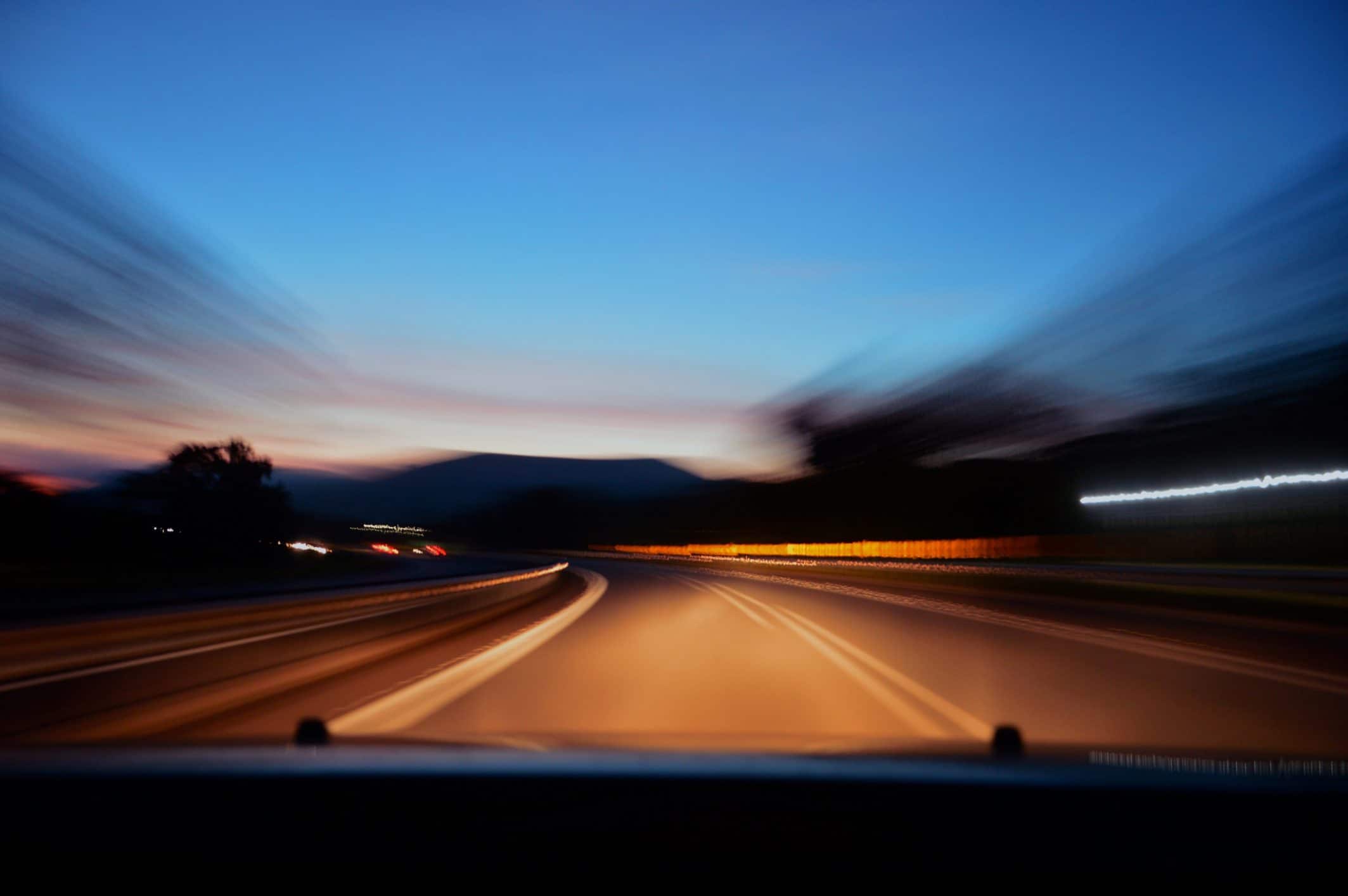

You have a high-performance vehicle alright, and you love to drive it fast and pull hard into corners. While that may give you the needed thrill and excitement, it could be causing a great deal of strain to your car’s OEM driveline and suspension fasteners.

The reason cannot be far-fetched since manufacturers have built these cars to handle regular driving. It’s evident in the quality of parts and the level of performance they can offer.

