Operating on the theory that a chain is only as strong as its weakest link, the driveline components of the 2010 AMSOIL/STREET RODDER Road Tour roadster pickup have been selected carefully to make sure they can all take the power our potent small-block Ford can deliver mile after mile – there will be no weak links in our drivechain.

For a bulletproof transmission we turned to Gearstar Performance Transmissions for their experience and reputation. Zack Farah, Gearstar’s owner, got his start over 25 years ago at Tristar International where they were manufacturing upwards of 100 transmissions and 300 converters each day, but it was the racing and high-performance market that gave him the most satisfaction. “The high-performance or racing transmission customer is building his pride and joy,” Farah explains. “The demands placed on these machines are a lot different from those placed on the family car.” Gearstar’s goal s to build the best high-performance transmissions specialized to the individual needs of the most discerning customers. To maintain consistency and quality during the building process, only the best components are used and a single technician handles each transmission.

When selecting a contemporary Ford transmission for a street rod there are two categories to choose from: the three-speeds, which include the c4, produced since 1964, and the C6, produced since 1966; and the four-speed overdrives, the AOD produced since 1980, and E4OD produced since 1989. The C4 and C6 transmissions were known in the ‘60s and ‘70s as dependable transmissions that could be modified for Ford powered cards used on the strip as well as the street. And thanks to better technology, advanced bands and clutches, improved shift kits, and the availability of super hard internal parts, Gearstar can provide any of them custom built for you application.

Today most street rodders who opt for an automatic choose an overdrive and ford has a great one in the AOD. Ford beat GM to the showrooms with an automatic overdrive transmission by a year, the new AOD contained basic design elements of the C4 and cast-iron FMX, highly modified and conjoined. Designed to mate up to the 5.0L/302ci engines, the AOD can be easily adapted to the Ford Y-Block and the FE series engines, and thanks to high-performance parts and modifications by Gearstar they can meet the demand for a dependable, efficient, high-performance overdrive transmission for the true Ford believers.

Over the next few years Ford redesigned many internal components to meet increasing demands upon their AOD transmission and in 1992 the AOD became the AOD-E, the E denoted it was an electronically controlled transmission. Since Ford has continued to refine components in the AOD-E, and many of these updated components will retrofit to the AOD line. Combine the latest generation Ford factory components with those available from the aftermarket (shift kits, clutches, bands, shafts, drums, and torque converters) and Gearstar has everything to build the perfect AOD or AOD-E.

PARTS ARE PARTS

While automotive transmissions may have two, three, four, or more gears, computer controls, and a variety of bells and whistles, the basic internal parts remain the same, there are just more of them in some than others. Let’s take a look at the major components and some of the usual performance upgrades:

TORQUE CONVERTERS

This is what connects the engine to the transmission. Not only does it allow the engine to keep running while the car is stationary, but it can also provide torque multiplication when accelerating form a standstill. For a simplistic explanation of how at torque converter works, picture what would happen it two electric fans were facing each other and one was turned on. As the one under power began to turn and move air, the other one would also begin to turn. If you can visualize that, you’ve got the basic idea of how a torque converter works. In a torque converter, both fans are in a container: one is connected to the engine and the other to the transmission, and oil is used rather than air.

As might be expected, there is some slippage inherent with a torque converter, so many overdrive automatics now have converters with a hydraulically applied internal clutch that hooks the transmission directly to the engine for increased efficiency. While better fuel mileage is often considered to be the advantage of a lockup converter, there is another, often overlooked, purpose. The higher ratio provided by an overdrive fourth gear can put an additional load on a conventional converter, causing excessive slippage even in light-throttle cruise conditions. The slippage creates heat and heat’s the enemy of the transmission. When used with an overdrive automatic a lockup style will lower engine speed in cruise conditions and lengthen the transmissions life. Overdrive automatics and lockup converters are made for one another.

