Switching Gears

Transmissions are pretty much the most ignored component on a vehicle in terms of maintenance. People take transmissions for granted: and don’t think the slightest bit about the amount of heat that goes through them or the amount of wear and abuse they take to enable a vehicle to move, achieve highway speeds and cruise at manageable RPMs with crisp gear changes. When a transmission kicks up its feet and retires you can definitely feel it and hear it.

One of the most popular gearboxes throughout the mid to late 90’s in 1/2-ton GM pickup trucks was the 4L60-E. This is an overdrive unit that served a long tour of duty on the assembly lines, and with countless vehicles out there utilizing this transmission for daily service it seemed like a great model to overhaul.

We turned to Gear Star Performance Transmissions in Akron, Ohio, to put together a stout 4L60-E for the ’97 C-1500 Chevy we were working on. The company builds each transmission as a custom unit and does not keep transmissions in stock to fill orders. They take into account the horsepower and torque of your engine, and also what the vehicle (a truck in our case) is used for. For example, a transmission going behind a 1,000-HP race car engine will be set up entirely differently than one going in a 1-ton truck built to tow heavy loads. Gear Star builds each transmission to spec and only one technician touches each gearbox from start to finish. “This is not an assembly line business, and every transmission is dyno tested and monitored for shift pressure, temperature, input, output, and cooler flow before it is crated up and shipped,” says company owner Zach Farah. These transmissions are 100 percent custom built to the customer’s specific needs and are not an off-the-shelf component.

With a fresh 4L60-E arriving at IMZZ Industries in La Habra, California, we hoisted the old C-1500 up on the lift and got started. Follow along to see hoe Gear Star can restore performance to your pickup.

