Blog

If you’ve ever finished a round of engine upgrades: camshaft, intake, headers, maybe even EFI,

…

If there’s one thing GM got right with the 6L90 transmission, it’s that they built it to

…

This guide explains the 4R70W transmission controller, the electronic brain that commands shifts and

…

In the hierarchy of critical components inside a 4L80E, the direct drum rarely gets the attention it

…

What Is a Billet Direct Drum? Strength, Design, and Why It Matters

If there were a popularity contest in the world of transmission components, the direct drum might no

…

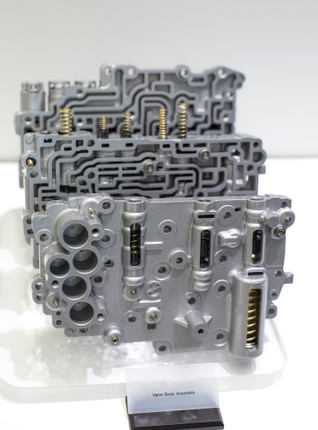

Valve Body Basics: What Does a Valve Body Do in a Transmission?

Few things are more frustrating than a built transmission that doesn’t respond the way it shou

…

For the first tech tip of the year, we are going to cover transmission cooler fittings. On our trans

…

There have been several different versions of the 4L60E over the years. They started in the mid 1990

…

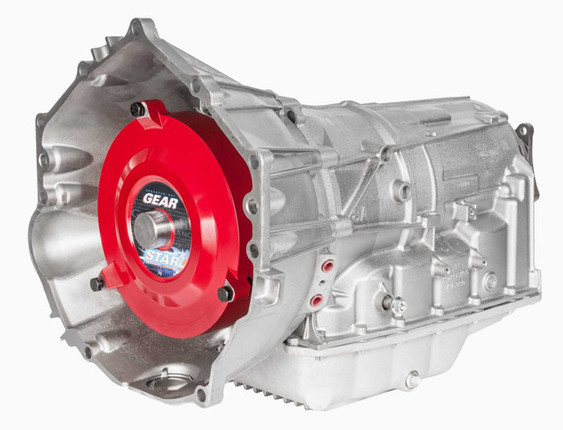

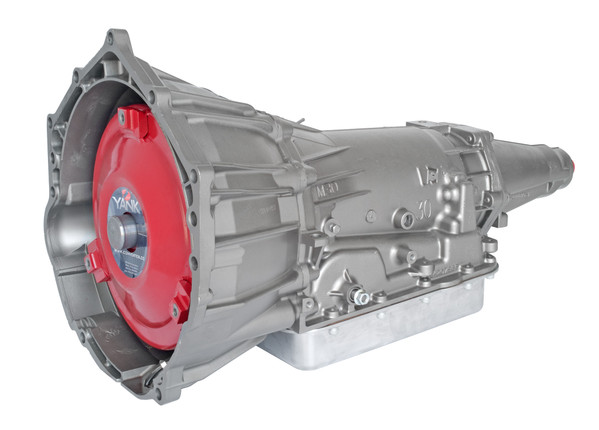

When building a high-performance vehicle, every component needs to keep up with your engine’s

…

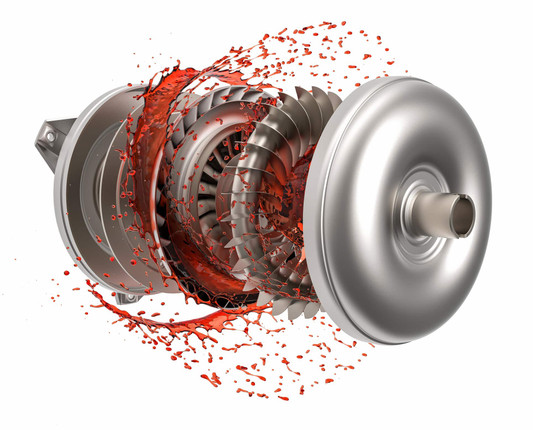

What Is a Torque Converter? Key Functions, Components, and Performance Benefits

If you’re building a performance car, refreshing a classic, or putting together a restomod, on

…

If there were a crown for “most mysterious car component,” the transmission would probab

…

Automatic Transmission vs Manual: What You Need to Know for Performance Builds

When building a performance car, restoring a classic, or assembling a street/strip machine, one of t

…