How to Trick the 4L80E

Many drivers take components that work in unison, which allow them to pull the gear shifter of their vehicle into drive and reverse everyday, for granted. Transmissions keep our trucks moving, and when overworked and under-built, are usually the first things to kick up their feet and go into permanent retirement. The number one killer of transmissions is extreme heat, and we would have to say the second is lack of maintenance. What also tends to escalate a transmission failure is too much torque and horsepower being delivered to a stocked or under-built transmission. Think of it like sending a compact car into a brick wall at 60 MPH. If there is not enough meat there, it is going to crumple up like a piece of paper.

Gear Star Performance Transmissions out of Akron, Ohio, remanufactures all sorts of transmissions, stuffing them with all brand new replacement parts, cryogenically hardened and stress relieved, or custom-manufactured 300M steel components, fresh Kevlar or carbon fiber clutches, hardened Kollen steels, Alto Red Eagle Racing Friction clutches with increased surface area by as much as 60 percent and the list goes on. Gear Star builds every transmission to customer specifications and each transmission is built start to finish by only one technician. The beauty of the "one tech for every transmission system" that Gear Star employs is that other hands do not muddle the technician's work. With Gear Star Performance Transmissions' system each transmission is stamped with the technician's initials and matches the invoice every time. Another unique Gear Star Quality is that the company replaces components inside the transmission whether they need it or not so when your transmission comes back it is new all the way through. After a few years of extreme towing we noticed that the 4L82E overdrive transmission in our '99 Chevy CK2500 was beginning to slip quite aggressively. Intrigued by the Gear Star touch, we yanked the factory unit out and sent it to them for a complete overhaul. We simply told Gear Star's Zack Farah that we used the truck frequently in the summertime and pulled approximately 6,000 pounds, and he took care of the rest. What we got back was a gear-grabbing, torque-delivering transmission that just plain works. Follow along as we show you how Gear Star tricked the 4L80E.

|

|

Zack Farah poses next to our freshly remanufactured 4L80E with all the Confidence in the world in its performance. We plan to put this transmission through towing and daily driving hell, and we know that Gear Star's treatment will hold up to it. |

|

You won't find much on the shelf in the way of complete trannys at Gear Star. This elite performance transmission builder tailors each tranny to the individual's needs. Two main arteries must be in play in order to be successful with a business of this nature. One is customer service and the other is repeatability. Customer relations is the only way to obtain feedback on needs vs. quality and repeating tolerances and strength mods are the only way to develop the product line to the next level. Both of these principles are definitely in play at Gear Star. |

|

|

|

Each Gear Star transmission is run on a dyno for longer than usual to ensure the basic functions are intact. Each tranny is put through a series of test based of its build requirement. After the 220-Hp dyno has run the tranny through its series of tests and the break in, the unit is drained, cleaning the system of assembly lube. After assembly each Gear Star remanufactured transmission is put on the dyno to check for proper shifting, to investigate for any leaks, etc. Once it is given a clean bill of health it will be loaded in a crate and shipped to the customer. What the customer gats back is a turnkey transmission ready to go back in the vehicle and provide reliable service. |

|

Three different valve body configurations help to make four performance levels to fit most any need. |

|

|

|

Much like the unspoken magic of a Funny Car clutch, the torque converter setup dictates how the engine power is transferred to the other drive components. |

|

Gear Star uses high quality synthetic ATF lubricating fluid to extend the transmission's life. With a housing full of fresh CNC 300M billet steel parts, it's a good idea to make sure you keep thermal expansion from friction under control. Gear Star uses synthetic tranny fluid to control heat developed by friction and it's in your best interest to follow suit. |

|

|

|

Because the 4L80E has been in service since the mid '90s, it's gone through three generations of changes. The latest rendition of GM's heavy gas hauler trans is known as the 4L85E. With it comes some substantial strength changes. Gear Star upgrades all of its stage 111 4L80E transmissions with all the 4L85E benefits, such as this planetary segment shown here. Most planetary assemblies use four planet center section. The 4L85E uses a fifth planet to provide additional gear contact and added gear surface contact. This spreads the load over the added gear contact providing strength. Gear Star has the components from the tranny that they don't remanufacture cryogenically treated, such as the planetary assemblies. The process, rather simplistically explained, takes the component for tempering to �300 degrees F. The item is left at that temperature for a predetermined duration till the component is brought up to 300 degrees F until it becomes heat soaked, and finally it's cooled until ambient equilibrium is reached. This tempers the material by aligning the molecule with controlled thermal treatment. |