PLANETARY GEARS

As gears go, planetaries can do it all. Made up of three elements-a sun, ring, and planet pinion gears- they can provide forward or reverse rotation, a speed increase, constant speed, or a speed reduction. Three things are necessary to make planetary gears operate: an input (power from the engine), output (power going out), and a reactor (one of the elements is held stationary). The gear ratio and the direction of travel depend on which element is performing each function. Most transmissions have more than one planetary gear set to provide a variety of gear ratios.

BANDS and CLUTCHES

Bands and clutches hold the reactors stationary. An automatic transmission goes into gear by holding one part of a planetary gear set stationary with a band or a clutch that is applied by hydraulic pressure. One reactor is released and another applied when the transmission is in neutral if no reactor is applied. If you’ve ever been in a car and the transmission felt like it was slipping, that’s exactly what was happening-the band or clutch pack wasn’t’ holding the reactor stationary and it was slipping and not transferring full power. In an extreme case, the clutches, or band, don’t hold at all, and one or more gears (and in some cases, every gear) stops working as a result.

VALVE BODY

The valve body is the hydraulic “brain” of the transmission. It controls the shifting of gears by controlling which reactor is applied when. Some transmissions use hydraulic pressure from a governor, throttle valve, or vacuum modulator to determine shift points, while many contemporary versions use computer-controlled electromechanical servos.

TRANSMISSIONS MODIFICATIONS

Let’s start with the torque converter. In many cases, the stall speed of the converter is increased. Simply put, stall speed is the rpm that the engine will reach with the transmission in gear, the breaks applied, and the throttle held wide open. The higher rpm simply allows the engine to produce more power, which will launch the car harder from a standstill. The downside is the higher stall speed converters will slip more in “normal” use. That can create excessive heat, which is what damages transmissions. Of course the perfect solution is a lockup converter with increased stall speed – that’s the best of both worlds.

SHIFT KITS

Most stock automatics are designed to be seamless; that is the shifts are smooth to the point of being hard to detect. This is done by timing the release and application of the various reactors. One may begin to apply as the other begins to release so there is a split second of overlap. While this results in a smooth shift, there is a certain amount of slippage that takes place in the process, which wears the friction surfaces.

Shift kits generally do two things: They change the timing of the release and application of the reactors, which results in a firmer, more noticeable shift and may also lengthen the life of the transmission. In addition the hydraulic pressure to apply the reactors is often increased, which means the clutches and bands have more holding power, thus increasing the torque capacity of the transmission.

With many transmissions today using computer controls, a variation on the shift kit theme is the hopped-up computer. It can and will do the same thing as a conventional shift kit, but changes can often be made without dropping the trans pan.

FRICTION SURFACES

A common method to increase an automatic transmission’s torque –carrying capacity is to improve the friction surfaces that hold the reactors. This may be done by using improved materials, more clutch plates, wider bands, or a combination of them all.

HARD PARTS

Just as with a manual transmission, an automatic has mechanical components that are susceptible to damage when overstressed. As the horsepower applied to it is increase, it is often necessary to increase the strength of an automatic transmission’s shafts, clutch drums, planetary gear sets, sprags, and other internal parts.

COOLERS

According to Farah, all performance transmissions can benefit from a cooler, as heat is the number one enemy of an automatic. The cooler core should be mounted in front of the radiator, where it will receive direct airflow under all driving conditions. “If that is not possible then a cooler with and integrated fan can be mounted along the frame as long as it has direct airflow. We recommend at least 20,000 GVW capacity cooler for our level 1 and 2 packages. Our level 3, 4, and 5 packages require a 30,000 GVW cooler due to the more aggressive driving conditions they will encounter.” Farah adds that “optimal operating temperature for transmissions is 175° F.”