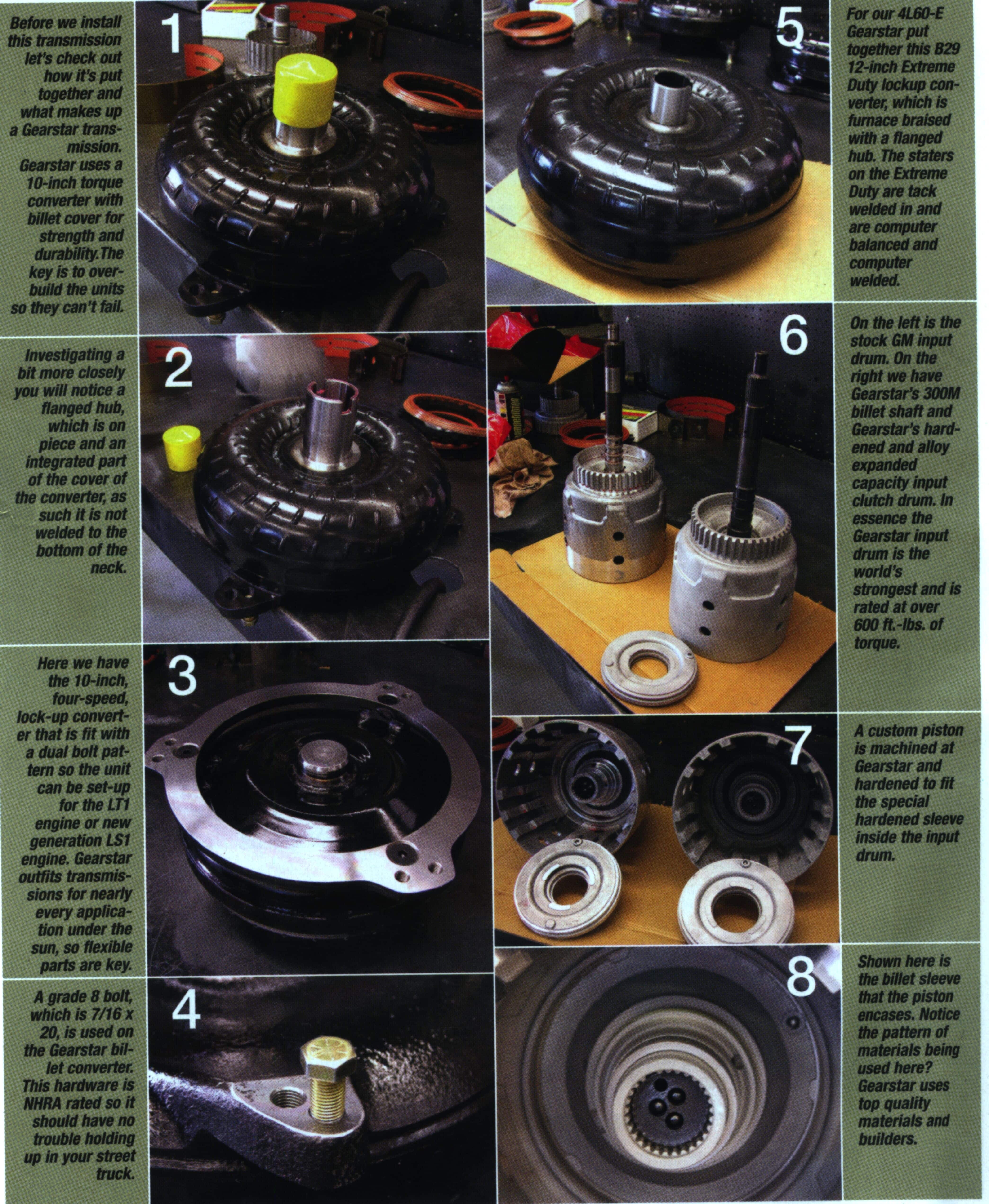

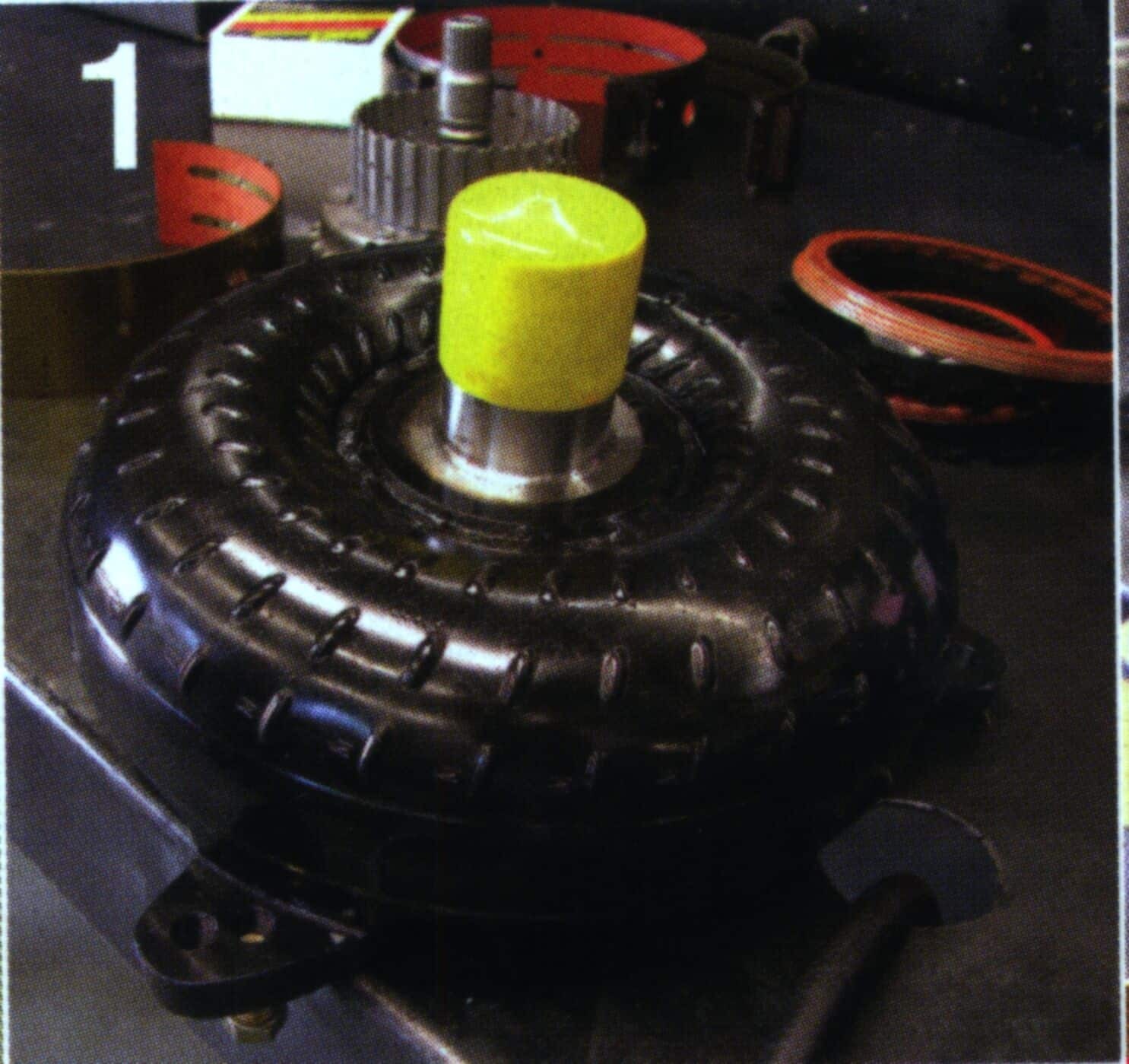

Before we install this transmission let’s check out how it’s put together and what makes up Gear Star Transmission. Gear Star uses a 10-inch torque converter for strength and durability. The key is to over-build the units so they can’t fail.

Investigating a bit more closely you will notice a flanged hub, which is on piece and an integrated part of the cover of the converter, as such it is not welded to the bottom of the neck.

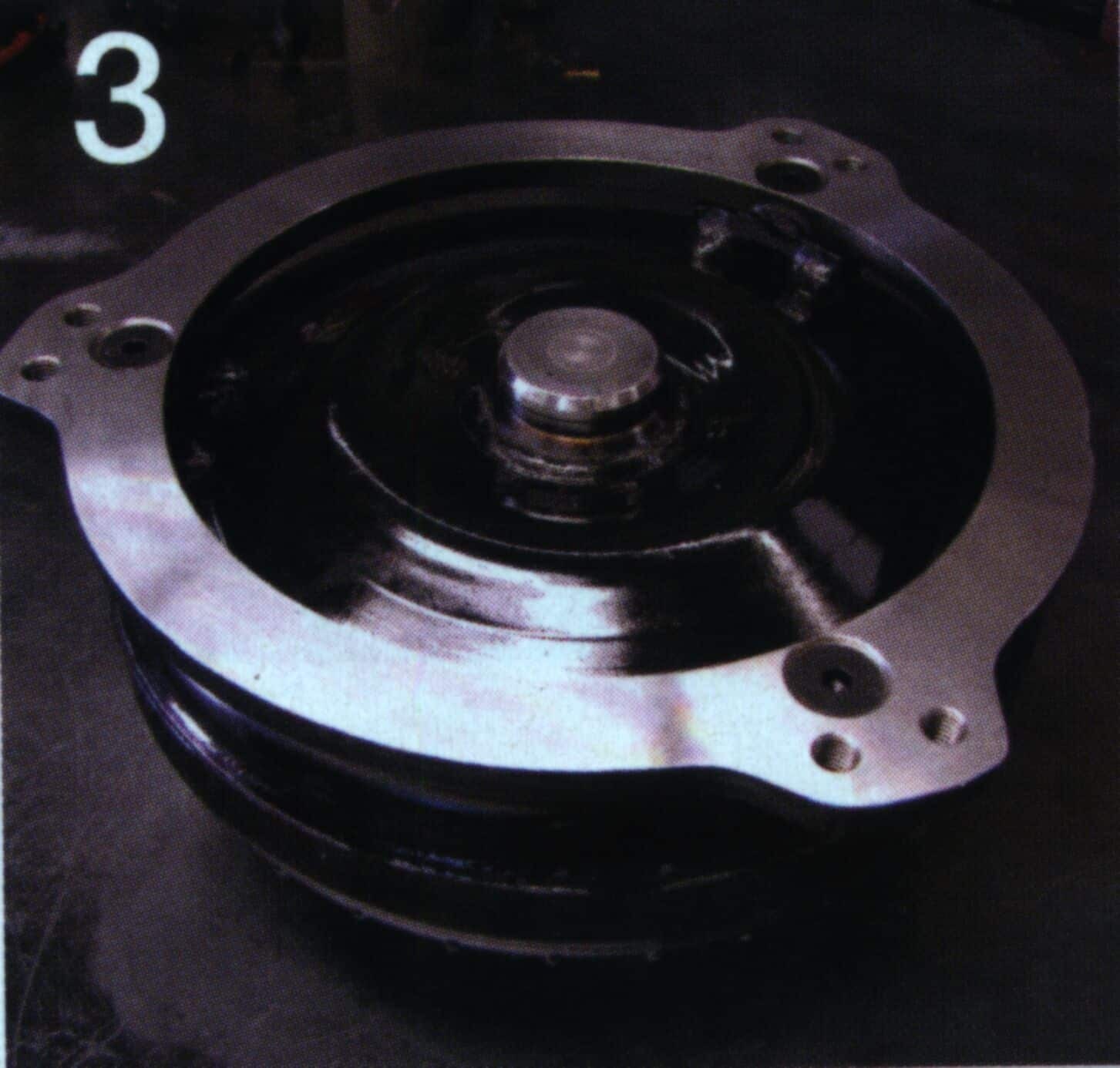

Here we have the 10-inch four speed, lock-up converter that is fit with a dual bolt pattern so the unit can be set-up for the LT1 engine. Gear Star outfits transmissions for nearly every application under the sun, so flexible parts are key.

