What is an aftermarket torque converter? The torque converter is a vital component of many auto transmission vehicles. It plays a crucial role in starting a vehicle and takes the part of the conventional clutch by readily connecting – and separating – the transmission and engine.

It is the seamless interaction between the torque converter, the hydraulic energy (generated by special fluid), and the engine (with its mechanical kinetic energy) that powers the transmission for automatic driving.

In other words, a torque converter efficiently transfers rotating power from a prime mover right to a rotating driven load. It is the latter that helps in connecting the power source to the load within an automatic transmission.

Therefore, in simple words, the torque converter functions primarily as a mechanical clutch in manual transmission vehicles.

The torque converter is set between the engine flexplate and the transmission. It is responsible for enabling engines to run while the vehicle is stationary. But as soon as the vehicle starts moving, the torque converter transmits power hydraulically via the transmission fluid.

An aftermarket torque converter is a spare part designed to work like the factory-fitted torque converter. Many specialists consider aftermarket torque converters the best option whenever there is a need to replace the defective factory-fitted torque converter.

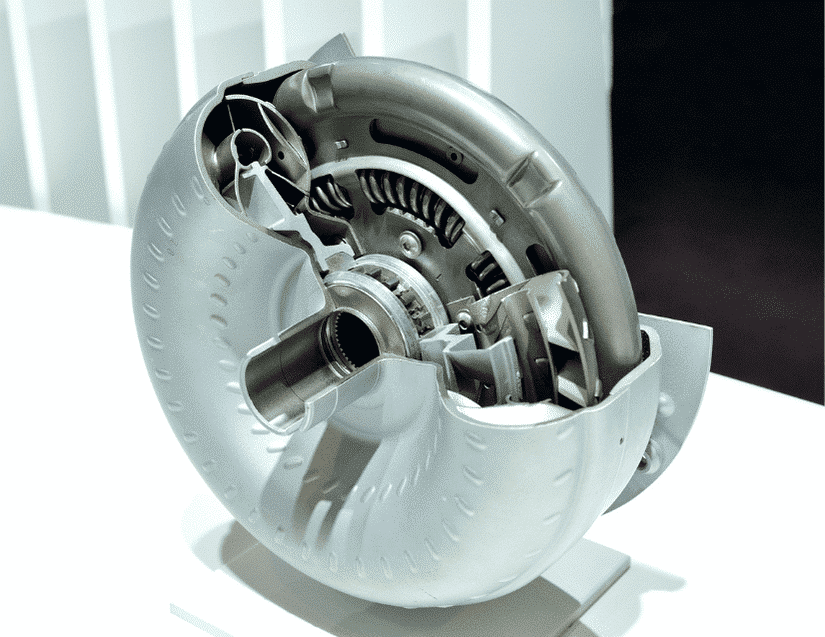

The major components of a torque converter include:

- Brake lining

- Stator

- Turbine wheel

- Torsional damper

- Impeller

- Lock-up clutch, etc.

How Does a Torque Converter Work?

To understand how a torque converter works, highlighting the 3 stages of operation it undergoes is essential. The 3 stages – i.e., stall, acceleration, coupling – are discussed separately.

Stall

This refers to a situation in which the turbine can no longer rotate, despite the application of power – by the prime mover – to the impeller. Moreover, the application of enough input power assists the torque converter to generate maximum torque multiplication. The ensuing multiplication is known as the ‘stall ratio.’

The ‘stall’ stage of the torque converter’s operation lasts briefly, especially when the load starts moving initially because there will be a considerable difference between the turbine speed and pump.

Coupling

Coupling gives rise to fuel economy when the lock-up clutch is applied. This is the point at which the turbine achieves up to 90 percent of the impeller’s (an internal component of the torque converter) speed.

At this point, one can liken the operation of the torque converter to that of a simple fluid coupling since torque is no more apparent.

Acceleration

A situation where the load accelerates, but there is a significant difference between the turbine speed, and impeller causes the torque converter to produce torque multiplication that is far lesser than what is available under stall conditions.

However, what determines the amount of multiplication generated is the real difference between the turbine speed and the pump.

What are the Internal Components of a Torque Converter?

The torque converter has 3 major internal components that, without them, the unit cannot operate effectively.

The internal components are the stator, turbine, and pump. Another vital component is the transmission fluid that works by moving through these significant internal components.

Let’s take a closer – but brief – look at each of these significant internal components of a torque converter:

Stator

Stators can be found right in the middle of torque converters. Its primary duty is to redirect the transmission fluid just before it gets into the pump again.

The stator comes with an internal one-way clutch that enables it to freewheel at specific operating speeds. Nevertheless, this internal component is situated on a fixed shaft.

Turbine

The output shaft connects the turbine to the transmission. When the turbine spins, its operation causes the transmission to set the vehicle in motion. As soon as the transmission fluid exits the turbine, the latter moves opposite to that of the pump and the engine.

Pump

A torque converter’s housing is connected to the engine’s flywheel while, on the contrary, the fins of the pump link to the housing. The pump spins and then pushes the fluid in an outward motion, operating like a centrifugal pump.

When the pump operates, it helps in creating a vacuum that conveniently attracts even more transmission fluid toward the torque’s center, and then it enters the turbine straightaway.

What Sets an Aftermarket Torque Converter Apart?

An aftermarket torque converter has several benefits that many other spare parts don’t bring to the table.

Two notable benefits of aftermarket torque converters are:

Slippage

A few aftermarket torque converters come equipped with what is referred to as a ‘lockup’ contraption. The primary job of this mechanism is to readily bind the vehicle engine to the transmission in a rigid manner when their speeds are nearly equivalent.

This is the operation that prevents loss of efficiency and incredibly high levels of slippage.

The lockup mechanism’s action also helps to significantly boost fuel efficiency – even up to 65 percent – while simultaneously eliminating wasted power.

However, uninterrupted high levels of slippage could make it somewhat tricky for the torque converter to readily disperse heat.

When a torque converter cannot dissipate heat, it damages the elastomer seals. These seals are primarily responsible for retaining or sustaining fluid within the torque converter.

Over time, the fluid within the torque converter starts leaking, and when there is no more fluid within it, the machine stops working altogether.

Torque multiplication

A regular fluid coupling and an aftermarket torque converter do not perform the same way. The former’s primary responsibility involves matching the rotational speed but cannot multiply torque.

On the other hand, an aftermarket torque converter quickly multiplies torque, especially in situations in which output rotational speed is meager. In such cases, fluid from the turbine’s curved vanes deflects off the stator.

Furthermore, fluid deflection can only occur when the stator is temporarily locked against its one-way clutch. This results in something equivalent to a reduction gear.

Torque multiplication can also come about when there is a significant difference between both input and output speeds.

Conclusion

If the torque converter in your vehicle fails, the vehicle transmission will suffer from it. Faulty torque converters lead to loss of power and can even cause transmission gears to slip unceremoniously because of a reduction in the seamless flow of the transmission fluid.

Using an aftermarket torque converter has several benefits, thanks to the operation of some components like the stator, impeller, turbine, etc. This is why the aftermarket torque converter is the perfect option if you need to replace your vehicle’s faulty, factory-fitted torque converter.

Ready to experience top-notch transmission solutions and expert support?