AN OVERDRIVE FOR THE ROAD TOUR

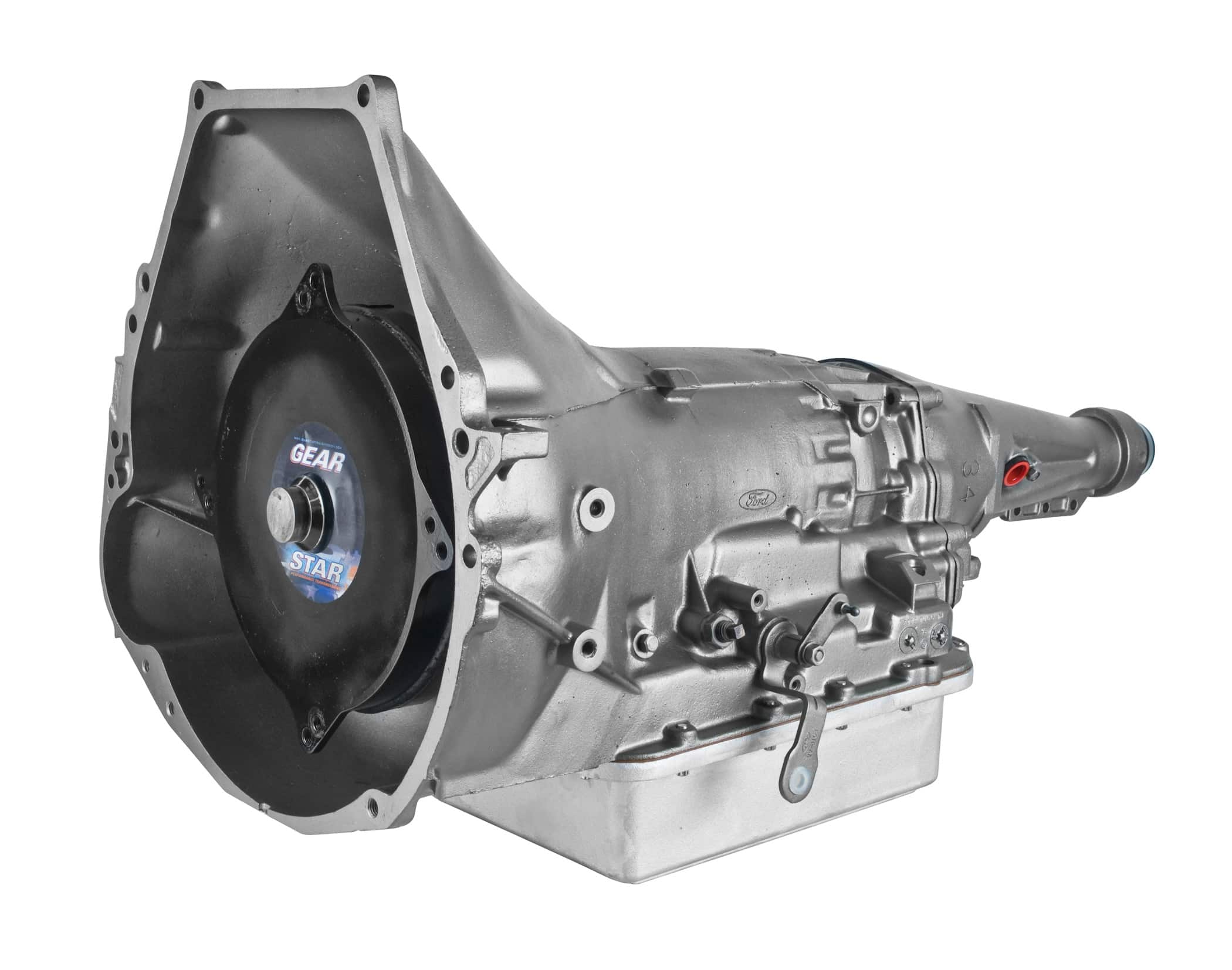

For this year’s car we chose Gearstar Performance Transmissions’ Ford AOD Level IV automatic overdrive transmission with a custom 10-inch, non-damper-style, billet converter with stall speed tailored to the engine’s specs.

Based on a stock AOD two-wheel drive short shaft transmission, the first step to Level IV performance begins with qualifying the case, high-pressure washing bead blasting. Then the case is rewashed and re-inspected before it moves to be painted. After the case is painted, the internal components are cleaned and thoroughly inspected before a technician gets to work on the custom remanufacturing process.