|

All of the bearings that are the liaisons between cryogenic and billet 300M material are built to accommodate the different thermal expansion rates between the two materials. Gear Star has these bearings made so an occasional added benefit will also be incorporated into the bearing design. Shown here are grooves that provide additional lubrication to the planetary gears. |

|

|

|

On the left is the stock hub. Gear Star's Level 111 is upgrade with their 300M billet steel unit. 300M steel is made of carbon, chromium, iron, manganese, molybdenum, nickel, phosphorus, silicon, sulphur, and vanadium. A specific mixture of these elements are melted under vacuum and quenched to form a low alloy steel of very high strength. It's basically 4340 forged steel with a bit more silicon, vanadium, carbon, and molybdenum content than 4340. 300M provides incredible strength, resists fatigue, yet till has excellent choice for loads bearing 280-ksi to 305-ksi. A ksi is about 1,000 per square inch, so in reference 300M can sustain 287,247-psi to 305,014-psi. Many bearings in a stock 4L80E are a coated aluminum, which makes it cheaper to mass manufacture. This is another component that doesn't play well with power. Gear Star converts all of these bearings to brass. |

|

The pump body is ported to increase the pump's volume output. Pump volume is relative to line pressure, so these modifications also increase the transmission's ability to generate pressure. |

|

|

|

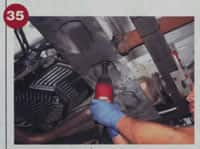

Because of the Gear Star's success in the strength of their stage 111 4L80E, they built adapters so it can be used for most any V-8 domestic powerplant. Sown here are the 426 Hemi adapters. To make the 4L80E plug-and-play ready a O balance flywheel and starter are incorporated into the adapter design. |

|

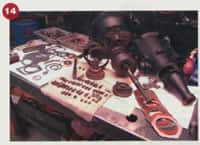

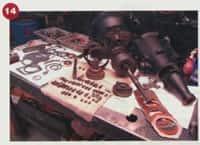

Because each trans is built to your specs, every Gear Star tranny is dissembled and rebuilt by one tech. This way meticulous attention can be paid to each tranny build-up. No parts are reused in the builds, and as you'd expect, all of the bushings, seals, rings. And gaskets are replaced as well, including a few other parts like the all new sensors from GM. |

|

|

|

Here the cryo-treated drum is fitted with the custom-built 300M input shaft with a custom bearing for expansion. The precision 300M splined shaft mates perfectly to the drum. With the pump body modified for added pressure and flow, the fitment of the splines is set so the expansion deferential between the materials with the added lubricity doesn't allow them to grow and gall to one another. |

|

The stock clutch pack uses a two-stage clutch that provides a progressive trans engagement. While great for that smooth shift grandma likes, it doesn't pay homage to the performance-minded positive feedback provided by a firm shift. |

|

|

|

To address the issue of less efficient clutch material Gear Star uses Alto Red Eagle racing Frictions, Raybestos Gen ll Racing Blues or hardened Kollen steel clutch plates. Some clutch hubs are re-machined or custom manufactured to increase the number of clutches and plates. At a minimum, the transmission's clutch engagement surface is increased by 60 percent. |

|

Should your trans be ordered with a deep pan, the pickup tube will b customized by moving the filter deeper into the pan; this ensures that the transmission draws the coolest fluid in the pan. |

|

|

|

Gear Star uses Yank torque converters to complete their upper level tranny builds. Yank's Truck Thrusters are not a retooled or re-stalled version of the stock GM converter, but a brand new design that is a Yank exclusive! The 278mm (11 inches) size is slightly smaller than the stock 300mm (12 inches) and has substantially different driving characteristics. The maximum stall on a factory GM 5.3L torque converter is 1,600 RPMs and the shifts drop about 2,600 RPMs between shifts. With the new Yank Truck Thruster 2600 torque converter, your 5.3 engine will now stall at 2,600 RPMs and the 2.1 Stall Torque Ratio (STR) will multiply more starting line torque than the factory 1.9 STR. This'll shave anywhere from 0.3-0.4 seconds off your 0-60 E.T.s. |

