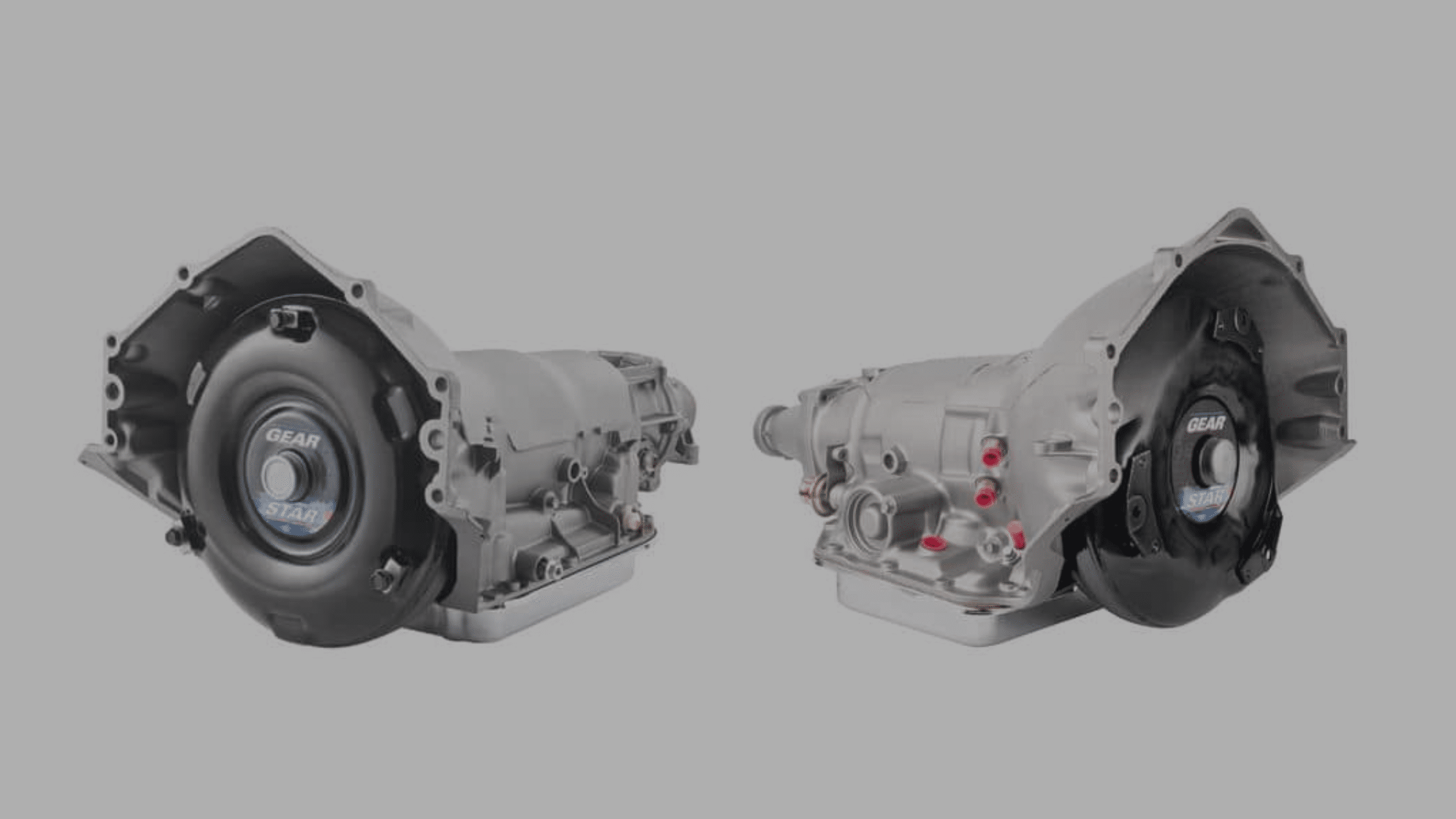

The TH350 and TH400 are both iconic automatic transmissions built by General Motors, but they cater to different needs. The TH350 is lighter and more initially suited for street performance with moderate horsepower, while the TH400 is heavier, more robust, and ideal for heavy-duty applications, particularly those involving big blocks. Choosing between them depends on your vehicle’s power and intended use.

Torn between the Turbo-Hydramatic 350 and 400 transmissions? Let’s take a closer look and spot the differences.

The TH350 is lighter, smaller, and can be modified with aftermarket parts to match the TH400’s performance for racing at a lower build size, making it a versatile choice for high-performance builds that would benefit from the lower weight.

The TH400, however, is better suited for heavy-duty tasks requiring more torque, like in heavier trucks, and was even built into a suite of high-end, high-performance vehicles, including Rolls-Royce and Jaguars. Here’s what to keep in mind when choosing between the two.

Overview: TH350 vs. TH400 Transmission

The TH400 is a three-speed automatic transmission built to replace General Motors’ two-speed Powerglide transmissions. It was built into high-torque, high-horsepower cars from GM’s lineup.

The TH350 was released a few years later, as a lightweight version designed for lower torque applications.

The TH400 is constructed of an aluminum and cast-iron body, built into a bell housing. The TH350 is cast out of pure aluminum, making it significantly lighter, at the cost of handling less torque and horsepower right out of the gate. The performance of both transmissions is significantly influenced by the design and robustness of the clutch packs, which include multiple clutches interacting with steel plates to manage friction and efficiency.