Reassembly starts with a master overhaul kit with Kolene steels and Raybestos racing frictions. Two valve body reprogramming kits improve shift timing and quality and a high-rpm governor assembly allows for max throttle up-shifts at the maximum engine speed. A complete bushing kit, new Torrington bearings, and new thrust washers are installed. The original equipment clutch drums are modified to accept expanded capacity clutch packs, thus increasing the torque capacity of the transmission.

An extremely critical component is the reverse input drum. Its main function is to provide a friction element by incorporating a oneway roller clutch for second gear and a friction surface for the fourth overdrive band.

Gearstar replaces this drum with the latest generation diode clutch drum, which is superior to the OE seven-roller design, This wider drum allows for a fourth gear band that 30 percent wider and is made of a sturdy carbon-fiber material designed to tolerate higher heat and more extreme conditions rather than the original equipment paper lining. Further, the earlier cast-iron input drum is replaced with the late-model stamped steel input drum/shaft, the direct clutch drum is also replaced with the late stamped steel design, which provides a higher-capacity clutch pack, the OE direct clutch third shaft is updated with a 300M billet shaft, which eliminates any breakage concerns. A new Kevlar low-reverse band design to tolerate higher heat and better friction coefficiency is used and the standard second gear, three-disc clutch pack design is updated to a higher capacity four-disc design and a lightweight, high-performance driveshell reducing internal rotating mass. An expanded capacity billet overdrive racing servo and updated servo apply pin, which engages the overdrive band, are also used. In short, every weak point in these transmissions is addressed to provide years and miles of trouble-free service.

Finally, because of the many various linkage configurations available from Ford, Gearstar Performance uses a Lokar 360° adjustable shift linkage assembly. Lokar also provides the throttle pressure signal delivery cable system and an extra capacity cast aluminum pan is part of the package, although other parts, such as chrome and polished aluminum, are available upon request.

CONTROLS

Gear changes will be handled by a Lokar shifter, which also mounts one of their parking brake assemblies. The throttle valve cable, dipstick, and tube are also from Lokar.