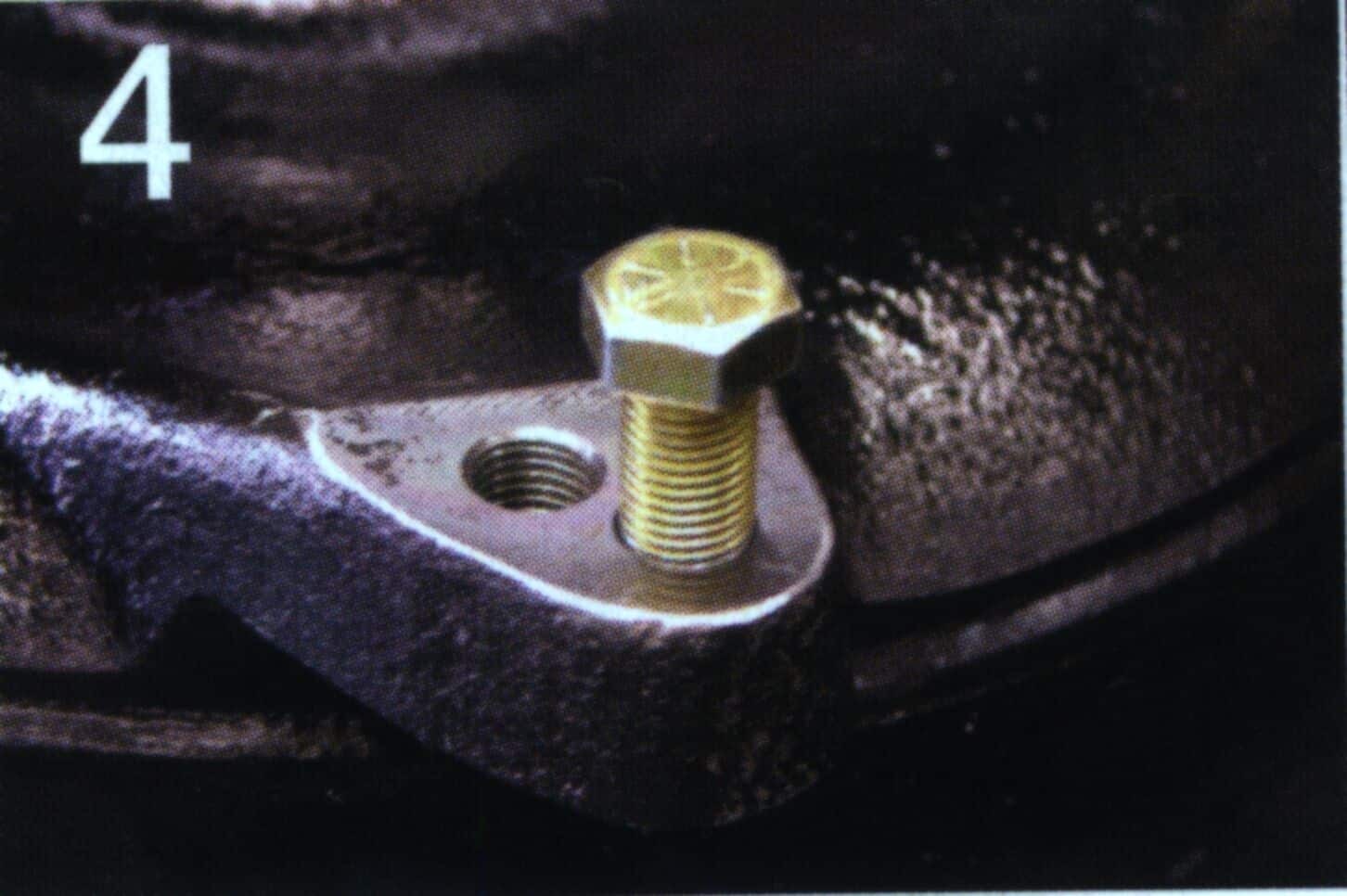

A grade 8 bolt, which is 7/16 x 20, is used on the Gear Star billet converter. This hardware is NHRA rated so it should have no trouble holding up in your street truck.

For our 4L60-E Gear Star put together this B29 12 inch Extreme Duty lockup converter, which is furnace braised with a flanged hub. The staters on the Extreme Duty are tack welded in and are computer balanced and computer welded.

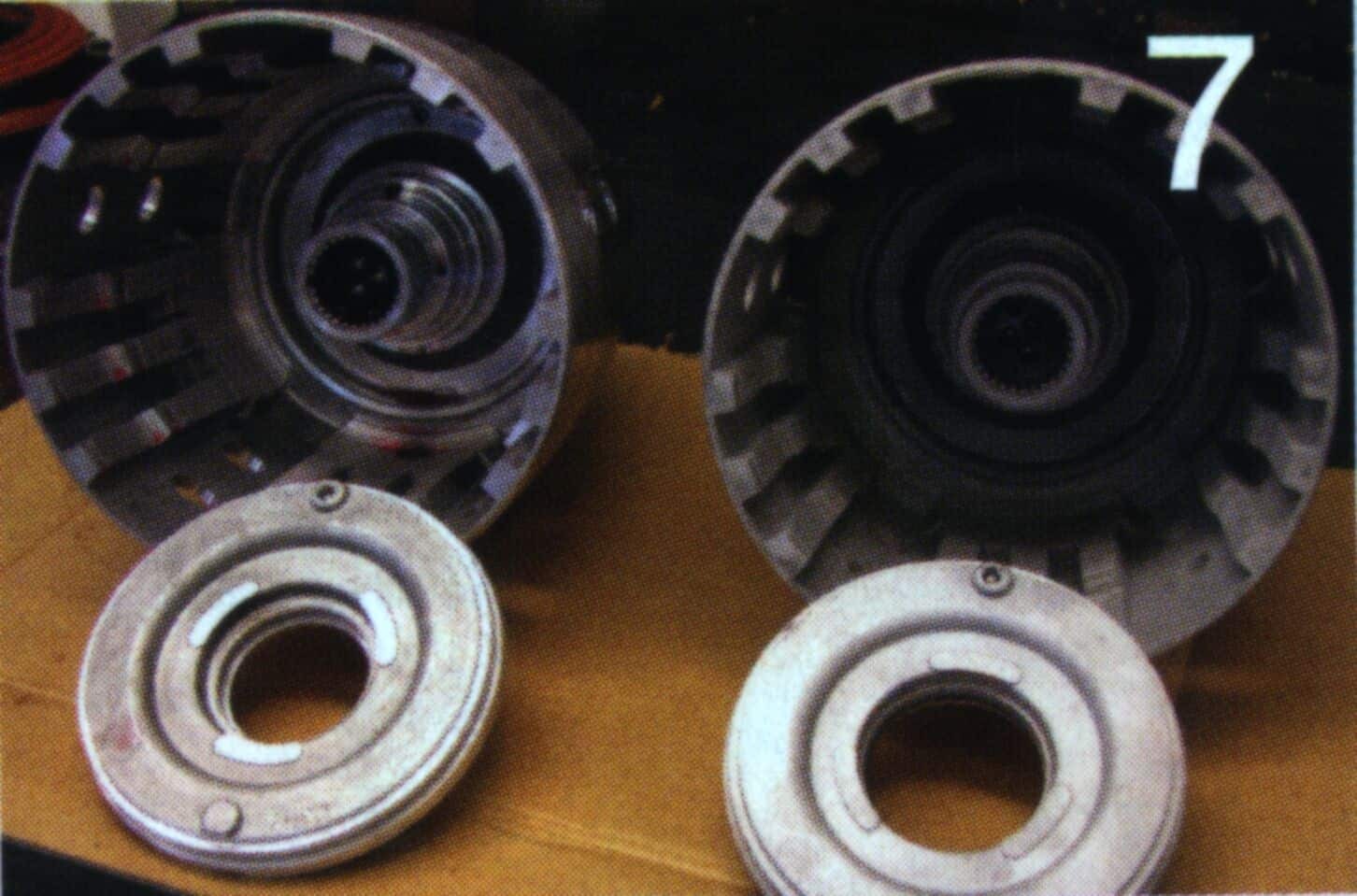

On the left is the GM input drum. On the right we have Gear Star’s 300M billet shaft and Gear Star’s hardened alloy expanded capacity input clutch drum. In essence the Gear Star input drum is the world’s strongest and is rated at over 600ft.-lbs. of torque.

