Maximum Overdrive

Muscle car guys can call it character if they please, But there's nothing fashionable about single-digit gas mileage, subjecting your ears to a NVH beat down, or sweating like an Illinois governor. Late-models are all about knocking down 25 mpg on the way to the track, effortlessly clicking off 10-second passes while the muscle guys watch in disbelief. Yeah, baby. The problem is that if your 4L60-equipped fourth-gen actually runs that fast, it won't be long until the trans goes kaput. Not only is it ridiculously easy to eclipse the 500hp mark with either an LT1 or LS1 Camaro, the fact that fourth-gens are already anywhere from 7-to 16-years-old and usually have tons of miles on the clock-only compounds matters. Likewise, even the greatest of transmission builders have a tough time getting 4L60s to survive much past the mid-10-second mark. Perhaps the ideal solution is swapping in a heavy-duty 4L85E, and fortunately, Gearstar has it all figures out.

History has proven that the swap in question is an endeavor that's very common, yet rarely executed. Instead, hard-core enthusiasts often opt for track-proven three-speeds such as the TH350 and TH400. Some simply adjust to the ignominy of life without overdrive, while others bolt on a Gear Vendors assembly to the tailshift. Either option works just fine, but the 4L85E combines the best of both worlds. Essentially a TH400 with overdrive and more rugged internals, the GM 4L85E is the ultimate automatic. When built right, they can handle over 1,000 hp reliably, and best of all, transplanting one into a fourth-gen is much easier than Internet mythology suggests. "People are very intimidated by the 4L85E. They think that swapping it into a fourth-gen requires a lot of fab work, but that's just not true," says Zack Farah of Gearstar. "The trans tunnel does not need to be massaged anywhere, and there's very little cutting involved. It's not the cheapest option out there, but it's a long-term solution to a long term problem, and it's something you'll only have to do once. Getting the electronics to work isn't difficult at all, and you can even set it up with a full-manual valvebody which eliminates the need for a trans computer entirely."

To see if the swap is as easy as promised, we watched as Gearstar's technicians went to work on the company's 2000 Camaro SS. Much sooner than anticipated, the crew was done. We now see a growing population of 4L85E-equipped fouth-gens in the near future, but don't take our word for it. Read along and make the call for yourself

Gearstar’s test mule is a 2000 Camaro SS that packs a 444ci C5R-based LS1 with AFR heads, 13.0:1 compression, a big solid-roller cam, and a 300-shot of nitrous. As if 765 rear-wheel horsepower wasn’t enough for the driveline to deal with, the SS is a full-weight machine complete with power windows, steering, and door locks. The car has run deep 10’s on motor; indicative of 8-second potential on spray. Needless to say, with it’s dual role street/ strip inclinations, it’s the ideal recipient for a 4L85E upgrade.

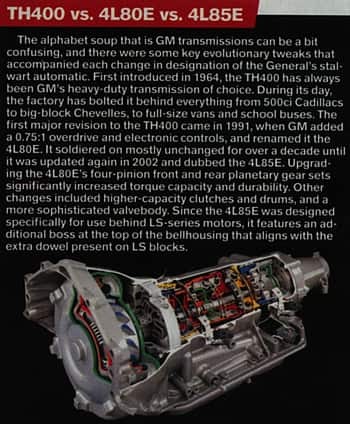

Since the 4L85E was designed specifically for LS-series motors, it features a boss at the top of the bellhousing-which is absent in the 4L80E-that mates with the extra dowel on LS blocks. For those seeking the simplest path to installing the ultimate overdrive into your fourth-gen, Gearstar has a complete bundled package that includes a 4L85E trans, custom crossmember, a Yank torque converter, and a custom-length heavy-duty steel driveshaft all for $5,000. For this particular swap, the mule sports an 11-inch billet 3,600-stall converter.

The first step in swapping the ultimate overdrive into a fourth-gen is removing the stock 4L60, which involves disconnecting the g-load brace, trans crossmember, torque arm, shifter, and driveshaft. Unlike the factory torque arm that attaches to the back of the transmission, this BMR unit anchors to a separate crossmember welded to the sub frame connectors, so removing it was not necessary. The commodious overall dimensions of the trans tunnel enables it to swallow up a 4L85E with next to no cutting or clearancing.

The 4L85E’s greater overall length requires moving the transmission mount location back roughly 3 inches. To accomplish this, Gearstar fabricated a custom transmission mount made from rugged 3/8-inch hardened steel that’s been powdercoated black. While this puts extra stress on the factory mount holes, Zack says that they’re more than up to the task since theyre reinforced from the factory. An optional front torque arm mount is available for cars that are still running the stock unit.

Made from flexible steel-braided hose, Gearstar’s custom trans dipstick eliminated the need to bend and wrestle with ridged tube when routing it through the chassis. Longer and larger in diameter than the stock piece, it doubles as a filter tube as well. An adjustable bracket enabled Gearstar to mount it on the cowl, although other locations will work as well.

In order to make it clear the long-tube headers, Gearstar removed 1 1/2 inches of metal off of the dust cover ear on the transmission case. While this procedure was preformed on a lathe, a die grinder will work just as well. Surprisingly, this was the only grinding necessary on the case to get it to fit.

The only cutting required was a 4-inch section of metal on the driver side of the trans tunnel just ahead of the crossmember. This provides clearance for the wiring harness bolt head. With the trans mocked into place, Gearstar technicians marked the area with a Sharpie, then cut and removed the metal section with a cutoff wheel. Since the metal flap isn’t a structural member, it has no adverse affects on chassis stiffness.

