What is the Difference Between a 4L70-E and a 4L75E? Key Variations Explained

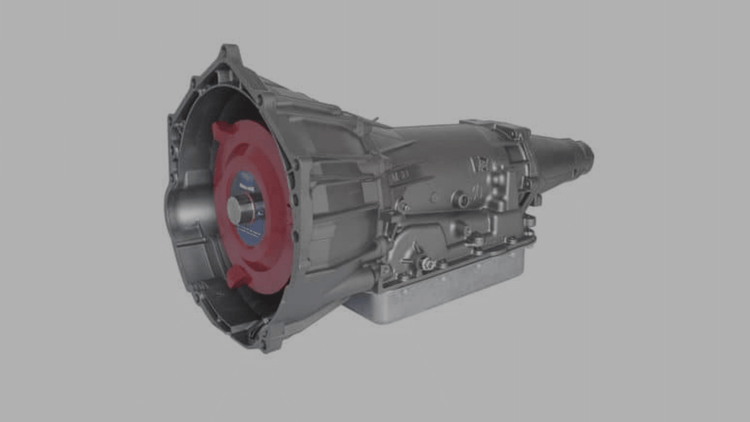

The 4L70-E and 4L75-E transmissions are both upgrades of the 4L60 series, but they differ in strength and design features. The 4L70-E includes an added input speed sensor as part of its enhancements, particularly in the 2005-2006 model years. The 4L75-E offers enhanced durability with stronger internal components, making it better suited for high-performance and heavy-duty applications. The 4L70-E, while reliable, is ideal for lighter-duty vehicles and offers slightly less torque capacity than the 4L75-E.

Both the 4L70-E and the 4L75-E are upgrades of the 4L60 series and part of GM’s storied and battle-tested automatic transmission offerings. Like previous generation transmissions, the 4L70-E and 4L75-E are 4-speed automatic transmissions with up to 5 gears. The jump from the 4L60-E and 4L65-E was made possible through lighter materials and a smarter build, resulting in better fuel efficiency, electronically controlled shifting, and more. The 4L70-E also marks the last time GM used the transmission design that first started with the 700R4.

Choosing between the 4L70-E and 4L75-E is a matter of torque. Both transmissions were built around the same era, and even share the same gear ratio. Differences in material and the total build result in drastically different torque limits, however, setting the 4L75-E apart as the heavy-duty workhouse of the duo. Let’s take a closer look at some of the other key differences. The 4L75-E is also ideal whenever you’re working on a car with a lot of power, but not enough space for the 4L80-E.

Differences in Gear Ratios Between the 4L70-E and the 4L75-E

First, a look inside. The 4L70-E utilizes 5-pinion planetary gearsets, which were an upgrade over earlier models like the 4L60-E, which featured 4. The internal components, such as the clutches and shafts, were strengthened to handle more torque compared to its predecessor while using lighter materials.

The 4L75-E, on the other hand, incorporates more heat-treated and induction-hardened components – specifically the stator shaft splines and the induction-hardened turbine shaft – improving its ability to withstand higher torque loads and harsh driving conditions. Specific valve body calibration also contributes to the increased torque ratings of the 4L75-E.

This enhanced build quality allows it to better resist wear, even under high torque and extreme conditions, making it more suited for performance vehicles and heavy towing.

As mentioned previously, the gear ratios between the two transmissions are the same:

- 1st Gear: 3.06

- 2nd Gear: 1.63

- 3rd Gear: 1.00

- 4th Gear (Overdrive): 0.70

- Reverse: 2.29

But the difference in torque load is immense. The 4L70-E is capable of handling around 495 lb-ft of torque. This makes it suitable for most light-duty trucks, SUVs, and performance vehicles but limits its use in very high-performance or heavy-duty applications.

The 4L75-E has a higher torque capacity of approximately 650 lb-ft, enabling it to handle more powerful engines and heavier loads. This makes the 4L75-E a better choice for high-performance vehicles and heavy-duty trucks – at least right out the gate. You can improve the torque limit on the 4L70-E with a custom build from us at Gearstar, by swapping out the input drum and the planetary gears with some stronger material. Of course, it’s always a question of getting the right setup for your project. While the 4L75-E has a higher power ceiling, it’s also larger.