A custom piston is machined at Gear Star and hardened to fit the special hardened sleeve inside the input drum.

Shown here is the billet sleeve that the piston encases. Notice the pattern of materials being used here? Gear Star uses top quality materials and builders.

The black 300M hardened race and custom bearing will outfit our 4L60.

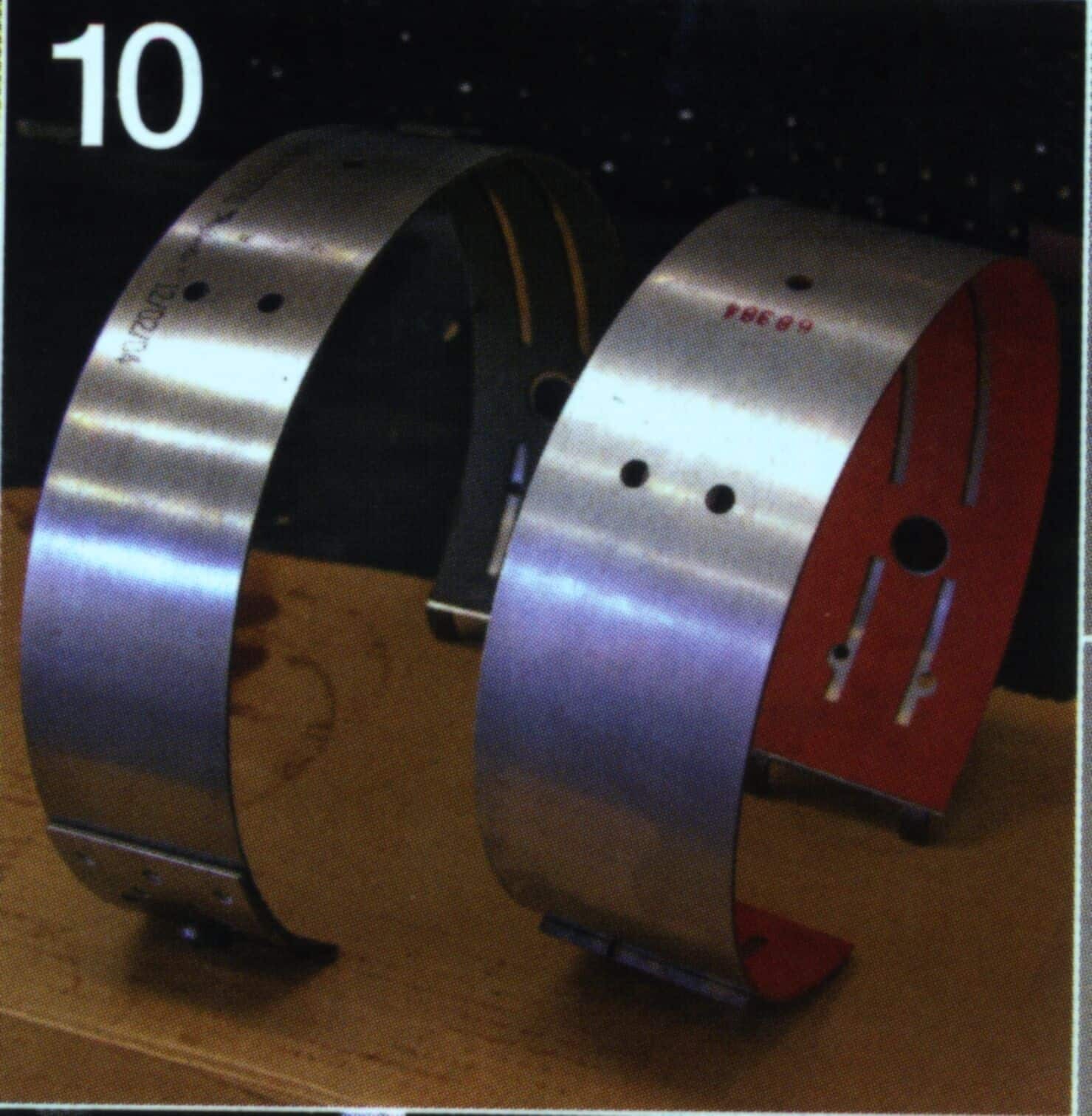

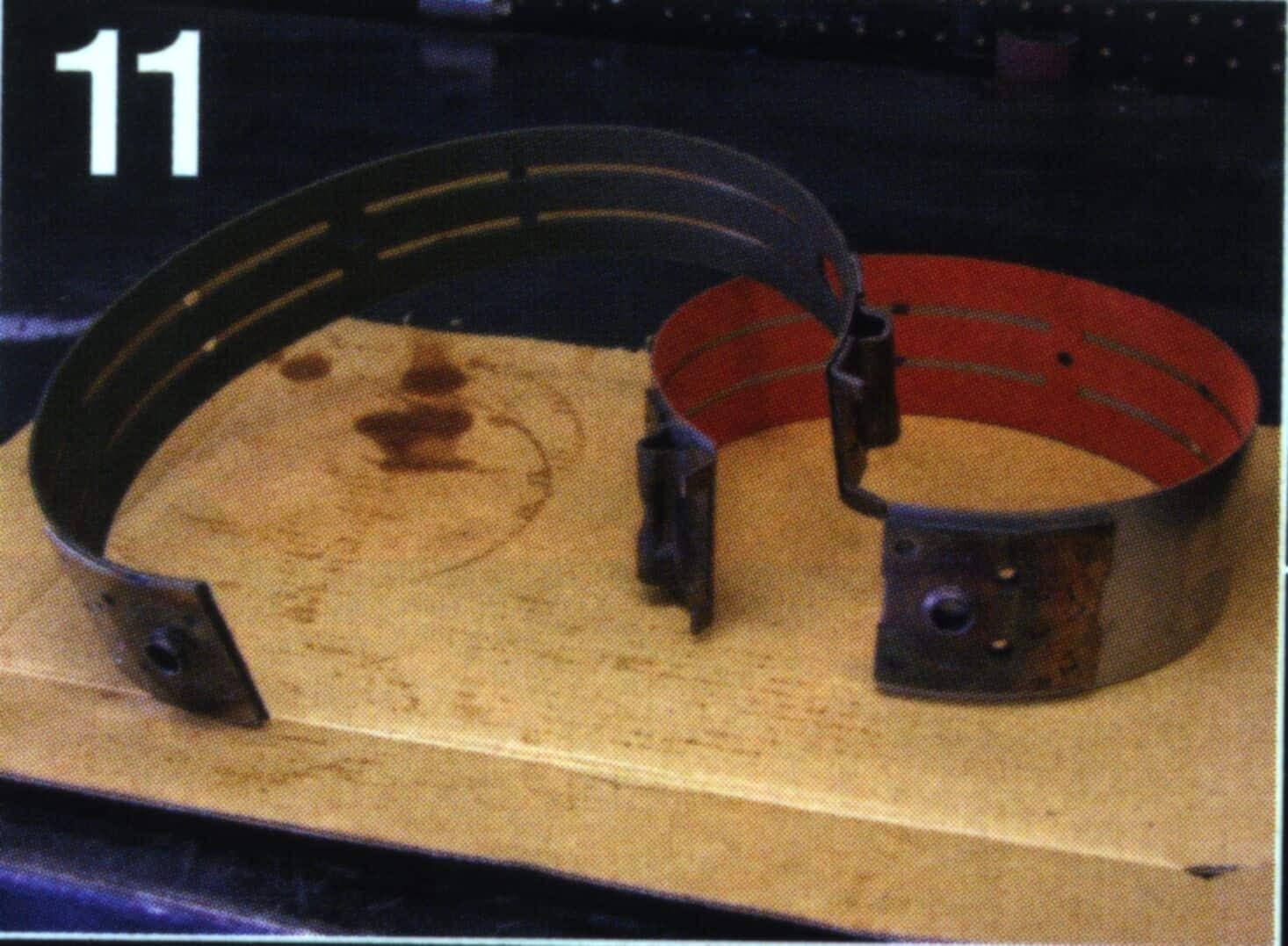

Shown here is the double wide carbon fiber clutch band with Kevlar lining on the right. On the left is the stock clutch band. A reinforced and hardened anchor plate makes the Gear Star clutch band even more durable.

The stock clutch band with reverse drum has 20 percent of the drum exposed, which translates into grabbing power of the reverse drum. This grabs through 2nd and 4th gears, so durability like most transmission parts is key here. The grabbing surface is significantly less than Gear Stars reverse drum.

The Gear Star system features 100 percent coverage of the reverse drum, providing superior holding power of the gear. A reinforced anchor is much stronger than the stock anchor.

This photo shows the stock OE 1st & 2nd gear servo.

