Summary: Will a 4L80e swap-60E torque converter fit a 4L80E? The short answer is no. These transmissions have critical differences, such as input shaft design and spline count, that prevent direct compatibility. This guide breaks down the differences between the 4L60E and 4L80E transmissions, explains why a 4L60E torque converter won’t fit a 4L80E, and provides insights into potential workarounds.

If you’re diving into transmission work on a GM project vehicle, you may find yourself wondering: will a 4L60E torque converter fit a 4L80E? While these popular automatic transmissions share a lineage, their design differences make part swapping challenging. This guide addresses compatibility concerns, explores the key differences between the 4L60E and 4L80E, and discusses what’s needed to make such a transmission swap work.

The quick answer is that a 4L60E torque converter will not fit a 4L80E transmission. The input shafts of these transmissions differ, and their torque converters vary in size, spline count, and bolt patterns. However, with the right modifications, such as adapter kits and flex plate adjustments, you might make the swap, though this approach often comes with risks.

For those looking to enhance performance or compatibility, considering an aftermarket converter can be a viable alternative.

Understanding Torque Converters

What Is a Torque Converter?

A torque converter is a vital component in automatic transmissions. It transfers power from the engine to the transmission, multiplying torque and providing smooth gear transitions. In the absence of a manual clutch, the torque converter ensures efficient power transfer and performance.

An important aspect of torque converters is the ‘stall speed,’ which determines the maximum engine RPM at which the converter will hold back the engine before allowing it to turn the transmission.

Why Swap Torque Converters?

Torque converter swaps are often considered to enhance performance, improve efficiency, or adapt a vehicle for specific applications like towing or racing. However, compatibility is critical, especially when dealing with different transmission models like the 4L60E to 4l80e and 4L80E. It is also important to properly connect and manage cooler lines during a torque converter swap. Additionally, incorporating a lockup clutch can significantly improve efficiency during a torque converter swap.

