How times have changed. When our Chevy was new there were two choices when it came to transmissions: a three-speed manual or a two-speed Powerglide automatic. Interestingly, when the automatic was ordered it came with a larger displacement engine (235 versus 216 ci) with more ponies (105 compared to 92 hp).

In most cases, when running gear of an early car is being updated, an automatic transmission is the gearbox of choice. They are easy to install and hook up, they’re reliable, user friendly, and there are a variety of designs to choose from. While the array of offerings may seem confusing, like most voices that have to be made, the more informed you are, the easier it is to make a decision. To that end let’s look at the basic parts of an automatic, what’s available, as well as the modifications Gearstar makes to enhance performance and longevity.

Parts are Parts

While automotive transmissions may have two, three, four or more gears, computer controls, and a variety of bells and whistles, the basic internal parts remain the same, there are just more of them in some than others.

Torque Converter

This is what connects the engine to the transmission. Not only does it allow the engine to keep running while the car is stationary, but it can also provide torque multiplication when accelerating from a standstill. For a simplistic explanation of how a torque converter works, picture what would happen if two electric fans were facing each other and one was turned on. As the one under power began to turn and move air, the other one would also begin to turn. If you can visualize that, you’ve got the basic idea of how a torque converter works. In a torque converter, both fans are in a container: one is connected to the engine and the other to the transmission, and oil is used rather than air. As might be expected, there is some slippage inherent with a torque converter, so many overdrive automatics now have converters with a hydraulically applied internal clutch that hooks the transmission directly to the engine for increased efficiency. While better fuel mileage is often considered to be the advantage of a lockup converter, there is another, often overlooked, purpose. The higher ratio provided by an overdrive Fourth gear can put an additional load on a conventional converter causing excessive slippage even in light-throttle, cruise conditions. That slippage creates heat and heat is the enemy of an automatic transmission. When used with an overdrive automatic, a lockup style will lower engine speed in cruise conditions and lengthen the transmission’s life. Overdrive automatics and lockup converters are made for one another.

Planetary Gears

As gears go, planetaries can do it all. Made up of three elements – a sun, ring, and planet pinion gears – they can provide forward or reverse rotation, a speed increase, constant speed, or a speed reduction. Three things are necessary to make planetary gears operate: an input (power from the engine), and output (power going out), and a reactor (one of the elements is held stationary). The gear ratio and the direction of travel depend on which element is performing each function. Most transmissions have more than one planetary gear set to provide a variety of gear ratios.

Bands and Clutches

Bands and clutches hold the reactors stationary. An automatic transmission goes into gear by holding one part of a planetary gear set stationary with a band or clutch that is applied by hydraulic pressure. One reactor is released and another applied when then transmission shifts gears; the transmission is in neutral if no reactor is applied. If you’ve ever been in a car and the transmission felt like it was slipping that’s exactly what was happening – the band or clutch pack wasn’t holding the reactor stationary and it was slipping and not transferring full power. In an extreme case, the clutches, or band, don’t hold at all, and one or more gears (and in some cases, every gear) stop working as a result.

Valvebody

The valvebody is the hydraulic “brain” of the transmission; it controls the shifting of gears by controlling which reactor is applied and when. Some transmissions use hydraulic pressure from a governor, throttle valve, or vacuum modulator to determine shift points, while many contemporary versions use computer-controlled electromechanical servos.

Transmission Modifications

Let’s start with the torque converter. In many cases, the stall speed of the converter is increased. Simply put, stall speed is the rpm that the engine will reach when the transmission in gear, the brakes applied, and the throttle held wide open. The higher rpm simply allows the engine to produce more power, which will launch the car harder from a standstill. The downside is that high stall speed converters will slip more in “normal” use. That can create excessive heat, which is what damages transmissions. Of course the perfect solution is a lockup converter with increased stall speed, which is the best of both worlds.

Shift Kits

Most stock automatics are designed to be seamless. That is, the shifts smooth to the point of being hard to detect. This is done by timing the release and application of the various reactors. One may begin to apply as the other begins to release so there is a split second of overlap. While this results in a smooth shift, there is a certain amount of slippage that takes place in the process, which wears the friction surfaces. Shift kits generally do two things: They change the timing of the release and application of the reactors, which results in a firmer, more noticeable shift and may also lengthen the life of the transmission. In addition the hydraulic pressure to apply the reactors is often increased too, which means the clutches and bands have more holding power, thus increasing the torque capacity of the transmission. With many transmissions today using computer controls, a variation on the shift kit theme is the hopped-up computer. It can and will do the same thing as a conventional shift kit, but changes can often be made without dropping the trans pan.