Shown here up top is a corvette servo which is a step above stock. Looking below you will notice the Gear Star billet servo that features more apply-surface, which results in a firmer and more positive shift. The Gear Star billet servo also produces better line pressure.

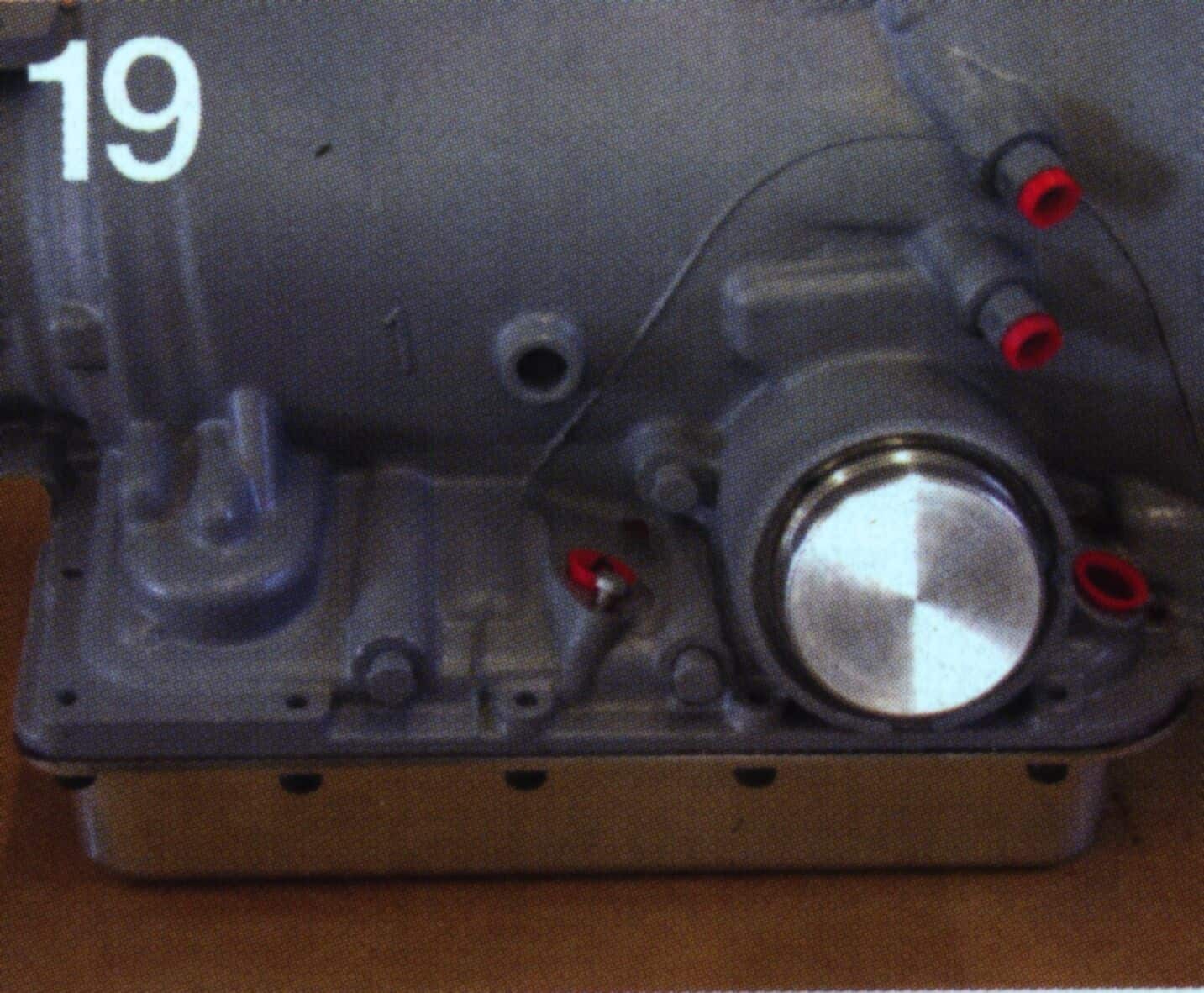

On the left is a four-pinion stock rear planetary gear. Featured on the right is the five-pinion rear planetary carrier Gear Star uses. Their five-pinion unit is steel not cast and is made in America. The crew at Gear Star is adamant about using only American made parts in their gearboxes. An offshore five-pinion planetary gear is $35 and a steel American five-pinion planetary is $180. gear Star goes the extra mile to put top quality parts in their product.

On the left is 3rd and 4th gear stock clutch packs. In the middle row we have forward clutch packs that come on in the transmission and stay on throughout the transmission’s use. Gear Star has eight friction and eight steel forward clutch packs and Gear Star uses carbon fiber clutch materials on the frictions for durability. Also shown in this image are Gear Star’s hardened Kolleene steels, which are used in favor of regular steels. This is the surface that takes abuse on acceleration and deceleration, so due to the extreme wear they endure they must be tough.

