Essential 6L90 Transmission Upgrades

If there’s one thing GM got right with the 6L90 transmission, it’s that they built it to survive real work. Found behind heavy-duty trucks, performance SUVs, and high-torque applications, the 6L90 is often viewed as the “don’t worry about it” automatic. And to a point, that reputation is deserved. From the factory, it’s a strong, well-engineered transmission that can handle a lot more abuse than earlier six-speed designs.

But strong doesn’t mean bulletproof. Once you start adding power, towing heavier loads, or simply putting real miles on the truck, weaknesses begin to show. Heat creeps up. Clutches glaze. Lockup shudders under load. Shifts that once felt smooth start to feel lazy or inconsistent. And suddenly, 6L90 transmission upgrades don’t sound like overkill; they sound like insurance.

The key is understanding where the 6L90 starts to struggle and addressing those areas before minor wear turns into expensive failure. Let’s walk through the essential upgrades that actually make a difference, why they matter, and how to choose the right ones for your build.

Why the 6L90 Needs Upgrading in the First Place

From the factory, the 6L90 was designed to handle serious torque while maintaining smooth shifts and acceptable fuel efficiency. That balancing act works well for stock applications and light-duty use. The problem is that OEM transmissions are built around compromises, cost, emissions requirements, noise control, and mass-market drivability all factor into the final design.

Long-term durability under increased load usually doesn’t last in stock applications.

Common stressors that push the 6L90 beyond its comfort zone include increased engine torque, heavy towing or hauling, larger tires and altered gearing, aggressive driving or hard launches, and sustained high operating temperatures. Each of these factors adds strain in different ways, but they all share one common outcome: accelerated internal wear.

In most cases, a 6L90 doesn’t fail all at once. It slowly wears itself out. Small amounts of clutch slip create heat. Heat breaks down fluid. Degraded fluid reduces hydraulic control. Over time, that cycle snowballs. That’s why smart 6L90 transmission upgrades focus on reducing heat, improving holding power, and tightening control, not just making components “stronger” for the sake of it.

Torque Converter Upgrades: The Foundation of the Build

The torque converter is often the first place where problems show up, especially in trucks that tow, haul, or see frequent lockup under load. The factory converter is built for smooth engagement and efficiency at stock power levels, not repeated high-torque lockup events.

When a converter slips excessively, it generates heat fast, and that heat gets dumped straight into the transmission.

Upgrading the converter addresses several issues at once. A properly built unit improves lockup clutch holding power, reduces slip under load, manages heat more effectively, and allows the stall speed to be matched to how the vehicle is actually used. That last part is often overlooked.

For towing and daily-driven trucks, a modest stall speed paired with a stronger lockup clutch is usually the best choice. It keeps engine rpm in a usable range while preventing excessive heat buildup. Performance-oriented builds may benefit from a higher stall, but efficiency still matters, especially in heavier vehicles.

Multi-disc lockup converters are popular in upgraded setups because they spread load across multiple friction surfaces, allowing the converter to hold torque that would quickly overwhelm a factory single-disc design. When it comes to 6L90 transmission upgrades, a properly matched torque converter often delivers the biggest improvement per dollar and sets the tone for the rest of the build.

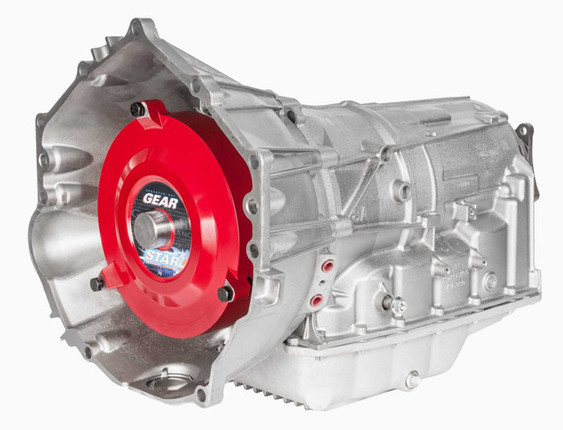

At Gearstar, our 6L80/6L90 converters are designed for longevity over the oem. Each features a billet cover and a billet lockup clutch with upgraded lockup clutch friction material.