That is why putting more speed/force on the same load can take a toll on some components. Generally, high-stress environments can affect the reliability of the parts of your vehicle.

But hey, that can be kept at bay by having some important transmission tech tips that will ensure that while you get a great driving experience, that is not at the expense of your car’s functionality.

Tips to Maintain Quality Performance in Impact Driving

Here are some transmission tech tips that will enable you to maintain the quality of your ride. These are processes employed by Automotive Racing Products, Inc. (ARP), a manufacturer of car parts for racers and car builders.

ARP has designed and engineered several fasteners that can offer safety margins for a variety of applications. That being the case, you can find a repair shop that can also implement these changes on your vehicle.

1. Quality Wheel Studs

If you’re only going to pull your car on and off the road without trying out stunts, then the 8.8 or 10.9 rated metric studs it comes with is just right for it. The same can be said for the SAE equivalent Grade 5 (120,000 psi tensile strength) or Grade 8 (150,000 psi) the car comes with, which is suitable for normal driving.

On the contrary, if you’re going to be pulling 9 to 1.0+ G’s while driving a 3,500 – 4,000 lb. car, greater consideration has to be given since there are a lot of lateral forces that will be at play. What’s more, dumping the clutch at high RPM could multiply torque through the transmission and rear end, thereby leading to a strain on the studs.

These forces may take a toll on the ride, but the use of premium wheel studs can handle sideloads and ensure a breakdown does not happen. How’s that? You may wonder.

a. Using Quality Materials for Wheel Studs

Wheel studs that are made of quality materials are free of any laps, seams, or material impurities. This level of quality can be ensured by designing these materials from premium SDF/CHQ grades (which can be compared to aircraft quality) 8740 chrome-moly steel. The SDF in, this case, denotes that it is Seam and Defect Free.

b. Cold Forging of Wheel Studs

Asides from using quality materials to create wheel studs, the studs are cold-forged into an oversize blank. Which is then transferred to a heat treatment process- in a bid to attain a nominal rating of 190,000 psi.

The Wheel studs are then shot-peened, and CNC machined to a specific diameter and shape. Also, the threads are all rolled upon completion heat treating. It is worth noting that the threads are formed when the material is hard, instead of being cut or rolled before heat treating.

This way, the threads are of high quality. They have a fatigue strength that is ten times higher than other threads that are designed using common commercial methods.

As a result, the resultant product has precision and tolerance. The wheel studs can now handle the tremendous shock loads that may be evident when the clutch is dumped at a high RPM.

2. Quality Bolts

Designing clutch/flywheel and converter/flexplate bolts to be of high quality instead of relying on commercial specifications that only harden the case can be highly beneficial.

Also, certain considerations have to be made. Such as the design of the ARP flywheel and flexplate bolt to feature a 12-point head design; a large shank diameter to provide increased strength and improved flywheel register.

The use of a design of this nature can save you a lot of trouble. Especially if you tend to dump the clutch a clutch at a high RPM. A clutch dumped at high RPMs poses several concerns, including the easy failure of the converter/flexplate fasteners or conventional clutch/flywheel within the bell housing.

What causes this failure can be associated with the load mounted on the bolts as the clutch engages at high RPMs. Much more, a stiffer clutch will be more impactful upon release. A possible solution to this problem is to use the high-quality bolts, that are not only hardened at the case.

3. Ring gear Bolts

Ring gear bolts can also be damaged since excessive shear loads can be more at the rear end. Nonetheless, the gear bolts that can handle the power will be susceptible to help to curb any potential issues.

Specifically, the use of premium grade 190,000 psi tensile strength bolts will prove useful. It is advisable to get bolts in bulk due to the range of application and custom nature of some installations.

Some options in the market are 10-32 x ½” bolts to as large as ½” by 6-inch bolts. The bolts can also be polished stainless steel, thereby making them less susceptible to rust and corrosion.

Transmission Tech Tips Conclusion

These are the transmission tech tips you should employ in ensuring that the components of your high-performance car stand the test of time. It also means that you do not have to sacrifice hard racing, pushing the RPMs, or hard turning in corners.

A car whose wheel studs and bolts are of high quality can impact the level of performance that can be provided. That being the case, your ride will stand the test of time and serve you well in the long run.

Find a company that can put these transmission tech tips in place, all in a bid to revamp your ride. If you’re confident that it has been built to handle the power, then you can be more confident to give it hard turns.