On the right is the stock steel and on the left is the hardened Kolleen steel from Gear Star. There is no substitute for putting good solid parts in your gearbox.

Here is a close up of the Gear Star 4th gear billet servo which is designed to apply additional line pressure on 4th gear for a crisp shift.

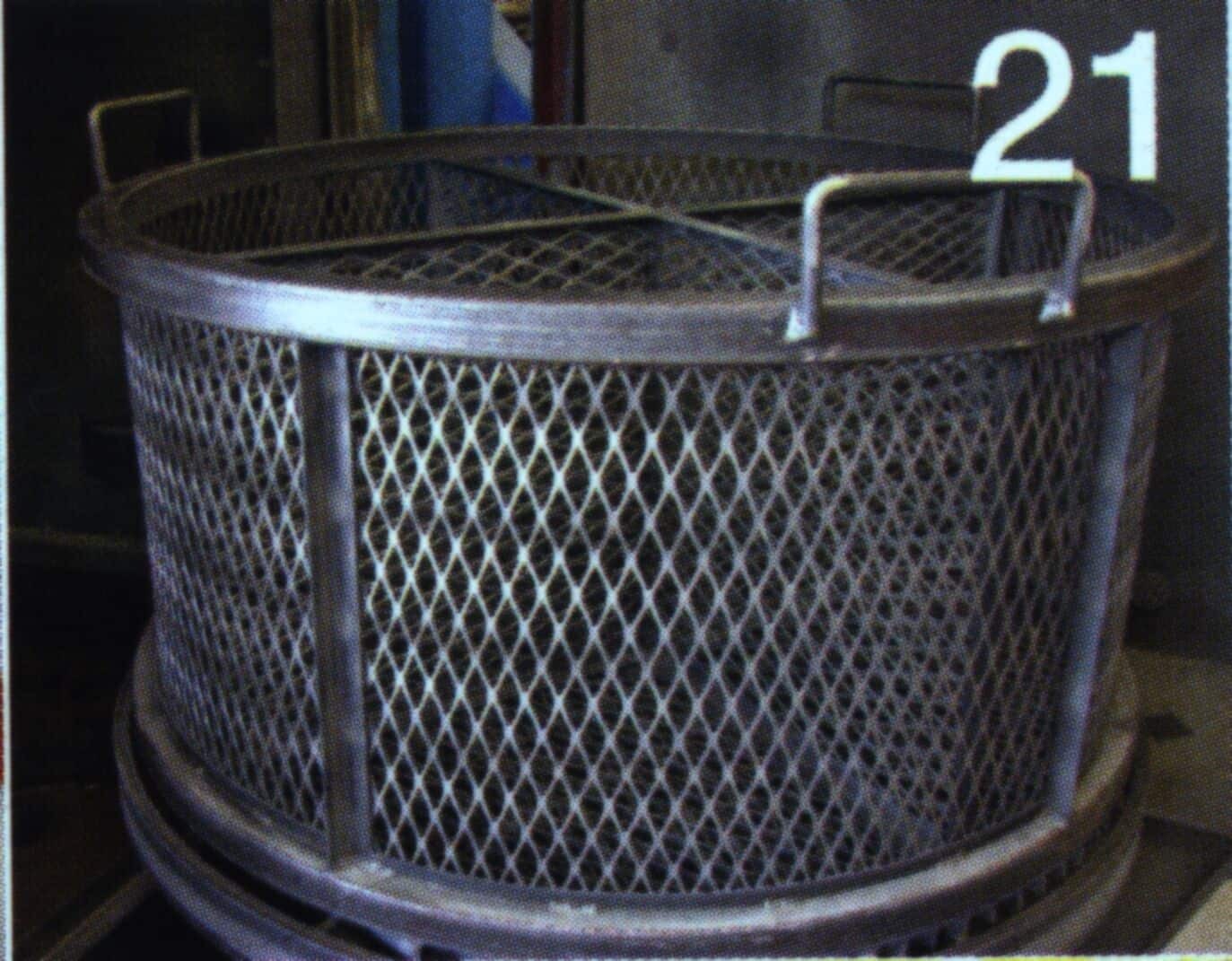

This machine is a MART custom made, high pressure washer, which uses every natural resource known to man including electricity, gas, air, and water. It costs $88,000 and is used to wash all of the transmission cases thoroughly before assembly.