Friction Surfaces

A common method to increase an automatic transmission’s torque-carrying capacity is to improve the friction surfaces that hold the reactors. This may be done by using improved materials, more clutch plates, wider bands, or a combination of them all.

Hard Parts

Just as with a manual transmission, an automatic has mechanical components that are susceptible to damage when overstressed. As the horsepower applied to it is creased, it is often necessary to increase the strength of an automatic transmission’s shafts, clutch drums, planetary gear sets, sprags, and other internal parts.

Tailoring a Transmission to your Needs

Depending on the customer’s needs, Zack Farah of Gearstar Performance normally recommends one of the following levels of performance enhancement:

Level 1 – Described by Zack Farah as one step above stock, these transmissions are completely remanufactured using improved Alto frictions and a mild shift kit. They are capable of reliably handing 300-plus horsepower and are perfect for daily drivers.

Level 2 – Gearstar’s most popular offering, these transmissions are also rebuilt with all-new internal parts. In addition, the torque capacity of the clutch packs is increased by more than 70 percent, and a more sophisticated shift kit is used for a firm, positive shift. Horsepower capacity is 400-plus.

Level 3 – Equipped with all hardened and stress-relieved hard parts – including shafts, drums, and planetaries – these transmissions are for rods that see the street and part-time dragstrip use and are equipped with high-torque 600-plus horsepower engines. Additional modifications include three different shift kits, expanded capacity clutch drums with Alto Red Eagle frictions, and Kolene steels.

Level 4 – The King Kong of transmissions, these are built to withstand the horsepower a blown big-block can put out. Also popular behind Hemis and big-block Fords, these transmissions have all the Level 3 modifications plus a more aggressive shift kit.

AN OVERVIEW OF GM TRANSMISSIONS

GM has produced a substantial number of automatic transmissions over the years:

Powerglide – First produced with cast-iron cases, and in later years aluminum, these transmissions have two primary applications: restorations of original vehicles and racing. The early versions are often redone for Tri-Five Chevy restorers (Gearstar routinely rebuilds Powerglides and other vintage transmission, please call for more information) and there is practically an entire industry devoted to building them for drag racing.

Hydramatic – The original Hydramatic was a tough by complex four-speed automatic transmission used in a variety of GM vehicles into the ‘60s, including Chevy and GMC pickups, as well as other makes such as Lincoln. These transmissions were so tough that they became some of the first automatics to find favor in drag racing. The Hydramatic was replaced by the much less complicated (and cheaper to produce) Turbo-Hydramatic. As an aside, occasionally vehicles that should have Hydramatics are found with different transmission. A fire destroyed GM’s Hydramatic plant so Oldsmobiles and Cadillacs used Buick’s Dynaflow and Pontiacs used Chevrolet’s Powerglide.

Turbo 350 – These small, compact, affordable three-speed transmissions were the most popular transmission in street rods before the availability of overdrive automatics. Still a viable choice, Farah has seen a resurgence of interest, and it seems to be making a comeback. The Turbo 350 is a great buy at just a little more than $1,000, and comes complete with converter, tv cable dipstick and tube, dust cover, cooler, and fluid.

Turbo 400 – Physically larger and able to handle more horsepower then the 350, the Turbo 400 isn’t as efficient, but is tough. These three-speed transmissions are still an excellent choice for high-horsepower applications, where overdrive isn’t necessary.

200-4R – Because of its compact proportions, many people assume it’s not particularly strong; however, they will handle 800 hp or more with Gearstar’s modifications. Extremely efficient, thanks to a unique bellhousing bolt pattern, it will bolt to any GM engine.

700-R4 – While this is one of the most popular of the overdrive automatics, the 700-R4 does have a reputation for having a difficult-to-adjust throttle valve cable. As improper adjustment can cause erratic shifting and even lead to complete failure, Gearstar has developed the Fail Safe Maximum Pressure Valvebody System, which reverts to high pressure in the event of a misadjusted or damaged throttle pressure cable. A vacuum lockup system is also used, which denies lockup to the torque converter under aggressive throttle application.

4L60 – The latest version of the 700-R4, the 4L60 features a more sophisticated valvebody, but is otherwise the same (including gear ratios).

4L60E – A more refined version of the 700-R4/4L60, the E-series transmissions use an electronically controlled valvebody. The tv cable is eliminated, by a standalone computer is required.

4L65E – There are two models of the 4L65E transmission: the early version bolts to the LT series of blocks, and the later versions uses a longer input shaft and is used with LS engines.

4L70E – Found behind the LS7 engine in the new GTO and Trailblazer SS and SSRs, this newer version of the 4L65E uses larger front and rear five-pinion planetaries.

4L80E – The big brute of automotive automatics, this transmission is larger than the 700-R4/4L60 series and is capable of handling well over 1,000 hp when properly modified.