True to the car’s sleeker appearance. Gearstar removed the stock shift lever and mounted a B&M Pro Stick shifter inside the factory center console.

The B&M shift cable and trans brake line were routed through a factory hole located on the trans tunnel right above the crossmember mount. To get rid of some slack, the cables were angled rearward by attaching them to the fuel line with zip ties, then routed back forward on a gradual bend.

Should a transmission ever overheat, it’s designed to puke fluid out of the breather tube to relieve internal pressure. The factory tube is only three-to four inches long, and dumps fluid right on the case. To avoid a potential mess, Gearstar extended the tube all the way to the tailshaft housing.

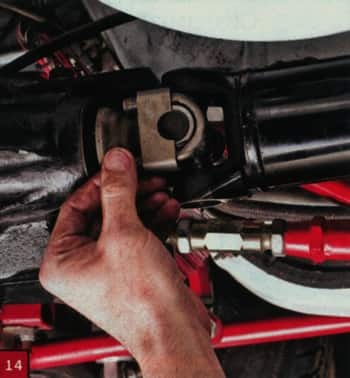

Not only is the slip yoke used on the 4L85E significantly larger than that of the 4L60E, it features 32 splines instead of 27. Gearstar matched the yoke up with beefy 1350 U-joints. The upgraded yoke assembly can be welded onto any driveshaft during the shortening process.

With the popularity of the TH400 swap, many manufactures offer torque converters that fit the LS1’s bolt pattern. This isn’t necessary with the 4L85E; as it was designed for LS-series motors from the get go. From this view, it’s clear where the dust cover area of the trans case will smack into the passenger-side header if it isn’t ground down. While it’s possible to dimple the Number 7 primary, the potential for impeding exhaust flow isn’t worth the risk.

With all the prep work complete, the 4L85E was raised into place. Needless to say, it fit beautifully beneath a fourth-gen and looks like a factory install. The custom fabricated low-profile Moroso trans pan features a rear-mounted pickup tube to avoid starvation at the dragstrip, and provides improved ground clearance over a stock 4L60E.

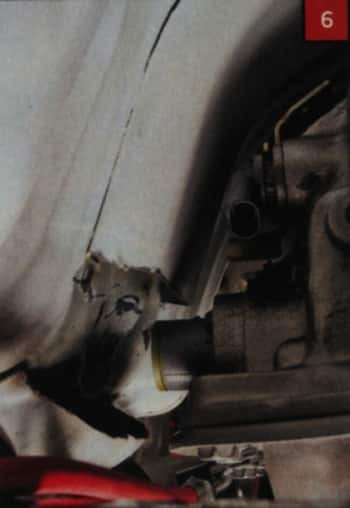

Gearstar prefers factory rubber transmission mounts in most street strip applications, but went with a custom urethane piece due to the SS’s 8-second potential. If the added vibrations are too harsh for your tastes, a factory GM 1LE rubber mount (PN 22146231) is a good alternative.

Measuring slightly longer than a 4L60E, swapping in a 4L85E requires shortening the driveshaft by 1/4 inch. Consequently, Gearstar installed a custom 3-inch-diameter heavy-duty steel shaft with 1350 U-joints and a 32-spline slip yoke. It’s affixed to the Moser 9-inch rearend with custom billet steel U-joint straps.

Measuring slightly longer than a 4L60E, swapping in a 4L85E requires shortening the driveshaft by 1/4 inch. Consequently, Gearstar installed a custom 3-inch-diameter heavy-duty steel shaft with 1350 U-joints and a 32-spline slip yoke. It’s affixed to the Moser 9-inch rearend with custom billet steel U-joint straps.

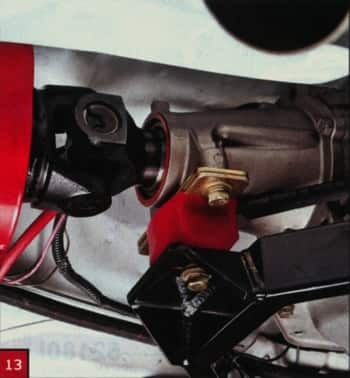

The final order of business underneath the car was securing the shift cable to the gear selector on the trans case using a lock washer, then attaching the cable bracket to the transmission pan rail.

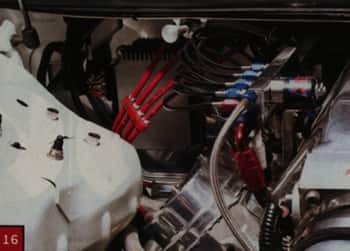

Mounted on the passenger side of the firewall where the heater box used to be, a GM Performance Parts Transmission control computer (PN 12497316) sends electronic signals to the 4L85E. Since it’s a standalone unit, the plug-and-play harness attaches directly into the transmission and doesn’t require splicing the factory wiring. The system includes the computer, a wiring harness, a software disk, and an interface cable that hooks up to a laptop. The software allows programming shift points, part-and-WOT shift firmness, and the final tune. Gearstar can also set up the 4L85E with a full-manual valvebody, which eliminates the need for a separate computer. Note the location of the cowl-mounted dipstick.

Prior to shipment, or installation in this stance, Gearstar runs all of its transmissions on a specialized dyno. Not only does this allow properly setting shift timing and firmness, it also breaks in the fresh clutches and steels, after which old fluid and debris is drained. Furthermore, the dyno can simulate engine and driveline load-which enables precisely dialing in converter stall speed-and replicate road speeds up to 130 mph. In essence, the dyno catches any potential problems before a transmission is bolted into a car.