The world of high-performance automotive engineering is a realm where speed and precision reign supreme. Whether you’re on the racetrack or pushing your limits on the open road, the ability to shift gears swiftly and smoothly is paramount. In this 3000-word article, we will embark on a fascinating journey into the science behind lightning-fast shifts and explore the high-performance transmission technology that makes it all possible.

I. The Basics of Transmission

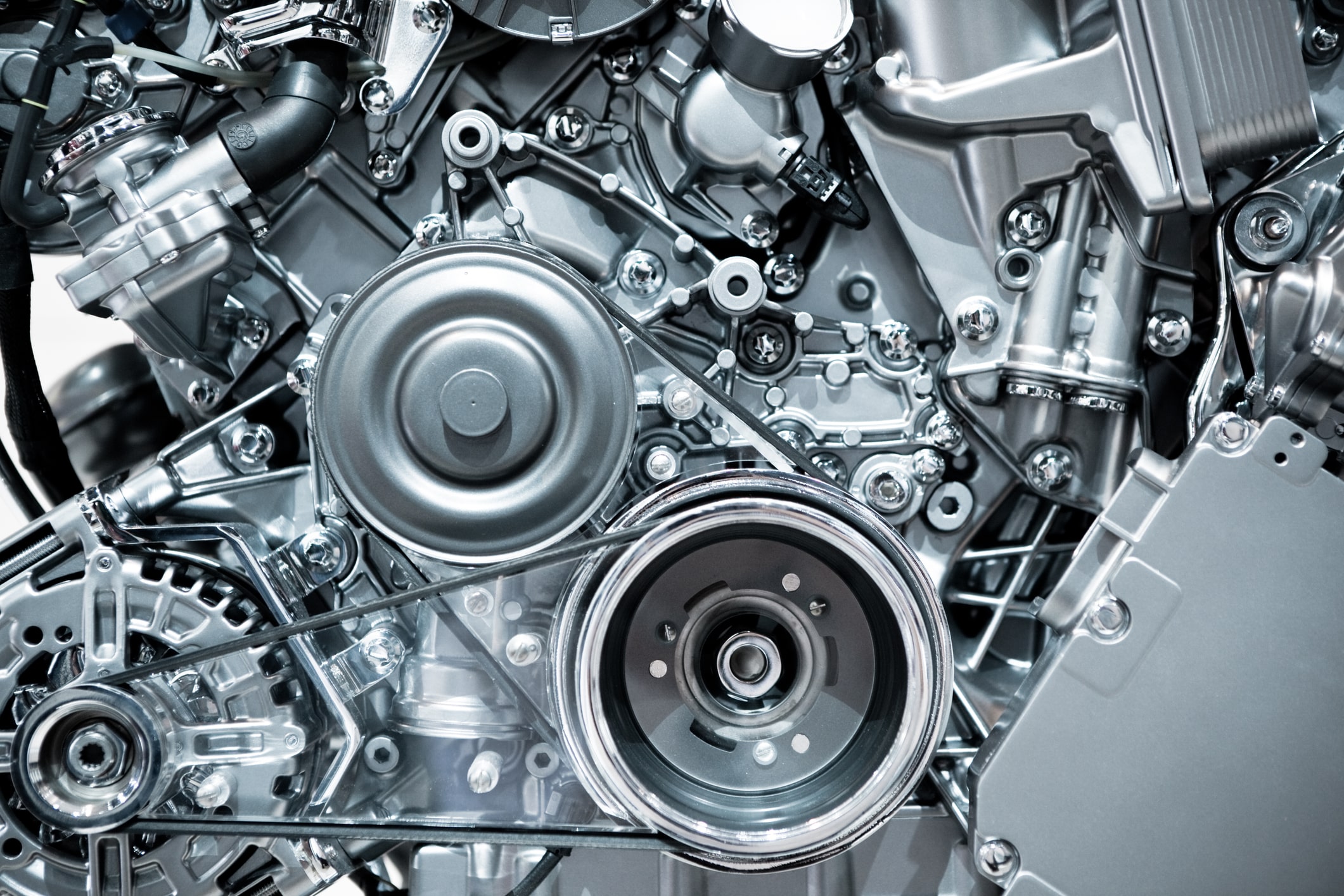

Before delving into the intricacies of high-performance transmission technology, let’s establish a solid foundation by understanding the fundamental workings of transmissions. At its core, a transmission is a mechanical device responsible for transferring power from the engine to the wheels. We will briefly touch upon the following key points:

Gear Ratios (100 words): Gear ratios are the key to translating engine power into motion. Lower gears provide more torque and are used for acceleration, while higher gears offer more speed and efficiency. High-performance transmissions often feature unique gear ratios that cater to the specific powerband and performance goals of the vehicle, allowing for optimal acceleration and top-end speed.

Manual vs. Automatic (100 words): The choice between manual and automatic transmissions is crucial in the world of high-performance vehicles. Manuals offer direct control but demand skill and precision from the driver. Automatics, on the other hand, have evolved significantly with the advent of advanced electronic controls, making them competitive and sometimes superior in delivering lightning-fast shifts, especially in modern high-performance cars.

Clutches (100 words): In manual transmissions, clutches play a vital role in engaging and disengaging gears. High-performance variants often employ specialized clutch materials, such as carbon or ceramic, to withstand the increased torque and heat generated during aggressive driving. These upgraded clutches provide better grip and durability, crucial for lightning-fast shifts without slippage.

Synchromesh (100 words): Synchromesh technology is critical in manual transmissions to ensure smooth gear changes. It equalizes the speed of the gears being engaged, preventing grinding or harsh shifts. High-performance transmissions often incorporate advanced synchromesh designs that reduce shift time, enhancing the driver’s ability to execute quick and precise gear changes under extreme conditions.

II. The Need for Speed

High-performance transmissions are designed with one primary goal in mind: maximizing speed. Whether you’re accelerating from a standstill or shifting gears at high RPMs on the racetrack, every millisecond counts. In this section, we’ll explore the key factors that contribute to achieving lightning-fast shifts:

Dual-Clutch Transmissions (DCTs) (100 words): Dual-clutch transmissions are renowned for their lightning-fast shifts. They consist of two separate clutches for odd and even gears, allowing for pre-selecting the next gear while one is engaged. This virtually eliminates the time required for gear engagement and results in seamless and ultra-fast shifts that are a hallmark of high-performance driving.

Paddle-Shift Systems (100 words): Paddle-shift systems are a game-changer in automatic transmissions. Located on the steering wheel, these paddles enable drivers to manually control gear changes, providing a level of precision and speed that was once exclusive to manual transmissions. Modern paddle-shift systems incorporate advanced algorithms for lightning-quick shifts that enhance both performance and driving pleasure.

Launch Control (100 words): Launch control is a technology that optimizes acceleration from a standing start. It manages engine output and traction to prevent wheel spin, allowing the vehicle to achieve maximum acceleration while maintaining control. High-performance cars often feature sophisticated launch control systems that ensure consistent and lightning-fast launches, a critical advantage in drag races and competitive driving.

Rev-Matching (100 words): Rev-matching is a technique used in manual transmissions to ensure smoother downshifts during aggressive driving. High-performance manual transmissions often come equipped with automatic rev-matching systems that blip the throttle to match engine and wheel speeds, resulting in seamless downshifts that maintain stability and prevent loss of traction, particularly in high-speed cornering situations.

III. Advanced Materials and Manufacturing

To achieve the lightning-fast shifts demanded by high-performance vehicles, manufacturers turn to cutting-edge materials and manufacturing processes. This section will shed light on the following aspects:

Lightweight Components (100 words): Lightweight materials, such as carbon fiber and aluminum, are essential in high-performance transmissions. These materials reduce rotational inertia, which directly affects acceleration and deceleration. By using lightweight components strategically, engineers can optimize a transmission’s ability to rapidly change gears, enhancing the overall performance of the vehicle.

Precision Machining (100 words): Precision machining is a fundamental aspect of crafting high-performance transmission gearsets and components. The smoother the surfaces and the tighter the tolerances, the less energy is lost to friction and heat. This precision machining enhances efficiency, reduces wear and tear, and ultimately contributes to lightning-fast shifts while maintaining the transmission’s integrity over time.