While the TH400 features a 32-spline driveshaft, the TH350 is equipped with a smaller 27-spline driveshaft. Stock TH400s can handle well over 400 horsepower and be tweaked for up to a thousand – meanwhile, the stock TH350 was built for cars around 300-400 horsepower. Adjusting the line pressure in these transmissions, especially in high-torque applications, can reduce clutch slippage and enhance reliability under increased power demands.

Both the TH400 and TH350 transmissions were built with multiple different specifications over the years. Vintage car enthusiasts tend to keep an eye out for TH400s with a built-in variable pitch stator torque converter called a Switch-Pitch. Meanwhile, the later TH350s released between 1979 and 1984 featured a lock-up torque converter, while versions produced after 1984 were built with an electronic torque converter for better fuel economy. The valve body in these transmissions plays a crucial role in determining shift firmness and speed, with various options available for both factory and aftermarket modifications.

A Brief Look at the Hydramatic Series

The Hydramatic transmission was first introduced in 1939 by Oldsmobile, a division of GM, marking the first mass-produced automatic transmission in the world, a legendary milestone in automobile history.

This initial version featured a four-speed, dual-range design, which allowed drivers to enjoy a smoother ride and more effortless driving experience compared to manual transmissions. During World War II, the Hydramatic transmission was even adapted for use in military vehicles, which further accelerated the development of stronger, more reliable, and more complicated automatic transmissions.

In the post-war years, the Hydramatic continued to evolve. The Turbo Hydramatic series, introduced in the 1960s, represents a significant leap in the Hydramatic’s evolution and effectively supplanted the original Hydramatic transmissions, as well as the Dynaflow and Powerglide series.

The TH400, introduced in 1964, was designed for high-torque applications and became known for its strength and reliability, making it a favorite in heavy-duty trucks and performance vehicles. The TH350, introduced in 1969, offered a lighter alternative with a balance of performance and durability, making it popular in smaller cars and racing applications.

A key factor in the evolution of the Hydramatic series was the development of different valve bodies. Not all valve bodies are the same, and aftermarket options can significantly impact the shift firmness and speed, especially in heavy-duty or performance racing applications.

Both transmissions were eventually phased out when fuel efficiency demands became too great for these older builds to handle. However, they remain the hallmark of almost any high-horsepower American car built in the 60s, 70s, and 80s, and are still sought after and rebuilt by high-performance transmission manufacturers such as Gearstar.

Power, Torque, and Gear Ratios Capabilities

The TH400 is the stronger transmission. It’s built heavier and larger than the TH350, with heavy-duty applications in mind. Even later versions of the TH400 continued to focus on handling high-torque, high-horsepower input.

A stock TH400 can handle 450 ft-lbs of torque, whereas the TH350 is designed for about 410 ft-lbs of torque. TH400s have a much higher upper limit of horsepower, especially when appropriately modified. The TH350, however, may still be better for overall performance when taking aftermarket modifications into account, because it can handle enough while boasting a shorter and lighter build, and gear ratios slightly favoring initial acceleration in first gear.

In drag racing scenarios, engine rpm plays a crucial role in optimizing vehicle launches. Features in transmissions like trans brakes and manual valve bodies allow drivers to manipulate engine rpm for maximum power delivery at launch, enhancing the performance of both the TH350 and TH400. While some features might seem like a big deal, such as the inclusion of a lock-up converter, they may not significantly impact overall performance and are often minor considerations in the grand scheme of vehicle setup.

Weight and Performance: Why It Matters

Drag racers and performance enthusiasts will want to opt for the lighter transmission that can handle just about anything you’re likely to install in a race car, provided you’ve got a good torque converter to match your needs.

The TH350 at stock is nearly 20lbs lighter than the TH400 while dry, and a good deal lighter when filled due to the difference in volume between the two transmissions, which means you’re dealing with far less rotational mass – that’s a huge difference in drag racing. It’s also about three inches shorter in total length, from the output shaft to the end of the bell housing.

Rebuilding, Shift Kits, and Longevity Considerations

Both the TH350 and the TH400 are well-loved and well-known, and if you have a used TH350 or TH400 in good shape, you’re likely to find transmission rebuilders who are more than happy to restore the transmission for a good price.

Due to its robust build, however, the TH400 is particularly well-known for its intense longevity. In good condition, it can withstand well over 200,000 miles, even when put through its paces with big-block engines.

Suitability for Daily Driving vs. Heavy-Duty Use and Drag Racing

While the TH400 is durable, it’s overkill for daily driving. If you don’t need something built to lug immense weight around, then the TH350 will prove to be a more fuel-efficient and effective automatic transmission with plenty of power and enough performance for nearly any application, from casual street driving to high-performance racing. The TH350 is particularly suitable for a street car, offering a balance between everyday usability and performance.

If you’re in the market for something ready to handle up to 1000 horsepower with proper modifications in a classic car, then a custom TH400 may be more your speed.

Conclusion

Choosing between the TH350 and TH400 comes down to your specific needs. The TH350 is ideal for lighter vehicles and racing applications, offering versatility with its smaller size and lower weight. On the other hand, the TH400 is built for heavy-duty use, handling higher torque and power with ease, making it perfect for larger trucks and high-performance builds.