There was a time when drivability, low emissions, and high horsepower were topics of discussion and disputes. Nowadays, auto-shift cars feature speed, fuel economy, and power as vital features every car owner watches out for. These enhancements have also made it easier for car owners to abandon their gearshift. Nevertheless, selecting the correct torque for your automatic vehicle enables you to enjoy the full benefits of today’s technology. This is vital since the 4L80 torque converter links the engine to the transmission while tuning the connection to generate the most power while minimizing heat. Therefore, choosing the wrong torque converter can quickly thwart your dream of a dependable gear-banging since the reliability and power of drivability rely heavily on it. However, if you have plans to enhance your vehicle’s speed while getting excellent fuel mileage regardless of the shift pattern you’ve settled for, you have no choice but to fall right back to torque converter basics.

What Is a 4L80 Torque Converter?

A torque converter transmits an engine’s torque to the transmission. The transmission enables you to move the vehicle along the road. In simple terms, the torque converter connects the power source to the load via the transfer of rotating power from a prime mover to the rotating driven load. They are usually found in automatic transmission cars and efficiently replace the clutch system standard in manual vehicles.

How Does a 4L80 Torque Converter Work?

Transferring power from any powertrain to the transmission is a relatively complicated process. This is because several components move in synch at the same time. Of course, you know that you are just pushing the gas pedal with your foot, flipping a paddle, or moving a gearstick. But a lot goes on right under the floorboards. Each movement beneath the floorboard is carefully engineered and developed to allow for the seamless meshing of multiple components that propel your vehicle into motion.

In Manual Vehicles

A manual vehicle comes with a clutch assembly that gives rise to the connection and disconnection between the transmission and the engine, which drives the wheels. A throttle stop sets the idle of the engines, which signifies the minimum engine speed at which the engine can sit comfortably before it stalls as a result of a shortage of air/fuel mixture entering the cylinders. Without a clutch, the engine would stall when you slow your vehicle down to a stop because the transmission load would drag it far below its workable revolution limit. The clutch brings about the disconnection needed to keep the engine running smoothly and the re-engagement alongside some throttle to get the vehicle functioning again.

In Automatic Vehicles

However, in an automatic vehicle, no proper clutch exists. So instead, the clutch is replaced by a torque converter. The torque converter does the same job as a clutch: it allows the car engine to stay up and to run while the wheels and transmission slow down until they stop. But the torque converter goes about this assignment ingeniously and differently. The torque converter is also referred to as a fluid coupling, which transfers rotational energy via fluid movement from one automated system to another. The fluid coupling can replace the clutch because it can allow the car engine to rotate freely by significantly minimizing the torque delivery from the powertrain to the transmission. The torque converter never connects to the full, as you will feel via the ‘creep’ that occurs when you take off your foot from the brake of your automatic vehicle at a standstill.