|

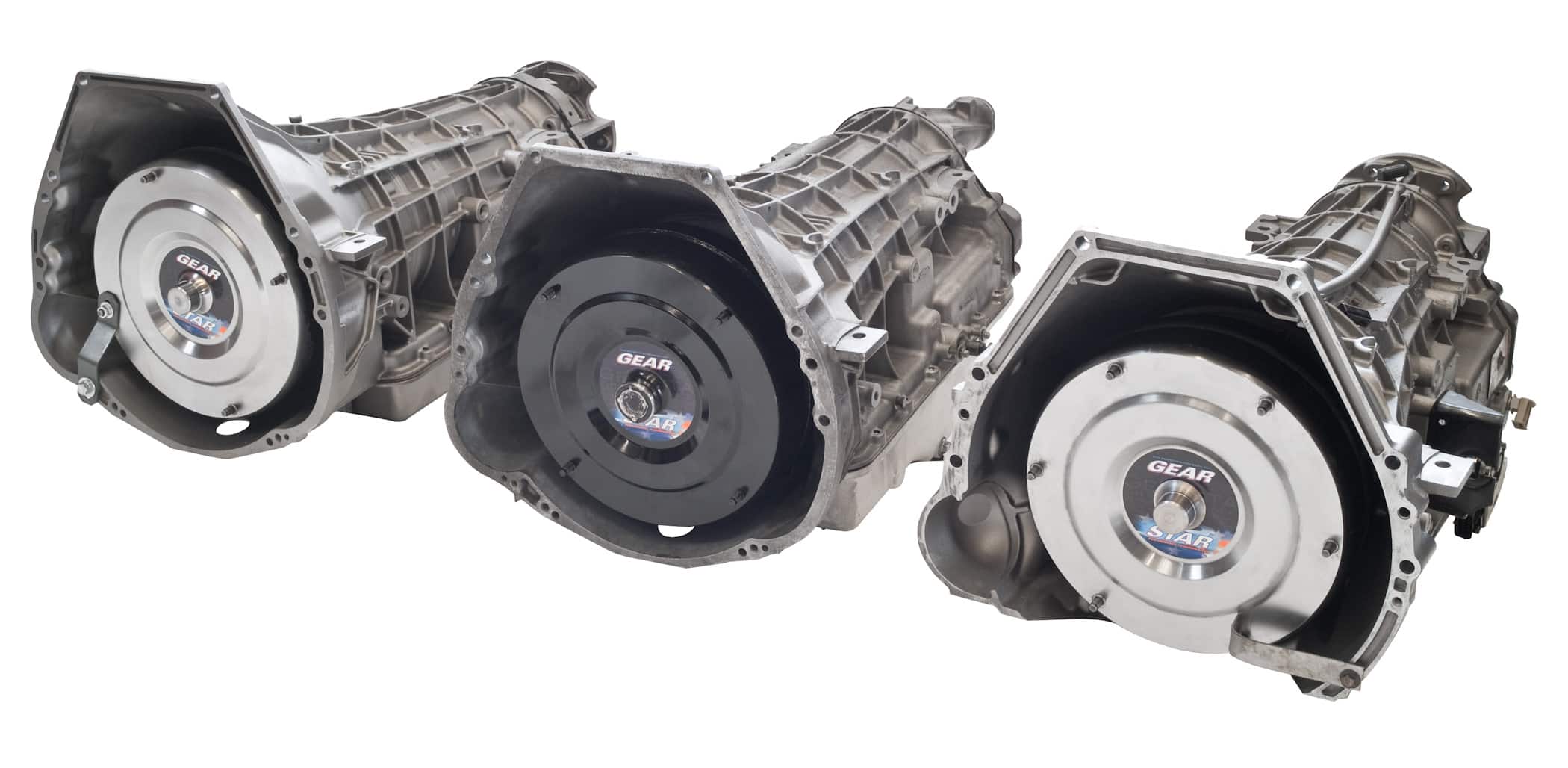

Ford was first to offer an overdrive automatic transmission with the introduction of the AOD in 1980 and we’re using one in the 2010 AMSOIL/STREET RODDER Road Tour roadster pickup. One of the advantages to the design is that no computer or electric converter lockup control is necessary and with a host of improvements Gearstar provides it will easily handle the power our Smeding small-block will deliver. |

| For those building a Ford-powered street rod that requires an overdrive automatic with the utmost in big-block torque and horsepower capacity, look no further than Gearstar’s line up of E40D transmissions. Note the tall bellhousing pattern that big-blocks require. |  |

|

One of the best buys around and perfect for street rods with stock Ford engines –Gearstar offers a rebuilt AOD with a host of internal enhancements for $1,595. |

| For high-horsepower Ford small-blocks, Gearstar offers their Level 3 AOD; for really wicked small-blocks as well as some big-block applications, Gearstar offers their custom-built Level 4 option. While they may all look the same outside, internally there are significant differences. |  |