Heat Management (100 words): High-performance driving generates significant heat, which can be detrimental to a transmission’s performance and longevity. To address this issue, engineers incorporate advanced heat management systems. These may include improved cooling systems, heat shields, and materials with high-temperature resistance. Effective heat management ensures that the transmission can perform optimally even under extreme conditions.

Computer-Aided Design (CAD) (100 words): Modern high-performance transmissions are not just the result of trial and error but are meticulously designed using computer-aided design (CAD) technology. CAD allows engineers to simulate and optimize transmission layouts, gear ratios, and other critical parameters with precision. This technology ensures that every component is strategically placed and engineered for maximum performance.

IV. Electronics and Control Systems

High-performance transmissions are no longer purely mechanical entities. They are tightly integrated with sophisticated electronic control systems that play a crucial role in achieving lightning-fast shifts. We will explore the following electronic innovations:

Electronic Control Units (ECUs) (100 words): ECUs are the brains behind high-performance transmissions. They continuously monitor various sensors, including throttle position, engine RPM, and vehicle speed, to determine the optimal time for gear changes. Advanced ECUs can process this data in real-time, enabling rapid and precise shifts that adapt to driving conditions and driver input.

Adaptive Shift Algorithms (100 words): Adaptive shift algorithms are a hallmark of modern high-performance transmissions. These algorithms continuously learn and adapt to the driver’s behavior and road conditions. By analyzing a vast array of data, they optimize shift patterns for lightning-fast, yet smooth, gear changes that enhance both performance and drivability.

Manual Mode Enhancement (100 words): Even in automatic transmissions, drivers often enjoy taking control through manual mode. High-performance transmissions enhance this experience with electronic aids like rev-matching and instant paddle-shifting response. These enhancements ensure that drivers can execute precise gear changes manually, akin to a traditional manual transmission but with lightning-fast shifts.

Launch Control and Traction Control (100 words): Launch control and traction control systems are critical for harnessing the power of high-performance vehicles. These electronic aids work in unison to ensure that the vehicle accelerates optimally from a standstill without wheel spin. They manage torque delivery and braking at individual wheels, resulting in consistently lightning-fast launches and exceptional traction in various driving conditions.

V. The Future of High-Performance Transmissions

The automotive industry is constantly evolving, and high-performance transmissions are no exception. In this section, we’ll explore the cutting-edge technologies and trends that are shaping the future of lightning-fast shifts:

Electric and Hybrid Transmissions (100 words): The rise of electric and hybrid powertrains is changing the landscape of high-performance transmissions. Electric motors provide instantaneous torque, requiring unique transmission designs for optimal performance. High-performance electric vehicles often feature single-speed transmissions that deliver lightning-fast acceleration without the need for traditional gear changes.

Advanced Driver-Assistance Systems (ADAS) (100 words): High-performance transmissions are increasingly integrated with ADAS for enhanced safety and performance. These systems work together to optimize gear changes in response to real-time data from sensors, enhancing both acceleration and vehicle stability during aggressive driving.

Sustainability and Efficiency (100 words): In response to environmental concerns, high-performance transmissions are adapting to meet the growing demand for sustainability and efficiency. Manufacturers are exploring technologies like hybridization and mild-hybrid systems, which combine electric and internal combustion power for lightning-fast performance with reduced emissions and improved fuel efficiency.

Autonomous Driving (100 words): The role of high-performance transmissions in autonomous vehicles is a fascinating one. While autonomous cars often prioritize smooth and efficient gear changes, they may still incorporate high-performance transmission technology to provide rapid acceleration when needed, such as in emergency situations or for sporty driving experiences on demand.

Conclusion

In conclusion, the science behind lightning-fast shifts in high-performance transmissions is a captivating blend of mechanical engineering, materials science, electronics, and computer technology. These transmissions are the heart of high-performance vehicles, enabling drivers to experience unparalleled speed, precision, and control. As automotive technology continues to advance, we can only anticipate even more exciting developments in the world of high-performance transmission technology, pushing the boundaries of what’s possible on the road and the racetrack. The relentless pursuit of speed and precision ensures that high-performance transmissions will remain at the forefront of automotive innovation for years to come.