As you can see, there are many choices when it comes to GM automatic transmissions and the modifications that can be made to them, but if you’re still having trouble deciding, give Farah a call and be prepared to provide as much information as you can, including the approximate weight of the vehicle, horsepower, rear gear ratio, rear tire diameter, and its intended use.

Our Choice: the Gearstar 4L60 – Gearstar is unique in a variety of ways. When the company’s owner, Zack Farah, got his start over 25 years ago at Tristar International they were cranking out 100 transmissions and 300 converters per day. But while high-performance transmissions were a small portion of the business, they were where Farah decided to focus – the result was the creation of Gearstar. As Farah puts it, “A transmission is what your wife has in her minivan. What we are building are horsepower-transferring systems. Whether it is a Turbo 350 going behind a mild small-block or a 4L85E built for a 528 Hemi, we approach each transmission as if it’s going into our own personal car.” He has a team of builders whom he describes as “the best of the best;” one master builder from start to finish handles every transmission.

For our purposes we decided on the Gearstar Level III 4L60. Basically an improved version of the 700-R4, this transmission doesn’t require a computer like any of the later transmission with an E suffix (4L60E and an example). Thanks to variety of modifications and the Yank lockup converter, this transmission is tough enough to endure aggressive launches from a dead stop, yet the overdrive gear and lockup feature make it perfect for highway cruising. This package is recommended for 355/383/396/400/454 naturally aspirated Chevrolet engines producing 450 hp.

Modifications include:

- Yank 10-inch lockup racing with stall speeds ranging from 2,600-4,500 rpm for a stronger launch from a standing start while retaining the advantages provided b the lockup feature.

- Improved reactor holding capacity from Alto Redline racing frictions and band, hardened steels, expanded capacity direct clutch drum, expanded capacity forward clutch pack, and four-clutch overdrive pack.

- A combination of TransGo and Gearstar reprogramming shift kits, Corvette servo and Sonnax “Superhold” 3-4 Servo to provide firm shifts that are timed appropriately.

- A 13-vane high-output pump and 0.500-inch boost valve for higher and more consistent hydraulic pressure.

- For increased strength a 300M hardened steel shaft and hardened, expanded capacity drum, monster sun gear shell, and extreme duty springs and sprags.

| Zack Farah, owner of Gearstar, is justifiably proud of the group he calls, “The best staff in the business.” His crew is proud of what they do as well. Patrick has 30 years of experience, is an ASE master transmission tech, is GM certified, and says with a grin, “I get to build with the best parts, take all the time in the world, and know that it’s going into a really cool car. What more could I ask for?” |  |

|

Gearstar doesn’t crank out rebuilt transmissions for ordinary applications, they specialize in automatics for performance applications, and consequently many of the internal parts are replaced with improved versions. In some cases it could be considered overkill, Zack considers building tough transmission good business sense. |

| Gearstar substitutes stronger, hardened, and stress-relieved 4340 steel shafts in Level 3 and 4 transmissions for reliability. Level 2, 3, and 4 transmissions carry a 24-month, 24,000-mile warranty. |  |

|

Shown here are the front (larger pair, left) and rear (smaller pair, right) planetary gear sets. Both are upgraded from a cast housing with four pinion gears to five gears and a hardened steel housing. |

| This is a great example of Gearstar’s attention to detail. Thanks to a sharp bend made during the manufacturing process, the factory sun gear shell tends to fracture adjacent to the splines. Gearstar’s replacement is made of heavier material and is gusseted the splines for increased strength. |  |

|

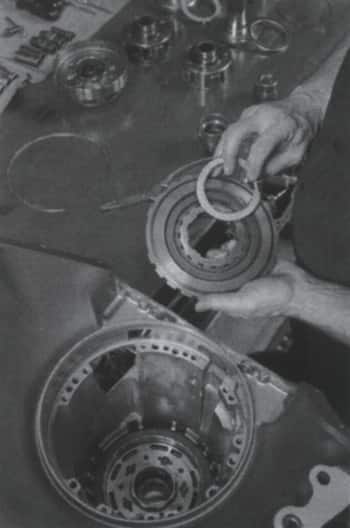

This is the clutch pack for the rear planetary set that provides low and reverse gear – not that steel and friction discs are used alternately. Gearstar uses Alto frictions and hardened steels exclusively. |

| A critical component, this is a sprag, or one-way clutch. In most cases more elements “or peanuts” that rock between the inner and outer races are considered to be beneficial. Gearstar has found that by using one less element and making them bigger, strength is increased dramatically – sometimes less is more. |  |