|

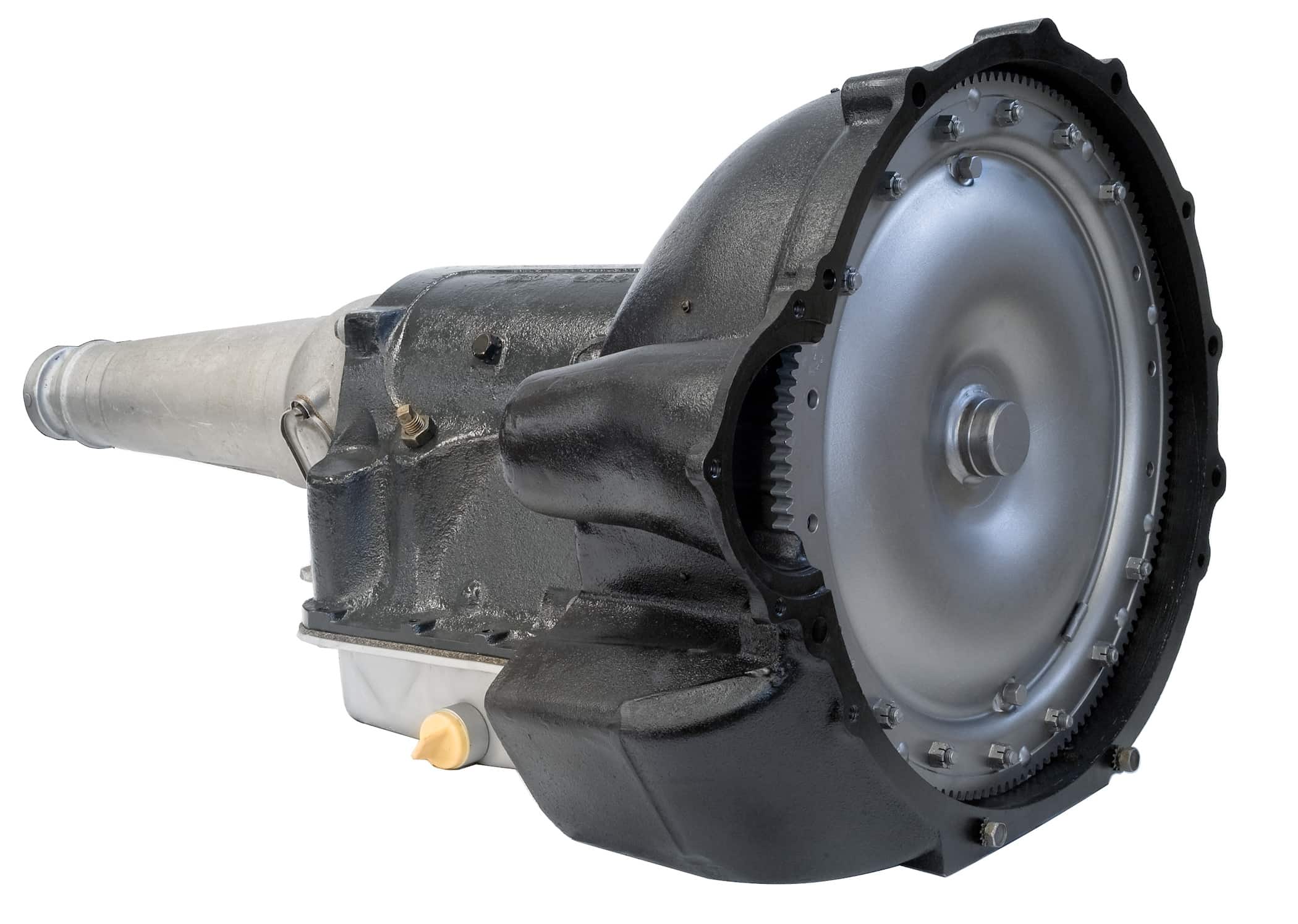

When it comes to heavy-duty three-speed automatics, the Ford C6 is legendary. Gearstar offers them in Level 3 and 4 configurations. |

| The C6 is a big heavy transmission. Note the bellhousing shape that fits the 351M/400 and 429/460 blocks. |  |

|

When it comes to automatic transmissions, few have been around as long as Ford’s cast-iron Cruise-O0Matic. Introduced in 1958, it morphed into the FMX in 1968 and remained in production until 1980. Note the air inlet on the bellhousing. |

| While Gearstar specializes in the latest in transmission technology, they can handle many vintage transmissions, like this Cruise-O-Matic. Note the bolt-together torque converter and the bulge in the case-it’s a vent-these transmissions were air cooled. |  |

| One of the reasons Gearstar can provide virtually any transmission is their large supply o re-buildable cores. | |

| This is how a Gearstar transmission is shipped. It comes in a crate, fully tested with the fluid only needing to be topped off. |  |

|

The Gearstar 10-inch lockup converter provides the best of both worlds – increased stall speed for improved off-the-line performance and the full lockup feature for increased mileage on the highway. |

Ready to experience top-notch transmission solutions and expert support?