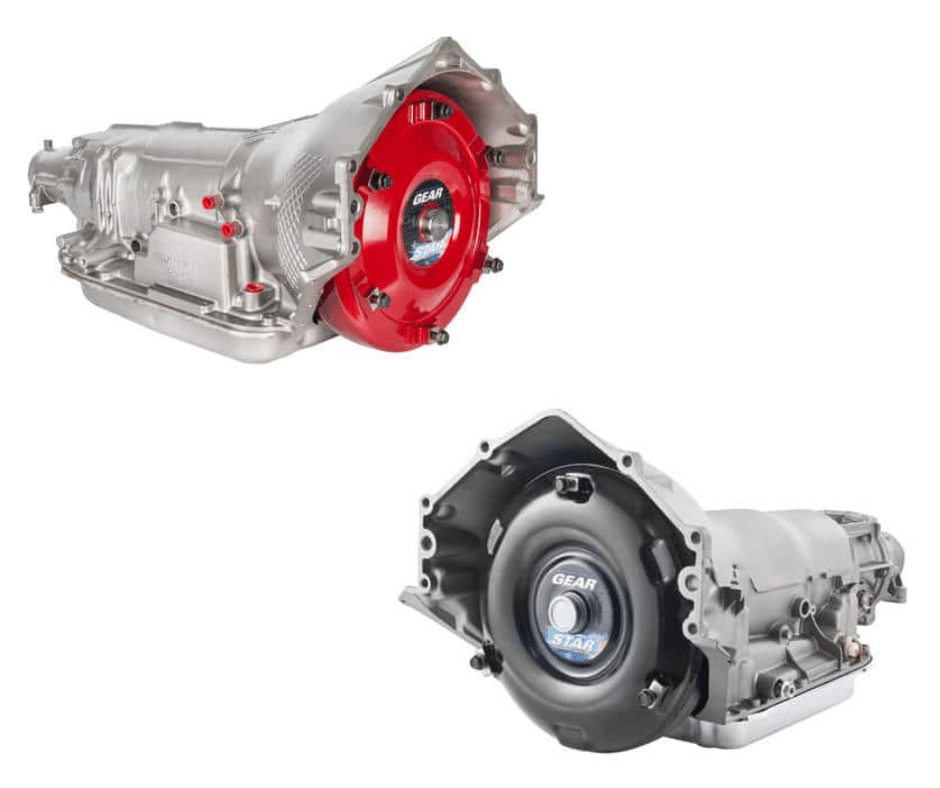

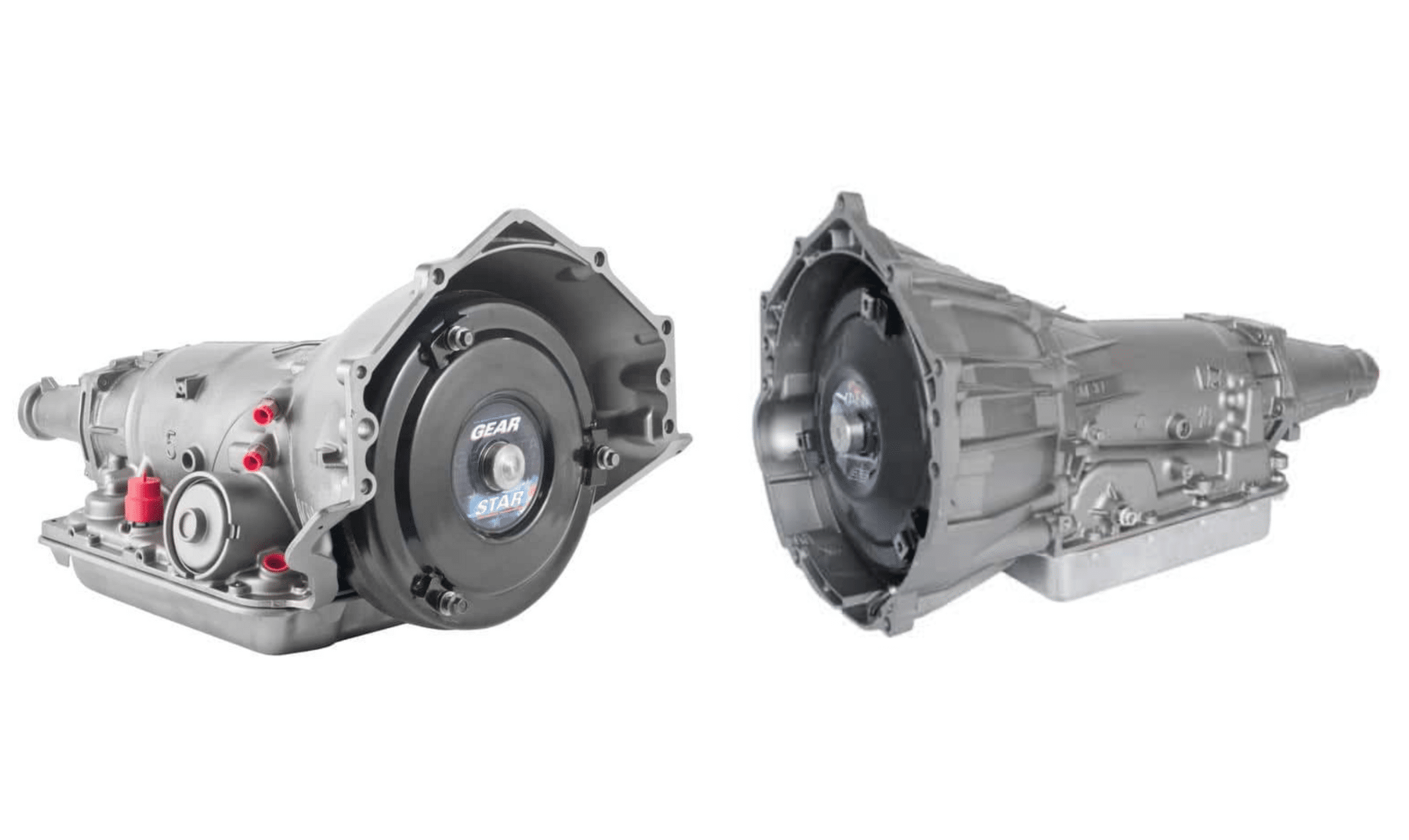

Key Differences Between the 4L60E and 4L80E

Input Shaft Design

The 4L60E is a lighter-duty, 4-speed automatic transmission commonly used in smaller trucks and SUVs. It’s designed for moderate torque and horsepower levels. By contrast, the 4L80E is a heavy-duty, 4-speed transmission built for larger trucks and high-torque applications. These design differences include:

- Input Shaft: The 4L60E features a 30-spline input shaft, while the 4L80E has a 32-spline input shaft, highlighting the difference in spline count.

