Building high-performance transmissions is not a job for Zack Farah, it’s a way of life. The owner of Gearstar Performance Transmissions quite literally sleeps, eats and breathes his business, taking tech calls at all hours of the day and night – even once answering his phone during Thanksgiving dinner, which resulted in selling a transmission. But it’s not transmission that he’s so passionate about.

“Gearstar helps people live their drams. I tell my (staff), ‘We don’t build transmission. We build horsepower transferring systems for people’s babies, their pride and job.’ A dependable, performance transmission means they can live their drams, not be stuck on the side of the road,” he says.

Zack has been in the transmission business nearly his entire life. Growing up in the family business, which was the largest remanufacturer of transmissions and converters in the U.S., Zack started out sweeping the floors as a kid and “graduated” to the core deck, where he stood on a receiving deck in all kinds of Ohio weather unloading transmission cores from trailers and logging them into the system to begin the remanufacturing process. “I’ve worked in every aspect of this business, so it made it easier to know what to do, and what not to do, when I started my own company,” he says.

He founded Akron, Ohio-based Gearstar in 2002 to focus solely on high-performance transmission and brought eight key employees from the previous company he managed with him. Unlike other companies, Gearstar only sells transmissions paired with torque converters and dyno-tests each one before it ships the unit to the customer. The dyno-testing process allows Gearstar to make any necessary adjustments to ensure dependability and performance. “Because of the extra effort we put in during building, less that one percent of our units are returned, versus the 30 percent industry standard,” says Zack.

Just the same, Gearstar’s products come with a 30 month standard warranty, the longest in the business, and Zack says he’s never turned down a warranty claim even with a transmission that is beyond the warranty period. “To me, transmissions are like engines. When they are built and installed correctly, you should only need one per car,” says Zack.

Standing behind the product is something Zack and the entire Gearstar team does without fail. Each unit is hand-built by one master builder from start to finish and the customer is encouraged to speak to that builder at any point during the build process, during or after installation.

“When someone calls to place an order, they talk directly to one of our five builders. The builder asks a series of questions about the person’s needs and their vehicle to ensure they are selecting the proper transmission,” Zack explains. Occasionally, a customer wants to order a transmission that the builder realizes will not support the engine over the log term and they will guide the customer to the right match.

In the event the customer argues about the choice, Zack stands behind his builder. Zack says, “Sometimes it’s necessary to lose a sale. We don’t want to have our customers stuck on the side of the road with a blown transmission because we let them buy a unit that we knew wasn’t suitable for their vehicle. It’s us they’ll be angry with, not themselves.”

While Gearstar may lose a few orders with this approach, it has no shortage of customers. It generally has a minimum wait time of four weeks for an order to be shipped and orders sometimes take upwards of eight weeks to ship. “We are a totally custom shop, so we don’t keep any product on the shelf. We don’t focus on meeting any quotas. We focus on quality,” Zack says.

That doesn’t mean, however, that a rodder whose car is down due to a broke transmission (of any brand) has to miss the rodding season. “We know people only have a limited season to drive their cars or that sometimes things happen right before they headed on vacation to a run,” he says. “In those situations, I’ll see if one of the builders wants to earn double time by working on a Sunday and I’ll bring him in to get that transmission built, absorbing the extra cost.”

Once an order is placed, it’s assigned to a builder who has expertise in that type of transmission and he builds it expressly to that customer’s needs. That process includes using a variety of housings to accommodate space constraints, custom calibrating the valve body for the shift feel the customer wants and dyno testing it to simulate all the driving shift points and shift timing for what equals 50 to 100 miles on the road. “The dyno allows the builder to rotate the trans 180 degrees to access the valve body and recalibrate anything that needs to be adjusted, so it’s incredibly useful,” he says.

Once final adjustments are made, the transmission and torque converter are crated for shipping, packaged with three quarts of fluid to be added at installation to the eight already in the transmission from testing. When the customer receives it, he’s encouraged to call the builder at Gearstar with questions anytime, as the tech lines are manned seven days a week from 7 am to 10 pm, with the builders rotating responsibility for taking calls during evenings and weekends. “We know people are generally working on their cars on nights and weekends and we want to be available to them for any questions when they need us the most,” says Zack.

Today, Gearstar has 10 employees in its 6,000 square-foot Akron, Ohio, facility, a former train depot built in 1900 that Zack restored, and a small staff of torque converter builders who operate out of a separate location in nearby Cleveland. Zack calls the business his “obsession” and says he doesn’t expect to eve do anything else as a career during this lifetime. Just the same, he’s reduced his schedule from the 14 to 16 hour work days he did when he first launched Gearstar and now finds time to enjoy driving his 2000 Chevy Camaro SS that was one of the last cars built by Wheel to Wheel. “It’s got an 850 horsepower C5R LSX engine, a 4L85E Gearstar transmission and a 300 shot of nitrous and I drive it during the summer as it if were a Honda, taking it to lunch and running errands,” he says. A ’33 Ford roadster is also in process over at Lobeck’s V8 shop.

In his spare time, he’s working on restoring the old farmhouse he lives in and attending horse shows to watch his 16 year old daughter Sophie compete. Of course, even in Zack’s down time he finds himself doing a little business. “We’ve been building a lot of transmissions for trucks that pull horse trailers lately,” he says with a laugh. “I guess that’s why I call Gearstar my obsession!”

| Once an order is placed, it’s assigned to a builder who has expertise in that type of transmission and he builds it expressly to that customer’s needs. |  |

|

Dave Dale installs a drum assembly at his workbench. |

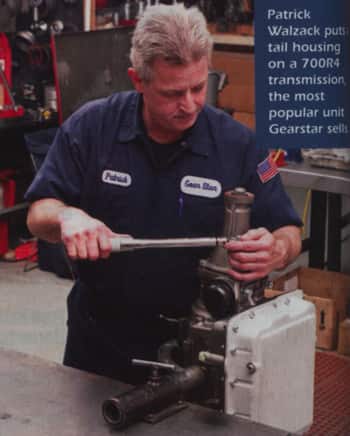

| Patrick Walzack puts a tail housing on a 700R4 transmission, the most popular unit Gearstar sells. |  |

|

Before it is shipped, every transmission is dyno tested to simulate all the driving shift points and shift timing for what equals 50 to 100 miles on the road. |

| Shop manager Mark Walk installs a pan on a transmission. |  |

|

The Gearstar team in available seven days a week to answer questions. It includes (from left to right) Patrick Walzack, Dave Dale, Doug Keagi, Zack Farah, Mark Walk, Kathleen Raines, plus Brian Haney and Steven Welcom, who aren’t pictured. |

| Once final adjustments are made, the transmission and torque converter are crated for shipping, packaged with three quarts of fluid to be added at installation to the eight already in the transmission from testing. |  |

|

In his spare time, Zack attends horse shows with his wife Holly (left) to watch his 16 year old daughter Sophie (right) compete. |

| Owner Zack has been involved in building transmission his entire life. Here he’s testing one of Gearstar’s 4L65E Level III transmissions. |  |

Ready to experience top-notch transmission solutions and expert support?