Background on the 4L70-E and 4L75-E: Automatic Transmission Service Group

The 4L70-E transmission was introduced by General Motors (GM) as an evolution of the 4L60-E, a popular automatic transmission used in various GM vehicles. It debuted in 1992 and was designed to handle more torque and improve durability compared to its predecessors. The Automatic Transmission Rebuilders Association (ATRA) provides detailed specifications and historical evolution of the 4L70-E, highlighting its design changes and technical advancements.

The 4L75-E is what followed. As a natural progression from the 4L70-E, it offers even better strength and reliability, built for heavy-duty applications. Introduced around 2006, the 4L75-E came with upgraded internal components like improved gearsets, clutches, hardened input and output shafts, and better electronics. The Automatic Transmission Service Group (ATSG) is a credible source for information on the 4L75-E, offering specialized resources and detailed specifications for transmission rebuilders and enthusiasts. This evolution allowed it to handle even greater torque loads, catering to high-performance vehicles and heavy-duty applications.

GM aimed to enhance performance, fuel efficiency, and durability with both the 4L70-E and 4L75-E models. As fuel efficiency requirements continued to change, the goal became to develop transmissions that could handle the increasing demands of modern vehicles, especially those requiring more towing power and performance under heavier loads. GM also focused on improving the driving experience by optimizing shift smoothness and responsiveness through electronic control.

The 4L70-E and 4L75-E were primarily used in GM’s light-duty trucks, SUVs, and performance cars, like the Chevrolet Silverado, GMC Sierra, Cadillac Escalade, and Chevrolet Corvette.

Key Features of the 4L70-E: Specific Valve Body Calibration

When compared to its direct predecessor, the 4L60-E, the 4L70-E was designed to handle more torque with a maximum torque capacity of around 495 lb-ft. This was made possible through an upgrade from the 4-pinion gearset to a 5-pinion planetary gearset. Lightened materials meant better fuel efficiency, while improvements to the electronic control system resulted in smoother driving, better shifting, and lower fuel consumption. The introduction of the internal mode switch in 2009 replaced the external neutral safety switch and other components, further enhancing the transmission's design and functionality.

Like the 4L60-E, the 4L70-E had an overdrive gear (0.70:1), which improved highway fuel efficiency by lowering engine RPMs during high-speed cruising. The 4L70-E also incorporated upgraded clutch packs for smoother shifting and longer service life, particularly in high-performance or towing scenarios. Enhancements in internal wiring, including differences in wiring harnesses and solenoid functionalities, played a crucial role in the operational compatibility and design changes across different model years.

Last but not least, GM improved the hydraulic circuits in the 4L70-E to enhance fluid flow and heat dissipation, which reduced the risk of overheating and improved transmission longevity.

Key Features of the 4L75-E: Added Input Speed Sensor

The 4L75-E improved upon the 4L70-E with a torque capacity of around 650 lb-ft, making it suitable for even more demanding applications like high-performance trucks and muscle cars. The 4L75-E also features different bell housing mounting styles, which correspond to specific transmission features and installation requirements.

Internal components like the input shaft and output shaft were made of hardened materials to handle increased torque and reduce wear over time. This resulted in better performance and less frequent maintenance. GM also upgraded the clutch materials on the 4L75-E, allowing the transmission to endure higher levels of stress during heavy use or high-performance driving. The inclusion of the Corvette Servo further enhances the performance of the 4L75-E by improving shifting capabilities and overall transmission efficiency, especially for high-performance applications.

The valve body was also upgraded to provide quicker and smoother shifts under heavy loads, and a more efficient cooling system meant the 4L75-E did a better job of dissipating the higher thermal loads generated by high-performance engines.

Conclusion

While both the 4L70-E and 4L75-E share key features, the 4L75-E stands out with its enhanced internal components and higher torque capacity, making it more suitable for heavy-duty and high-performance applications. In cases where the full upgrade is overkill, a stock or modified 4L70-E will do the trick while weighing less. Ultimately, choosing between them depends on specific torque demands, with the 4L75-E offering more power and durability for tougher jobs.