- Torque Converter Size: The 4L80E’s torque converter is larger and more robust to handle increased power demands.

- Bolt Pattern: The 4L60E torque converter typically has a 3-bolt pattern, whereas the 4L80E uses a 6-bolt pattern.

- Bolt Holes: The bolt hole configuration may vary between the 4L60E and 4L80E, necessitating certain adaptations or equipment compatibility during a swap.

- Drive Shaft: The drive shaft may need to be modified or replaced due to the differences in length between the 4L60E and 4L80E, and a new yoke that fits the 4L80E may be required.

Gear Ratios:

- 4L60E Gear Ratios: 1st: 3.06:1, 2nd: 1.62:1, 3rd: 1.00:1, 4th: 0.70:1, Reverse: 2.29:1

- 4L80E Gear Ratios: 1st: 2.48:1, 2nd: 1.48:1, 3rd: 1.00:1, 4th: 0.75:1, Reverse: 2.07:1

The ‘overdrive’ gear in both the 4L60E and 4L80E transmissions helps improve fuel efficiency and reduce engine wear by lowering the engine RPM at higher speeds.

Why a 4L60E Torque Converter Won’t Fit a 4L80E

The key reasons a 4L60E torque converter isn’t compatible with a 4L80E are:

- Spline Count Mismatch: The 4L60E’s 30-spline input shaft does not align with the 4L80E’s 32-spline shaft.

- Bolt Pattern Differences: The torque converters use different bolt patterns, making installation impossible without modifications.

- Size Disparity: The larger torque converter in the 4L80E is designed for higher power and torque loads, whereas the 4L60E’s smaller converter cannot handle such demands reliably.

- Converter Hub Differences: The converter hub on the 4L60E is not compatible with the 4L80E, leading to further incompatibility issues.

Additionally, a compatible transfer case is necessary to handle the different spline counts and ensure proper function after the swap.

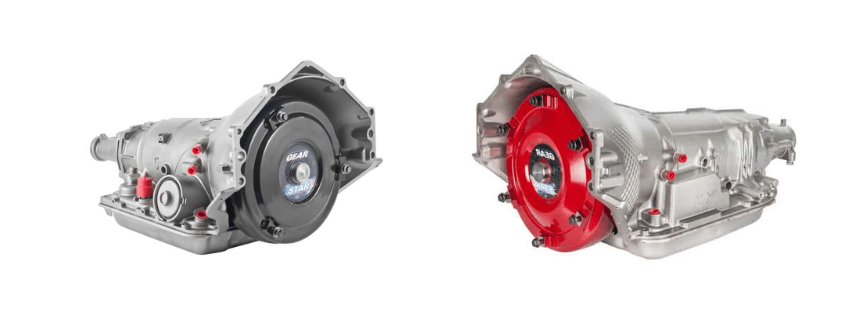

Can You Make It Work?

While a 4L60E torque converter won’t fit a 4L80E out of the box, there are modifications that can make this swap feasible:

- Converter Adapters: Adapter kits can address the spline count and alignment issues.

- Flex Plate Modifications: Modifying or replacing the flex plate may be necessary to match the bolt patterns and ensure proper fitment.

- Custom Tuning: Adjustments to the powertrain control module (PCM) and electronic systems are critical for compatibility.

For the most up-to-date advice and assistance tailored to your specific situation, consider starting a new thread in online forums.