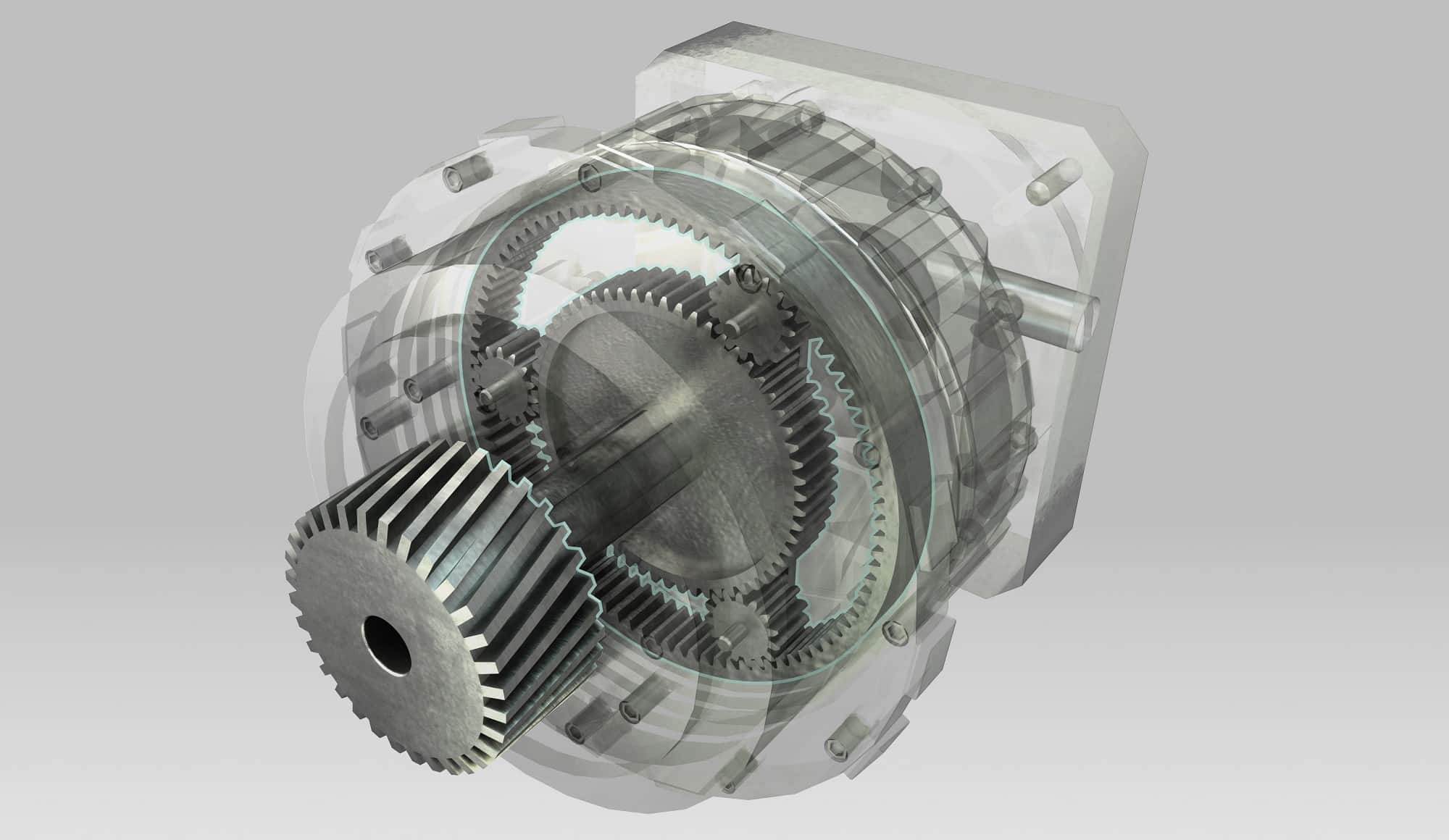

A pump that transmits fluid all over the torque converter helps achieve torque control. But this depends significantly on the crankshaft’s rotation. A turbine rotates within the torque converter as the pumped fluid gets in contact with the turbine’s vanes. This gauges the torque that will make it to the transmission via the input shaft. The torque converter’s casing is connected to the flywheel, which also spins at the exact rate of the crankshaft. Within this housing are a stator, the impeller or fluid centrifugal pump, and the turbine. The stator is a barrier to flinging the fluid back to the turbine instead of behind the pump. This action significantly boosts the efficiency of the system. In addition, the impeller flings the transmission fluid into the turbine fins, which, in turn, spin rapidly and transmit torque through to the transmission.

4L80 Torque Converter Basics

Here are a few ways you can speed up your vehicle using torque converter basics:

Maintain Your Car With Premium Fluids and Filters

Using high-quality filters and fluids helps combat excessive heat. However, you must watch out for how much heat your vehicle produces, which could affect how long it services your needs.

Ensure Your Transmission Cooling System Is Adequate

A cooling system helps regulate your engine’s temperature to avoid or prevent overheating. Irrespective of the quality of torque converter you opt for, you need to give more priority to combatting heat. You must consider pairing a cooling system with a high-quality filter and fluid.

Provide the Technician With Thorough Detail About Your Car

Torque converters are not one-size-fits-all. Instead, several manufacturing companies specialize in designing torque converters to fit a particular vehicle’s use and the driver’s specific needs. These companies showcase tech lines that potential clients can use to reach out to them to offer as much information as required about the customized torque converter to be constructed. Information can never be enough at this juncture. But ensure you include essential information such as camshaft specs, engine size, rear-end gear, and tire size.

Make Use of a Lock-Up Converter

A lock-up converter becomes useful for increased fuel mileage, reliability, and driveability. In addition, it can significantly minimize the heating issues of transmissions due to too much slippage from a higher-stall converter. Lock-up converters usually come in an overdrive-style transmission. However, this converter also showcases a clutch that creates a near-direct drive effect when engaged. This helps reduce slippage to the barest minimum, regardless of the stall speed, which successfully helps combat the heat that may potentially destroy the transmission.

Choose Your Camshaft Wisely

Converters and camshafts have a close relationship and could play significant roles in choosing the ideal converter for your vehicle. Camshafts determine the powerband of engine combinations to a very great extent. For instance, a 2,000 – 2,400-stall converter is an excellent choice when considering a cam duration of 248 degrees. On the other hand, a 2,400 or even 3,000-stall converter is much better for a cam duration of about 268 degrees, etc. These values portray that you will need a torque converter with just the right amount of stall for optimum performance while preventing heat generation. An additional advantage is that your engine can sit ideal in gear, especially if you use a stock camshaft. This is why it is crucial to determine the ideal stall speed.

The Bottom Line

The basics of a 4L80 torque converter are highlighted above to ensure you have a unit ideal for your vehicle. In addition, you can determine if the camshaft in your car is the most appropriate one or if a replacement will be needed. Everything boils down to the crucial factors to consider when settling for a torque converter that will always make you enjoy each minute you spend driving on the road.