|

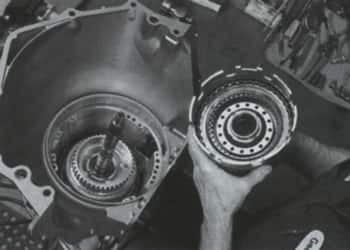

The rear planetary gear set (note the five pinions) fits inside a drum. |

| The planetary assembly is installed followed by the clutch pack and a piston that applies pressure to them. |  |

|

Then again, sometimes more really is more – increasing the number of frictions and steels in a clutch pack increases torque capacity. This is the 3-4 clutch set. |

| Patrick carefully lowers the input shaft and clutch assembly into the case. The rings around the shaft are seals that ensure transmission fluid is directed to the proper place. |  |

|

Here the 3-4 clutch discs have being installed – note the steels have teeth that engaged the outer shell while the frictions have teeth that engage the hub they fit over. |

| The last clutch assembly to be installed is the forward set – it transfers power in First, Second, and Third gears but free wheels in Fourth. |  |

|

At the front of the gear train is the drum for the 2-4 band. Like just about everything else installed so far, Gearstar uses an improved drum and band. |

| A high-performance band wraps around the drum. It’s applied in Second and Fourth gear. |  |

|

Another Gearstar upgrade is the 13-vane, high-output pump. It supplies the hydraulic pressure necessary to shift gears and lubricate the moving parts. Pump pressure is increased for firmer shifts and increased torque capacity. |

| The servo that applies the band is located outside the transmission case near the bellhousing. Gearstar’s piston (right) applies greater pressure to the band than the stocker (left). |  |

|

Compare the stock GM servo cover (left) with the Gearstar replacement (right). |

| With Gearstar’s servo the band is applied quicker while a heavier stock spring (just visible inside the case), making it release faster – all this allows for quicker, crisper shifts. |  |

|

Gearstar’s billet servo cover not only looks trick, it allows more fluid to act on the piston. |

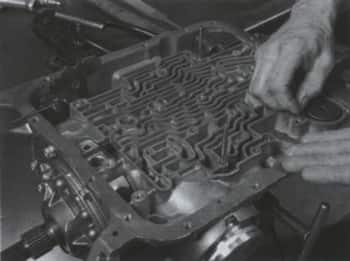

| Looking a little like an ant farm, all those passageways in the case are to direct hydraulic fluid to specific locations to apply a clutch or band, or to lubricate a component. Note the check ball and the guide pins to ensure the valvebody is installed without damaging the gasket. |  |

|

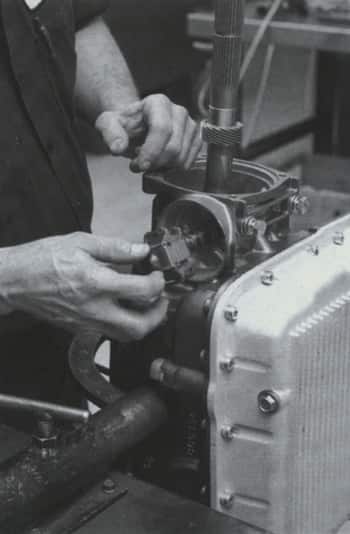

Several variations of shift kits are used in the valvebody to tailor the transmission’s performance to the customer’s needs. It does, however, take a lot more than a shift kit to make a performance transmission. |

| Properly torquing the many bolts in the valvebody is critical to prevent internal fluid leaks. |  |

|

With the valvebody installed, the shift linkage is connected, the fluid distribution tube is installed, as is the wiring for the lockup converter. |

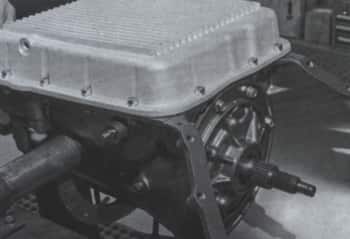

| There are a variety of pans available from Gearstar. We opted for an aluminum version with a drain plug. |  |

|

The governor mounts in a cavity at the rear of the case. It’s something that is often overlooked or modified incorrectly. The governor influences when shifts occur – Gearstar goes to great effort to match the governor weights and springs to the modifications made to the transmission. |

| Another consideration is the type of speedometer drive required. In our case a mechanical drive was required, and electronic senders are also available. |  |

|

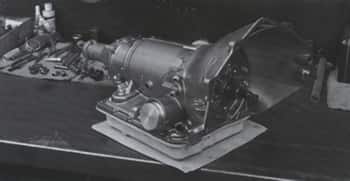

Our finished transmission ready for it’s new home in the ’09 AMSOIL / STREET RODDER Road Tour Chevy. |

| Gearstar has proved that something doesn’t have to be complicated to work well – case in point is their lockup converter control. There are none that are simpler, easier to install, or work better. |  |

Ready to experience top-notch transmission solutions and expert support?