Clutch Packs and Friction Materials: Where Power Is Actually Held

Inside the transmission, clutch packs are what actually transmit power from the engine to the drivetrain. When torque exceeds what the factory frictions can handle, the clutches begin to slip. Even small amounts of slip generate heat, and once that cycle starts, wear accelerates quickly.

Upgraded clutch packs typically involve higher-performance friction materials, increased clutch counts where possible, and improved steels designed to better tolerate heat. These upgrades allow the clutches to hold more torque without relying solely on higher line pressure, which can stress seals and hard parts over time.

The goal isn’t just brute strength. It’s to consistently apply pressure and predictable engagement across all driving conditions. Better clutches apply more evenly, release cleanly, and resist glazing under load. That consistency improves shift quality while also extending overall transmission life.

For trucks that tow frequently or vehicles running modified engines, upgraded clutch packs are a core part of effective 6L90 transmission upgrades and one of the best defenses against long-term failure, which is why they’re standard in our custom-built 6L90 transmissions.

Valve Body and Hydraulic System Enhancements

The valve body is the brain of the transmission’s hydraulic system. It controls when shifts occur, how quickly clutches apply, and how firmly those shifts happen. In stock form, it’s calibrated to prioritize smoothness above all else.

That’s fine for a grocery-getter. Less so for a truck doing real work.

Valve body upgrades that we include in our performance 6L90 transmissions recalibrate hydraulic flow to increase clutch apply pressure, reduce overlap and slip during shifts, improve consistency under load, and lower overall heat generation. Instead of soft, drawn-out shifts that wear clutches, the transmission engages decisively and efficiently.

This doesn’t mean harsh, neck-snapping shifts. When done correctly, valve body upgrades simply remove hesitation from the system. Shifts feel firmer because they’re cleaner, not because they’re aggressive. The result is less clutch wear, better control, and more predictable behavior when the transmission is under stress.

Among all 6L90 transmission upgrades, valve body modifications are often the most misunderstood, but also one of the most effective for improving longevity.

It’s important to note that for all 6l80/6L90 transmissions, the TECHM (Transmission Electro-Hydraulic Control Module) must be programmed to operate. If it is going into a factory application, the transmission must have the vin number flashed to match the computer.

At Gearstar, we flash every transmission with either the exact vin number or, if it is being controlled by a standalone controller, we will provide a VIN to best fit the application. We don't stop there. We will also go through the factory settings and change some of them to help improve the drivability, as well as the life of the transmission, for miles to come.

Hard Parts and Internal Reinforcements

Not every 6L90 needs billet shafts and reinforced carriers, but some definitely do. High-horsepower applications, heavy vehicles, and aggressive driving styles place enormous stress on rotating components inside the transmission.

Upgraded hard parts may include reinforced input shafts, stronger reaction carriers, and improved planetary assemblies. These components are designed to resist twisting, deflection, and fatigue under high torque loads.

That said, these upgrades are situational. Overbuilding wastes money and can introduce unnecessary complexity, while underbuilding almost guarantees failure, which is why consulting with a professional builder is key. They can help match internal reinforcements to realistic torque output, vehicle weight, and intended use.

When done thoughtfully, hard-part 6L90 transmission upgrades add durability where it’s actually needed, providing peace of mind without turning the transmission into an over-engineered science project.

Matching 6L90 Transmission Upgrades to How You Actually Drive

One of the most common mistakes people make is building a transmission for an imaginary version of their vehicle. Be honest about how it’s used day to day.

A daily driver benefits most from converter efficiency, upgraded clutches, and refined valve body calibration. A tow rig should prioritize lockup strength, clutch holding capacity, and hydraulic control under load. Performance builds place more emphasis on converter selection, clutch capacity, and internal reinforcements.

The best 6L90 transmission upgrades are the ones that support real-world usage, not occasional worst-case scenarios that rarely happen.

Final Thoughts: Smart Upgrades Beat Extreme Ones

The 6L90 is already a capable transmission. The goal of upgrading it isn’t to reinvent the wheel; it’s to remove weaknesses before they turn into failures.

By addressing the torque converter, clutch packs, hydraulic control, and internal strength as a complete system, you end up with a transmission that runs cooler, shifts cleaner, and holds up under real-world demands.

There’s no single “magic” upgrade. But done right, 6L90 transmission upgrades turn a good transmission into a dependable one—no matter how hard you ask it to work. Get in touch with the team at Gearstar today to learn how an upgraded 6L90 transmission may benefit your build.