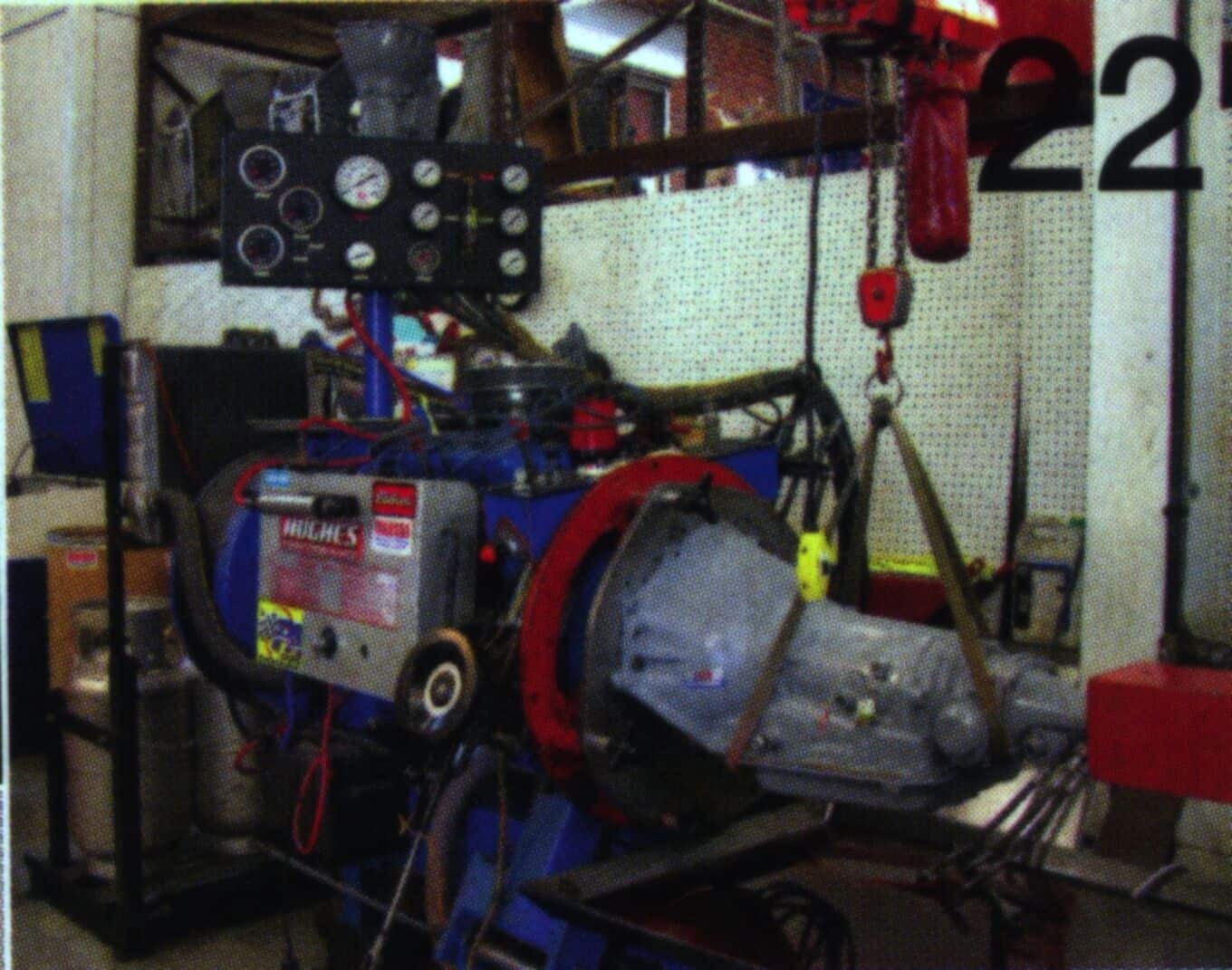

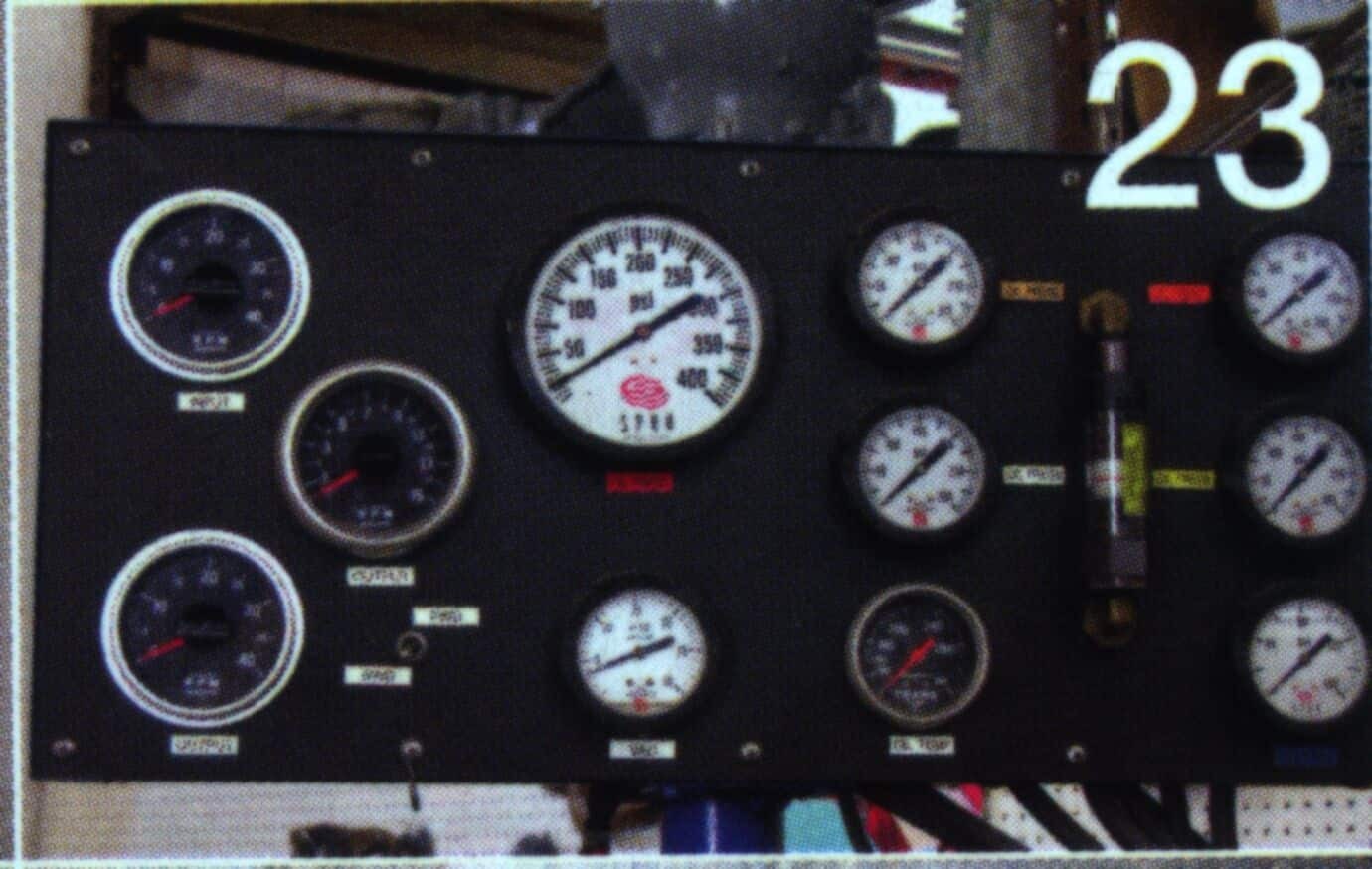

Pictured here is the AXI-Line dyno drome dynamometer. Each transmission after it is fully assembled is tested here before it is crated and shipped. The gauges monitor pressure, speed, input, output, temperature, and pressure of cooler flow. The redline and shift points are set here according to the customer’s needs.

