A 3200 RPM stall converter (or torque converter) can enhance your 4L60E transmission’s performance for high-powered applications, whether that means ensuring you get the best launch from a standing start, or minimizing wear-and-tear for heavy-duty, high-torque driving. Whether you’re optimizing for the track or upgrading your vehicle’s capabilities, gain practical insights to make an informed decision about this transmission upgrade.

A performance engine paired with a stock torque converter often leaves power on the table, especially in high-octane driving scenarios. That’s where a stall converter comes in. Specifically, a 3200 RPM stall converter optimizes your 4L60E transmission, allowing the engine to operate within its sweet spot for power delivery.

Whether you’re looking for quicker launches at the track or better throttle response on the street, this upgrade transforms your driving experience.

What Is a Stall Converter?

Understanding Torque Converters:

A torque converter (or stall converter, if you prefer) is the unsung hero of automatic transmissions, managing the transfer of engine power to the drivetrain. Unlike a manual transmission’s clutch system, a torque converter uses hydraulic fluid to manage power delivery and ensure smooth acceleration. The “stall speed” refers to the maximum engine RPM the torque converter allows before it engages and transfers power.

What Does a 3200 Stall Converter Do?

A 3200 stall converter enables the engine to reach 3200 RPM before the torque converter fully locks, delivering power to the drivetrain. This higher stall speed ensures that your engine operates closer to its optimal power band, particularly useful for high-performance setups – such as getting a ripping, roaring start from a total stop.

With a specialized torque converter, your vehicle experiences better launches, quicker throttle response, and maximized power utilization. If you’re interested in drag racing, or even just high-performance street driving, upgrading your stall converter (especially if you’ve already hopped on a stronger engine) is a must.

How a 3200 Stall Converter Enhances Transmission Performance

Improved Acceleration:

A stock converter in a 4L60E is calibrated for comfort and efficiency rather than aggressive performance. A 3200 stall converter shifts the focus to quick takeoffs by letting the engine spin at higher RPMs before the drivetrain engages. This results in more immediate and powerful launches, giving drivers a competitive edge on the track.

Maximized Engine Performance:

Engines built for high performance often generate their best power at higher RPMs. A stall converter ensures that power delivery aligns with this peak range, or your ideal torque curve. For engines with performance camshafts, headers, or forced induction, a 3200 stall converter helps unlock their full potential by reducing low-RPM lag and boosting mid-range and high-RPM performance.

Enhanced Durability for High-Stress Driving:

In high-torque scenarios like racing or off-roading, the torque converter plays a critical role in managing stress on the transmission. A high-quality 3200 stall converter is built to handle this strain, reducing slippage and heat buildup, which extends the life of both the converter and the 4L60E transmission itself.

