converter. Out on the highway, cruising economy will be enhanced thanks to 3.06 First gear ratios, and a lockup converter that will give the trans a 1:1 ratio after 50 mph. |

|

|

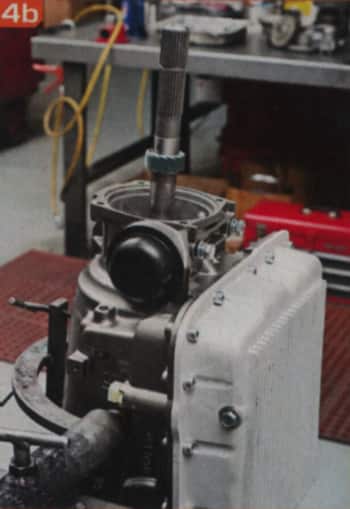

4. Gearstar beefs up the GM design with a 300M hardened-steel input shaft that won’t twist, ALTO Redline Racing bands that are 20-percent wider than stock and made from carbon-fiber, which resists slippage, a high load sprag, a 13-vqne pump, extreme-duty springs, and a Corvette servo. At Gearstar, one technician assembles each tranny and then it’s dyno-tested before it ships out to the customer. What’s this all mean on the street? My truck barks Second gear like I’m kickin’ the family dog and I can keep on throwing power at this tranny and it won’t break. |

|

|

|

5. The other component in the BRP swap kit is this tubular transmission crossmember. The 4L65-E transmission is 3-inches longer than my old TH400, so a new set of mounting holes had to be drilled into the framerails. I drilled the new holes using a right-angle drill from Snap-On. |

|

|

6. The new crossmember provides extra clearance for exhaust pipe routing and works with aftermarket and factory trans mounts. |

|

7. A factory trans dipstick would need a fairly radical bend put into it to be accessible, so I installed one of Lokar’s custom ones. The O-ring seal was enhanced with silicone sealant before the dipstick tube was bolted to the firewall. |

|

|

8. Heat is what kills transmissions so it’s paramount that we make every effort to keep the trans fluid temperature in check. To that end, I installed a Hayden trans cooler on the core support, just ahead of the radiator. The cooler is plumbed directly into the transmission and electric fan pulls heat from the fins of the cooler. |

|

9. Perhaps the coolest benefit of a modern computer-controlled trans is how much control you have over its performance. This Compushift standalone trans computer can either be pre-programmed with your truck’s tire diameter, gear ratio, and intended use to work right out of the box, or you can add a remote display to customize the trans yourself. |

|

|

10. In a carbureted application such as mine, a throttle position sensor must be added to the carb linkage to tell the computer how hard you’re on the go-pedal, which determines how quickly it will shift the trans. |

|

11. The rest of the trans install is pretty straightforward, The computer and harness are hidden out of sight and away from extreme heat sources. |

|

|

12. Aside from the power, ground, and tachometer wires, the harness plugs right into the transmission and TPS. Remarkably, our stock driveline fit right in place thanks to the forward placement of the new engine and the longer length of the new transmission. |

Ready to experience top-notch transmission solutions and expert support?