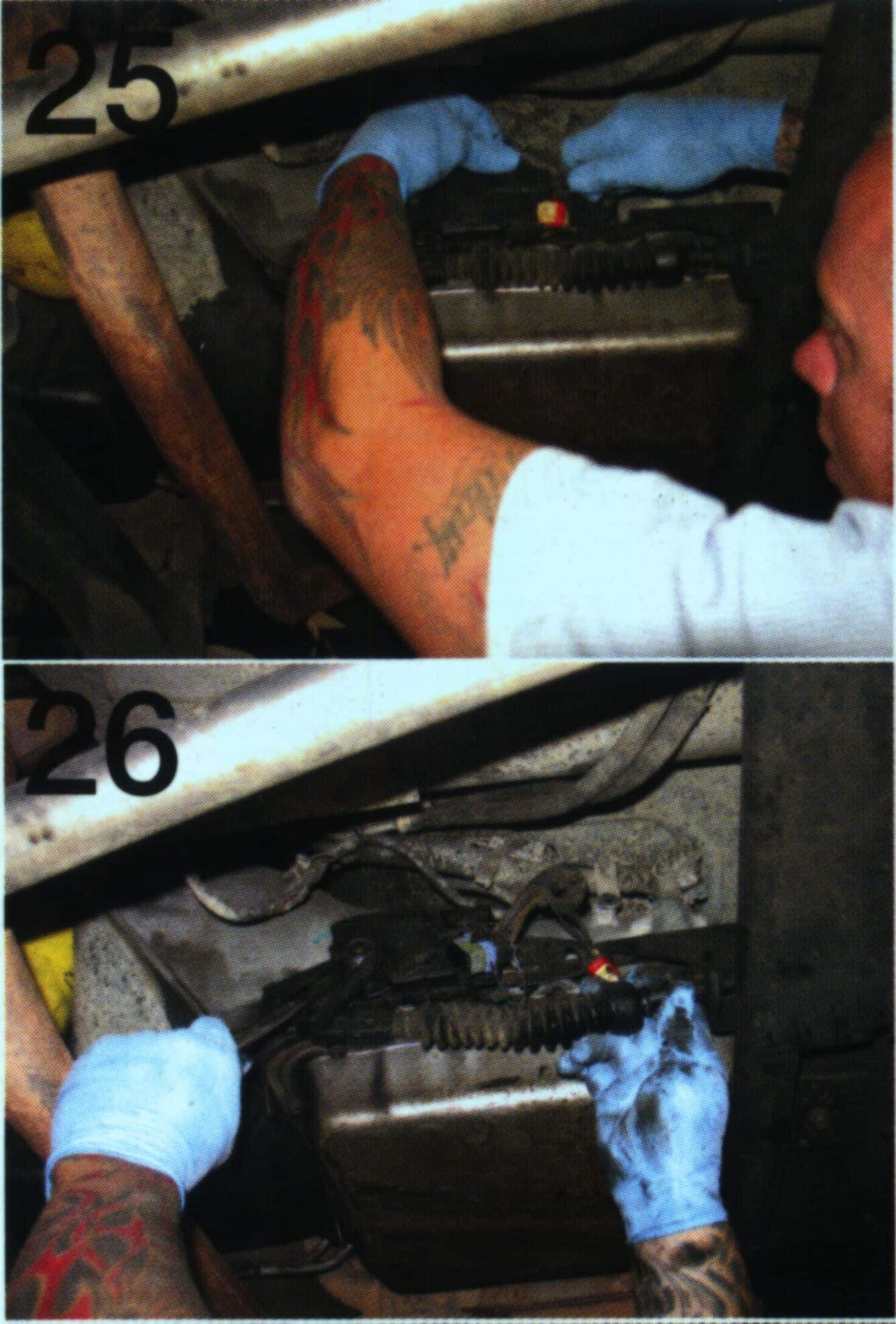

Back at IMZZ Industries in La Habra, California, Mike Bach put our project on the lift and started by unbolting the driveshaft at the pinion yoke. The driveshaft was pulled out and we moved on to clearing a path for the beat up factory 4L60-E to come out.

Mike unbolts the shift linkage and wiring harness from the side of the transmission.

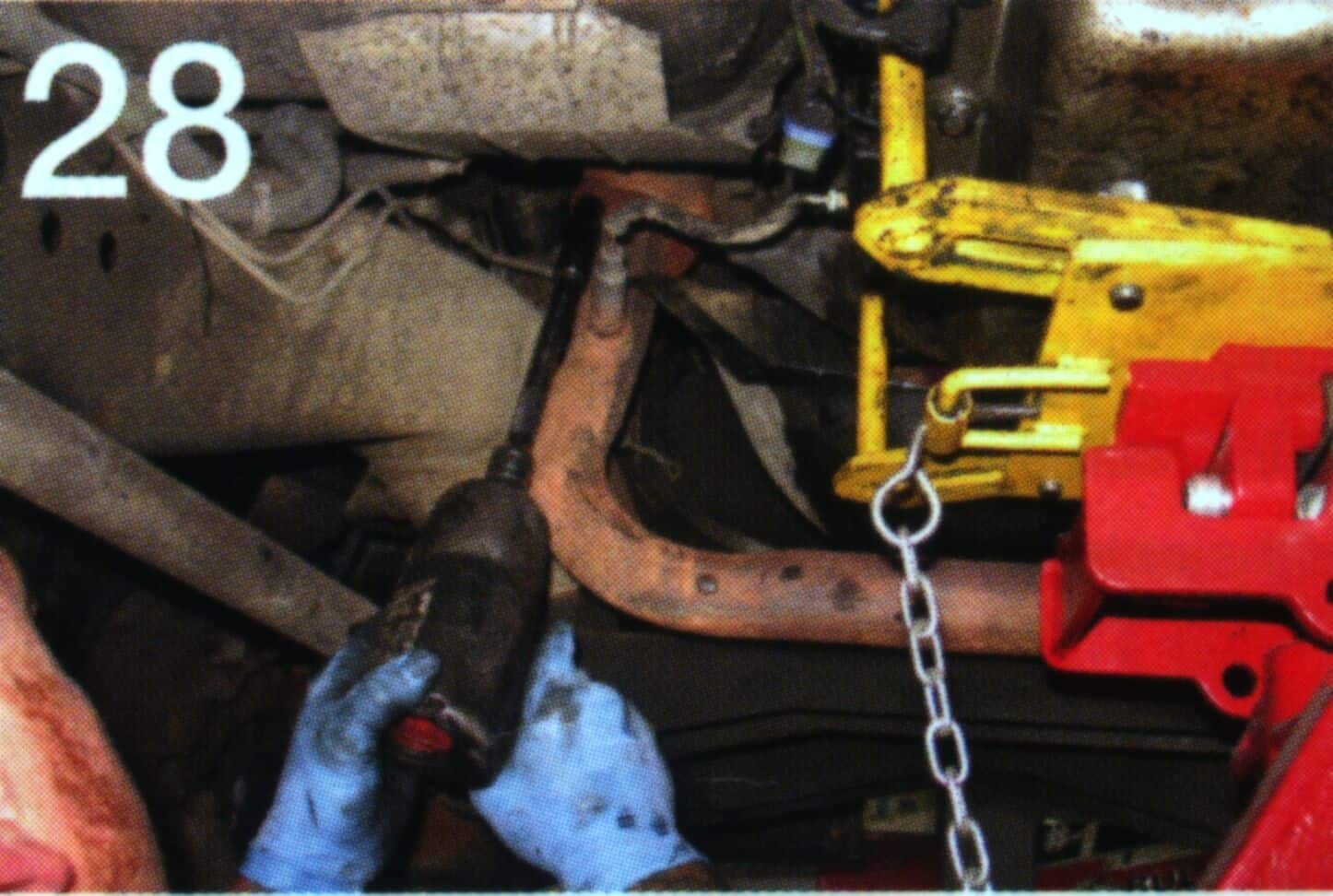

The transmission cross member is unbolted and will be slid out of the way for when we unbolt the transmission and get a transmission jack in place.

For a little extra clearance the exhaust had to be unbolted and removed from the catalytic converter forward.

With the scatter shield removed, we were almost ready to slide this wasted powe and torque transferring case out of the truck.

Mike rotates the flex plate with a flat blade to get at the converter bolts. Once a clear shot was in view he used an impact and socket to bust them loose.

The tired factory 4L60-E is out after Mike removed the bellhousing hardware and placed a transmission jack underneath to catch it. We were operating with the convenience of a lift, but if you are doing this job at home, remember to support the vehicle front and back with jack stands, work on a flat surface: take your time, and embrace safety.

The Gear Star 4L60-E is placed on the transmission jack and lifted into place.

Finally, Mike has the transmission back in the truck and is cranking down the bellhousing hardware with an impact, long extension and socket. The driveshaft was reinstalled and linkage and wiring harness hooked back up. After the exhaust crossover was bolted back up, we put the truck back on the ground and went for a drive. Power was restored and we now have a firm, positive-shifting gearbox that will rake any abuse we toss at it.