Considerations Before Installing a 3200 Stall Converter

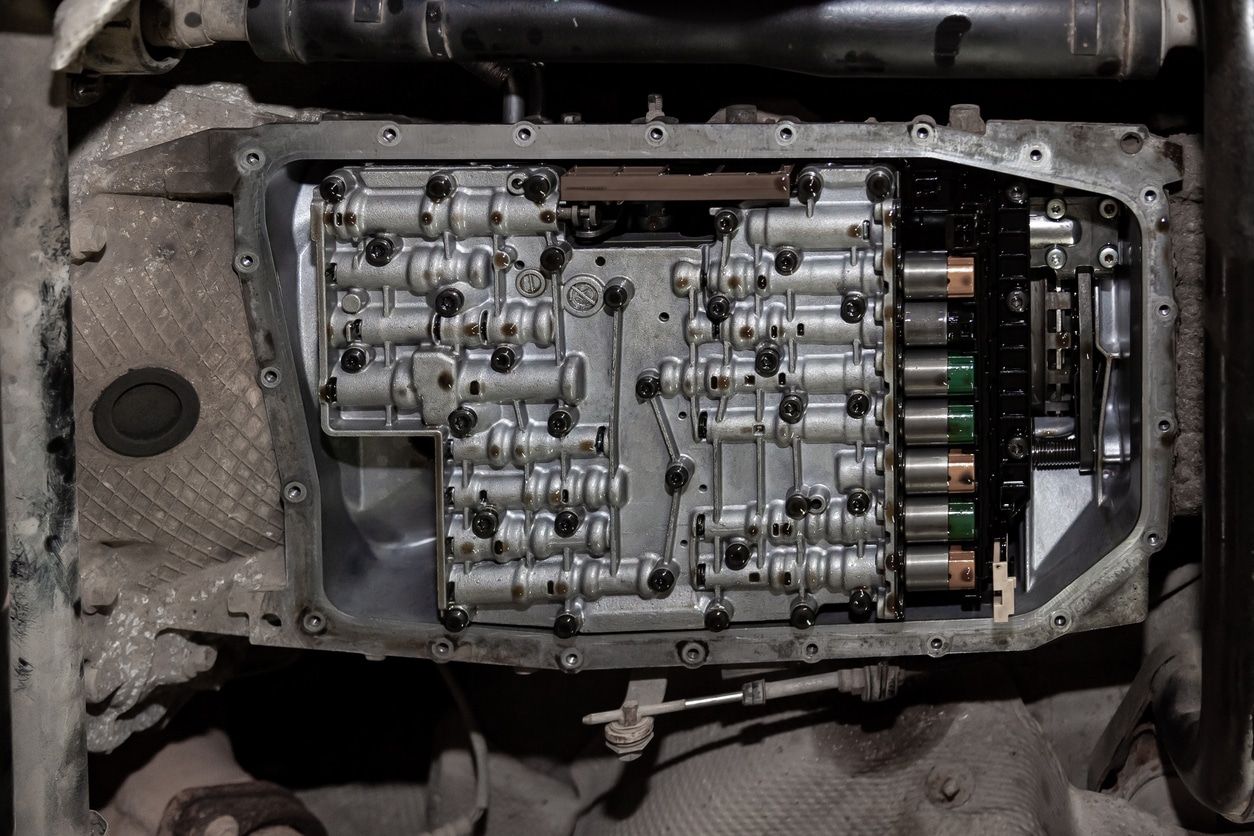

Compatibility with Your 4L60E:

Before installing a stall converter, assess the health of your transmission. Worn or damaged components can lead to failure when paired with a higher-stress application like a 3200 stall converter. Upgrading key components such as your input shaft and a transmission cooler ensures reliability under the increased demands. In other words, you’re always better off swapping most of the load-bearing parts out in a transmission designed for higher performance.

Daily Driving vs. Performance Goals:

A higher stall speed impacts drivability, especially in stop-and-go traffic. While a 3200 stall converter shines in high-performance scenarios, it may introduce quirks such as higher engine RPM at cruising speeds. It’s important to evaluate whether your primary use case justifies the trade-offs in daily driving comfort – and potential cost, regarding fuel efficiency.

Cost Implications:

Upgrading to a 3200 stall converter can range from a few hundred dollars for the part to several thousand for a full installation and supporting modifications. Consider your budget, the condition of your transmission, and whether this upgrade aligns with your overall build goals before committing.

Step-by-Step Guide to Installing a 3200 RPM Stall Converter

Preparation:

1. Gather Tools: Torque wrench, socket set, transmission jack, and experience are essential.

2. Verify Compatibility: Double-check that your chosen converter fits your specific 4L60E model and your vehicle’s performance profile. Torque converters are generally bespoke – double and triple check.

3. Fluid Drainage: Safely drain the transmission fluid to prepare for complete removal. Keep or dispose of it properly, if you intend to replace your transmission fluid!

Removing the Existing Torque Converter:

1. Use a transmission jack to safely lower the transmission from the vehicle.

2. Disconnect the driveshaft, cooler lines, and electrical connections.

3. Remove the bolts securing the existing torque converter to the flexplate, then carefully slide it off the input shaft.

Installing the New 3200 Stall Converter:

1. Prime the new converter by filling it with transmission fluid to prevent dry starts.

2. Align the converter with the input shaft, rotating it gently until it fully engages with the pump gears. You should feel multiple “clicks” as it seats correctly.

3. Attach the converter to the flexplate using bolts, ensuring they are torqued to the manufacturer’s specifications.

Reinstalling the Transmission:

1. Lift the transmission back into place and secure it with the mounting bolts.

2. Reconnect all wiring, cooler lines, and the driveshaft.

3. Refill the transmission with the recommended fluid and check levels after starting the vehicle.

Testing the Installation:

1. Start the engine and check for proper idle and gear engagement. If you’re using a transmission tuning software to monitor your transmission’s performance, make sure you’re seeing the shift response you want as you get the engine going.

2. Perform a low-speed drive to ensure smooth power delivery and identify any installation issues.

3. Monitor temperature and performance during a break-in period before pushing the converter to its limits.

Conclusion

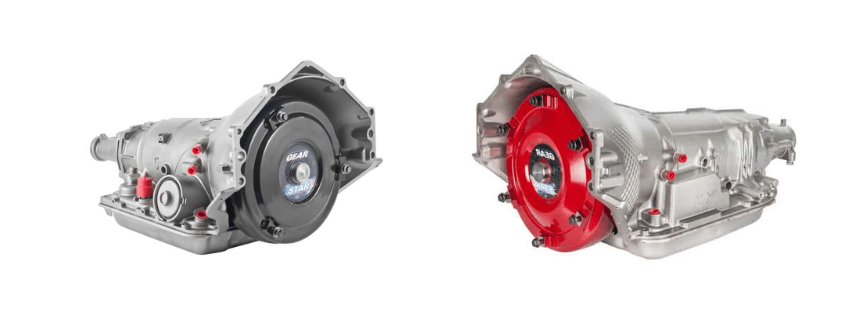

A 3200 RPM stall converter is more than just a bolt-on upgrade; it’s a transformative enhancement for the 4L60E transmission, particularly for high-performance builds. By aligning power delivery with the engine’s peak performance range, this upgrade delivers thrilling launches, consistent acceleration, and overall better handling of high-torque demands.

While installation requires careful preparation and consideration of costs, the results can elevate your vehicle’s performance to an entirely new level. Even if you’ve worked on your transmission in the past, a total rebuild is both a lot of work, and requires a certain degree of expertise – especially if you’re targeting a certain level of performance. Get in touch with us if you want to learn more about our rebuilt transmissions and transmission services.