|

The oversized lock-up clutch of the Truck Thruster 2600 will allow you t maintain the full towing capability intended by your OEM torque converter. The greater stall built into the Yank design keeps the converter locked, which provides 300-RPM less for each gearshift. On average your truck loses 2,200-RPM when running through the gears. With the Yank converter the amount lost between shifts is now reduced to 1,900-RPM. |

|

|

|

We took our tyranny issue to Huntington Beach Transmissions where we received a warm welcome and fast service. When ordering any parts make sure you note every detail about your vehicle. If you have a digital camera, shoot some pics and fax or email them to the shop. |

|

The first order of business is to remove all of the linkage, fuel lines and wiring harnesses from around the tranny. |

|

|

|

With a four-wheel drive unit this job might be a little harder. But the two wheel drive shown here, is a bit simpler. Our 3/4 ton Chevy has a flange that holds the front drive shaft and trying the yoke in will prevent transmission from pouring out of the trans snout during removal. |

|

The driveshaft career bearing was removed from its cross member for the inspection of the bearing and rear shaft. |

|

|

|

Unplugging the o2 sensors id a must before attempting to remove the cat-forward exhaust tubing; not doing so will lead to a costly mistake. |

|

The bellhousing "scatter shields" actually does perform a service, so make sure you put it back on. Remember that cleanliness will help you pinpoint failure. Make sure you can clean all of your old parts; it'll make your install procedure 100 times nicer. |

|

|

|

A large diameter converter is actually better than a small converter fasteners with a socket, universal and a extension |

|

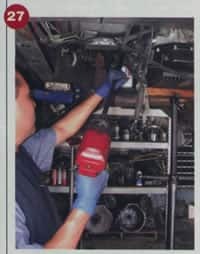

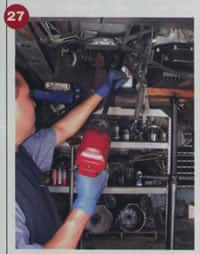

Don't fear the extension. We see so many people squeeze themselves into tight spaces unnecessarily. Our tech used a long extension and blew the bolts off with the impact in seconds instead of hours. |

|

|

|

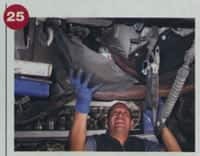

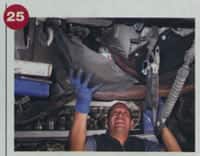

Have you ever performed work without using tools for the job, only to find out that you could have made your life 10 times easier if you'd just gotten out the cash to buy the tool? Yeah, a vehicle rack is defiantly one of those tools, and the tranny jack's nice, too. |

|

Our flex plate was looking a little like retired hockey player, so we took the opportunity to replace it. Always remember, an apple a day... |

|

|

|

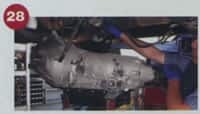

Freshly uncrated our new power transfer system was caulked up on the tranny jack and hoisted into place |

|

The transmission's electronic control wiring harness is often glued into the trans plug. Whatever you do, don't try prying it out with a screwdriver. Go to your local hardware store and buy a cheap, small, handheld torch. Set the torch on low and without letting the flame come into direct contact with the plastic, it's heat the plug only. If you smell burning plastic, it's getting too hot. You should start to smell burning glue (Red Locite to be exact). If you don't know the difference purchase some Red Locite and plastic, burn some Locite with the torch so you know what to sniff for. As soon as you smell the Locite remove the flame. Use a damp cloth over your work gloves, grab the connector, and pull. It should pull free. |

|

|

|

The linkage was installed and checked for function. |

|

Then the converter was attached to the new flex plate, and the shroud was reinstalled. |

|

|

|

The cross member and tranny mount were tightened to spec. |

|

After making sure that the driveshaft carrier bearing was functioning properly, it, along With the drive line, was installed and the truck was set back on the ground. |

|

|

|

As requested by Gear Star, the tranny was topped off with premium synthetic transmission fluid. Oh, by the way. Gear Star performance transmissions all come with intended shift pressure and cycle duration. If you have a chip, programmer or flash program that modifies the shift pressure, it's recommended that you return the PCM back to its stock configuration. With Gear Star's transmission pump mods, the tranny can build enough pressure to destroy itself. Any program mods should be discussed with Gear Star. This way you get what you want instead of a perfectly worthless transmission. |