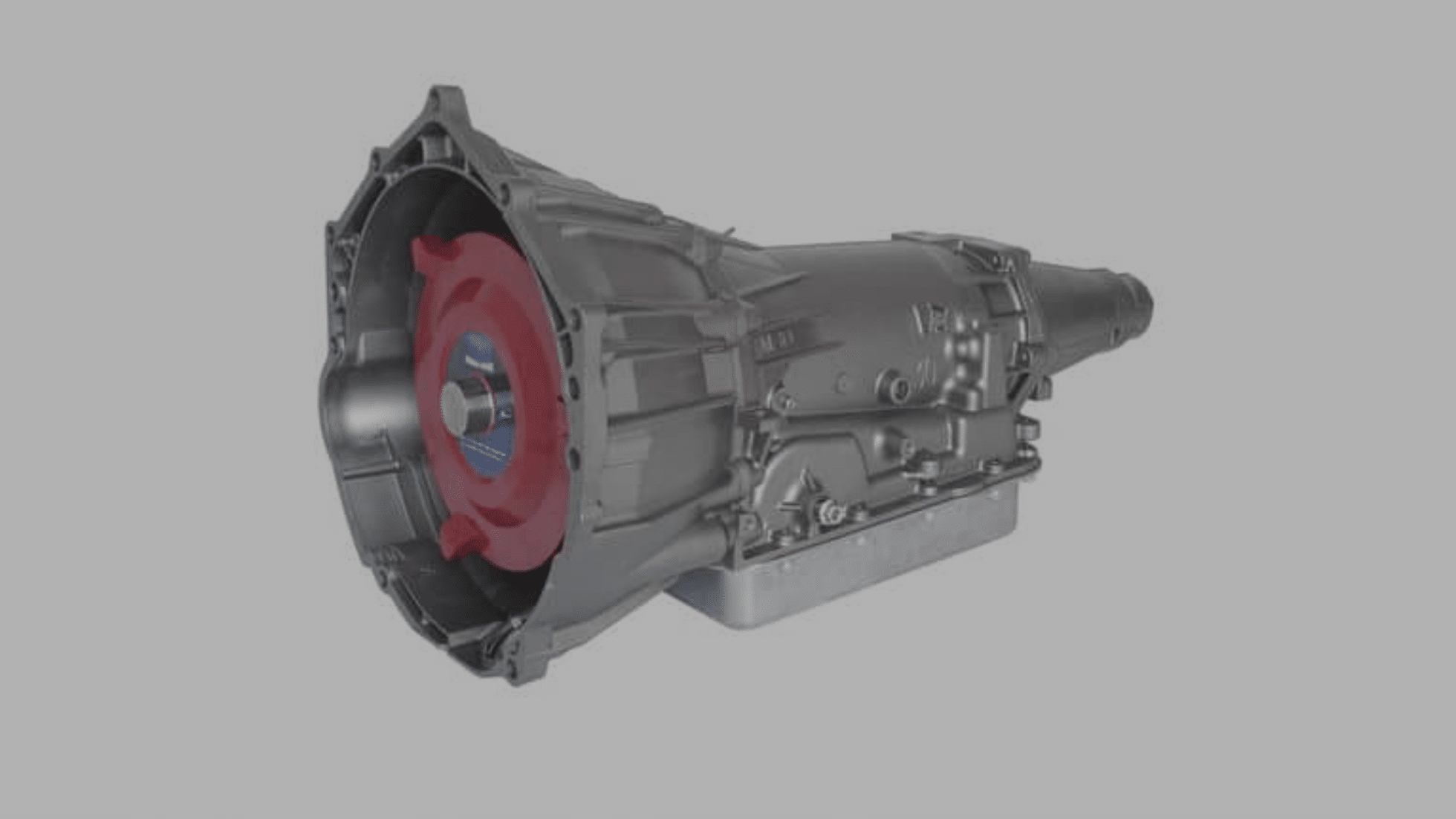

Performance and Reliability Risks of an Aftermarket Converter

Attempting to use a 4L60E torque converter in a 4L80E transmission can introduce several risks:

- Reduced Durability: The smaller 4L60E torque converter may not withstand the demands of a 4L80E transmission, leading to premature wear.

- Inefficient Power Transfer: Mismatched components can result in poor performance and inefficient power delivery.

- Increased Costs: Custom solutions can quickly add up, making it more practical to invest in a rebuilt 4L80E or an aftermarket torque converter designed for your application.

Investing in a high-quality aftermarket converter specifically designed for the 4L80E can enhance performance, improve drivability, and ensure quicker launches, making it a worthwhile investment. Additionally, proper heat dissipation is crucial for maintaining the performance and reliability of torque converters.

Conclusion:

So, will a 4L60E torque converter fit a 4L80E? Not without significant modifications. The differences in input shafts, spline counts, and torque converter sizes make a direct swap impossible. While adapters and custom solutions exist, they come with potential risks and costs.

For most applications, it’s more practical to invest in a torque converter designed specifically for the 4L80E or opt for a rebuilt transmission tailored to your needs. Consulting a transmission specialist can help you determine the best solution for your vehicle.

When seeking further information, avoid relying on an old thread or older thread in forums. Instead, seek current discussions or start new threads to ensure you receive the most accurate and timely responses.